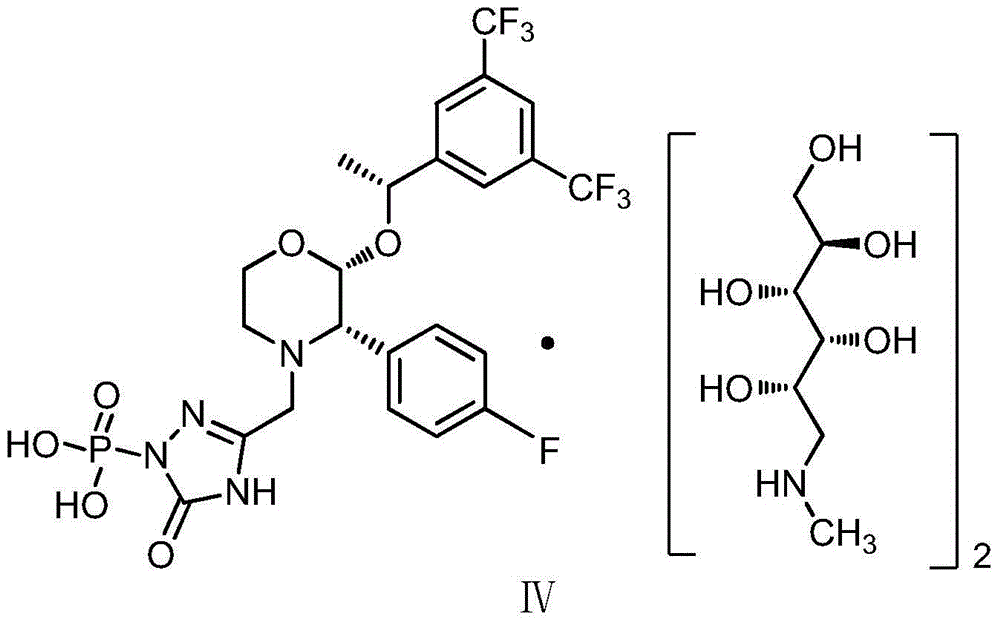

Preparation method of fosaprepitant dimeglumine

A technology of fosaprepitant dimeglumine and aprepitant dibenzyl phosphate, applied in the preparation of organic compounds, chemical instruments and methods, preparation of aminohydroxyl compounds, etc., can solve the problem of poor safety and is not suitable for industrialized large-scale production , cumbersome post-processing, many production processes, etc., to achieve the effect of avoiding excessive heavy metals, mild reaction conditions, simple and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

