RO water treating system and control method thereof

A water treatment system and water treatment technology, applied in the field of water treatment, can solve the problems of easy failure of high pressure switch and low pressure switch, adverse effects of booster pump and RO machine, frequent startup or disconnection of booster pump, etc. Achieve rich functions, increase water production efficiency, and save internal space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

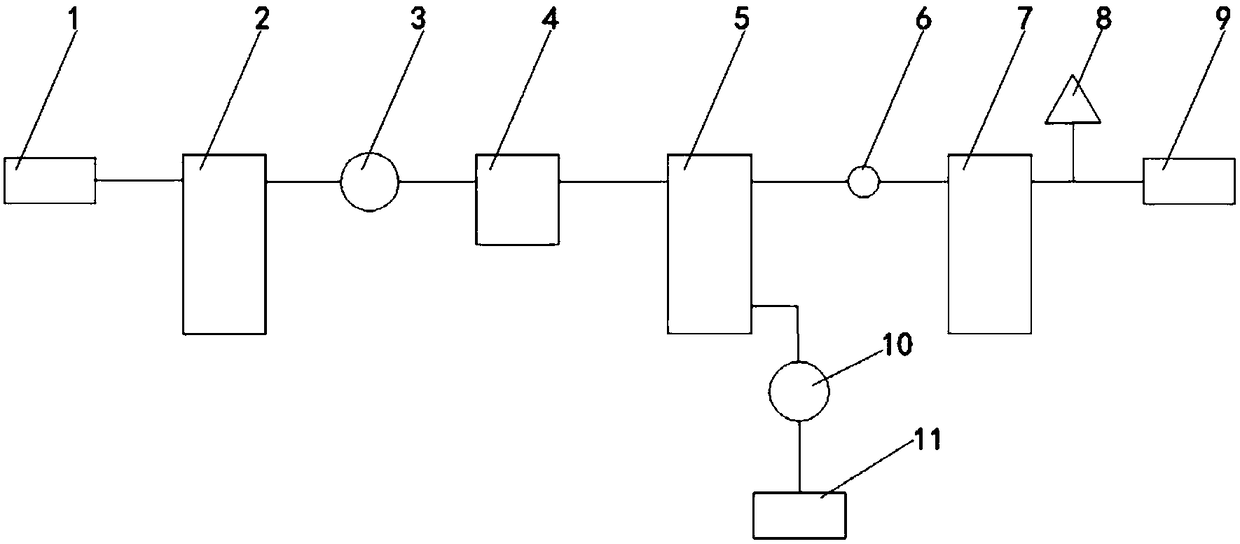

[0039] Embodiment: The present invention provides a kind of water treatment equipment, comprises RO water treatment system, and the structure of described RO water treatment system is as follows figure 1 As shown, including water treatment module, control module, booster pump, solenoid valve, check valve and pressure sensor;

[0040] The water treatment module includes a pre-filter unit 2, an RO filter element 5 and a post-filter unit 7; the water inlet of the pre-filter unit 2 is connected to the raw water inlet pipe 1, and the water outlet of the pre-filter unit 2 It is connected with the water inlet end of the RO filter element 5, the water outlet end of the RO filter element 5 is connected with the water inlet end of the post-filter unit 7, and the water outlet end of the post-filter unit 7 is connected with the clean water faucet 9 ;

[0041] The booster pump 4 is arranged between the pre-filter unit 2 and the RO filter element 5 and is connected to the water inlet end o...

Embodiment 2

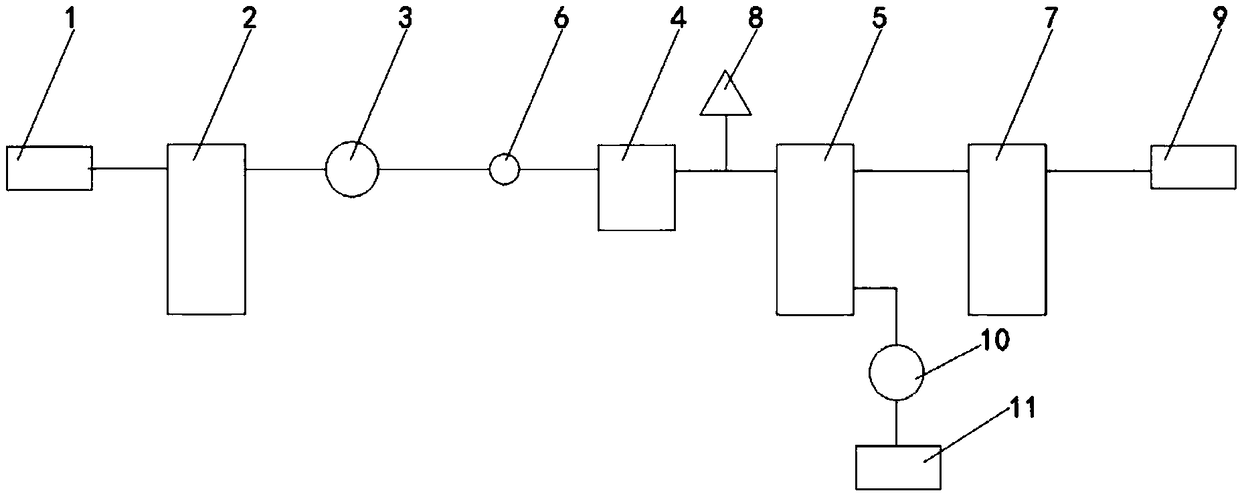

[0053] The structure of the RO water treatment system of the present embodiment is basically the same as that of the first embodiment, as figure 2 As shown, the RO water treatment system includes a water treatment module, a control module, a booster pump, a solenoid valve, a one-way valve and a pressure sensor;

[0054] The water treatment module includes a pre-filter unit 2, an RO filter element 5 and a post-filter unit 7; the water inlet of the pre-filter unit 2 is connected to the raw water inlet pipe 1, and the water outlet of the pre-filter unit 2 It is connected with the water inlet end of the RO filter element 5, the water outlet end of the RO filter element 5 is connected with the water inlet end of the post-filter unit 7, and the water outlet end of the post-filter unit 7 is connected with the clean water faucet 9 ;

[0055] The booster pump 4 is arranged between the pre-filter unit 2 and the RO filter element 5 and is connected to the water inlet end of the RO filt...

Embodiment 3

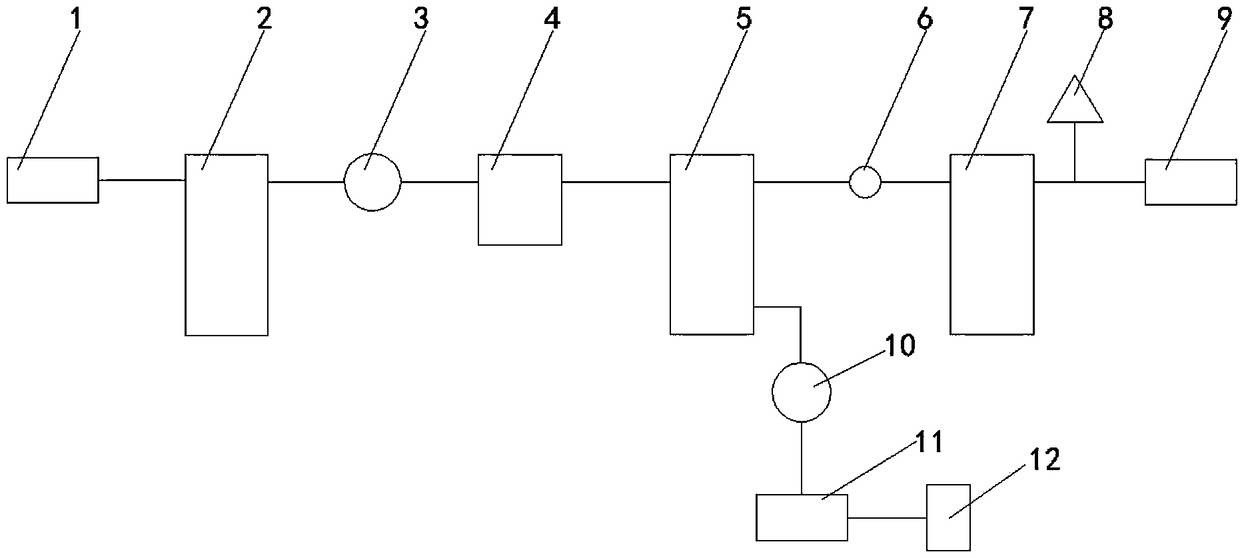

[0064] The structure of the RO water treatment system of this embodiment is basically the same as that of Embodiment 1, the difference is that the RO water treatment system of this embodiment includes a concentrated water storage tank 12, such as image 3 As shown, the concentrated water storage tank 12 is connected to the concentrated water outlet 11 of the RO filter element 5, and the concentrated water storage tank 12 is connected to a concentrated water outlet faucet. The concentrated water storage bucket 12 collects concentrated water and discharges it through the concentrated water outlet tap, which can be used as kitchen washing water (washing rice, washing vegetables, washing dishes, cleaning pots, wiping tables, etc.), effectively utilizing water resources, avoid wasting.

[0065] Preferably, a liquid level detection device is provided in the concentrated water storage tank 12, and the liquid level detection device is connected to the input end of the control module. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com