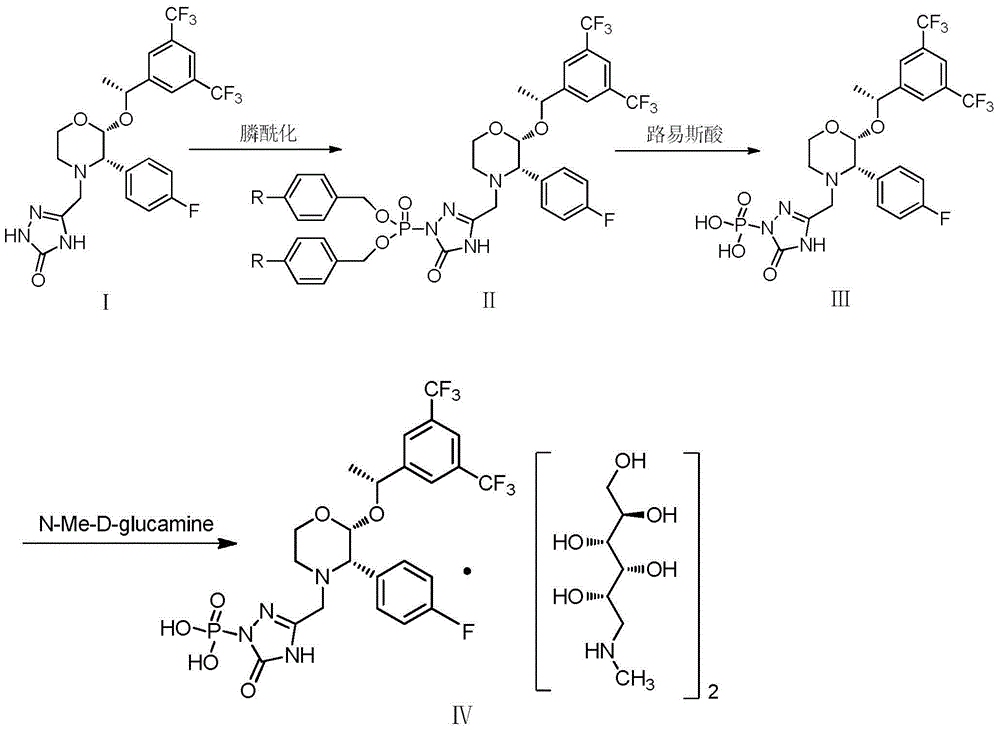

Method used

Image

Examples

Embodiment 1

[0031] Add 60ml of tetrahydrofuran, 5.3g of aprepitant and 7.0g of tetrabenzyl pyrophosphate into the reaction flask, stir to make it clear. Control the reaction temperature to 0°C, and slowly add 24ml of 1M sodium bis(trimethylsilyl)amide in tetrahydrofuran dropwise. The end of the reaction was monitored by TLC, the reaction was complete, 60ml of saturated sodium bicarbonate solution and 60ml of methyl tert-butyl ether were added, stirred, and allowed to stand for liquid separation. The organic layer was washed with 60ml 0.5M sodium bisulfate solution, 60ml saturated sodium bicarbonate solution and 60ml saturated brine, dried over anhydrous sodium sulfate, filtered, and the filtrate was concentrated to dryness to obtain 7.0g of product (II) with a yield of 88.8% .

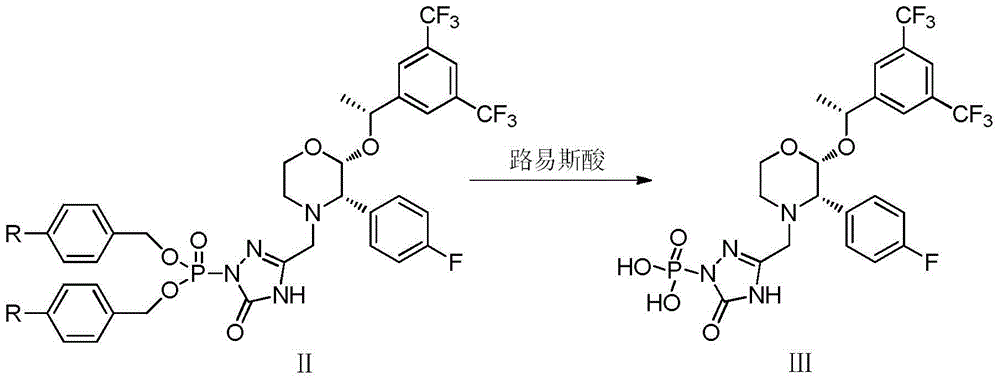

[0032] Dissolve 7.0g product (II) in 70ml methyl tert-butyl ether, control the reaction temperature at -5°C, and slowly add 2.6ml 1M BCl dropwise under the protection of nitrogen 3 Dichloromethane solution, after dr...

Embodiment 2

[0035] Add 60L of tetrahydrofuran, 5.3Kg of aprepitant and 7Kg of tetrabenzyl pyrophosphate into the reaction flask, stir to make it clear. Control the reaction temperature to 0°C, and slowly add 24L1M tetrahydrofuran solution of sodium bis(trimethylsilyl)amide. The end of the reaction was monitored by TLC, the reaction was complete, 60L of saturated sodium bicarbonate solution and 60L of methyl tert-butyl ether were added, stirred, and left to stand for liquid separation. The organic layer was washed with 60L 0.5M sodium bisulfate solution, 60L saturated sodium bicarbonate solution and 60L saturated brine, dried over anhydrous sodium sulfate, filtered, and the filtrate was concentrated to dryness to give product (II) 7.1Kg, the yield was 90 %.

[0036] Dissolve 7.1Kg product (II) in 70L methyl tert-butyl ether, control the reaction temperature at -5°C, and slowly add 2.6L 1M BCl dropwise under the protection of nitrogen 3 Dichloromethane solution, after dripping, TLC monitors t...

Embodiment 3

[0039] Add 60ml of tetrahydrofuran, 5.3g of aprepitant and 7.73g of tetra-p-methylbenzyl pyrophosphate into the reaction flask, stir to make it clear. Control the reaction temperature to 0°C, and slowly add 24ml of 1M bis(trimethylsilyl) sodium amide solution in tetrahydrofuran dropwise. The end of the reaction was monitored by TLC, the reaction was complete, 60ml of saturated sodium bicarbonate solution and 60ml of methyl tert-butyl ether were added, stirred, and allowed to stand for liquid separation. The organic layer was washed with 60ml 0.5M sodium bisulfate solution, 60ml saturated sodium bicarbonate solution and 60ml saturated brine, dried over anhydrous sodium sulfate, filtered, and the filtrate was concentrated to dryness to obtain product (II) 6.53g, the yield was 80% .

[0040] Dissolve 6.53g of product (II) in 70ml of isopropyl ether, control the reaction temperature at -5°C, and slowly drop 0.8ml of 1M BCl under the protection of nitrogen 3 Dichloromethane solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com