Cold forming process for non-ferrous metal seam elbow

A non-ferrous metal and cold forming technology, which is applied in the field of non-ferrous metal seamed elbow cold forming technology, can solve the problems of high performance requirements of forming equipment, high overall cost, and large application prospects, so as to avoid excessive wall thickness reduction and prevent The effect of excessive thinning and exceeding the standard and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] C-276 nickel-based alloy elbow with a forming specification of 90E(L)Φ48.3mm×2.77mm:

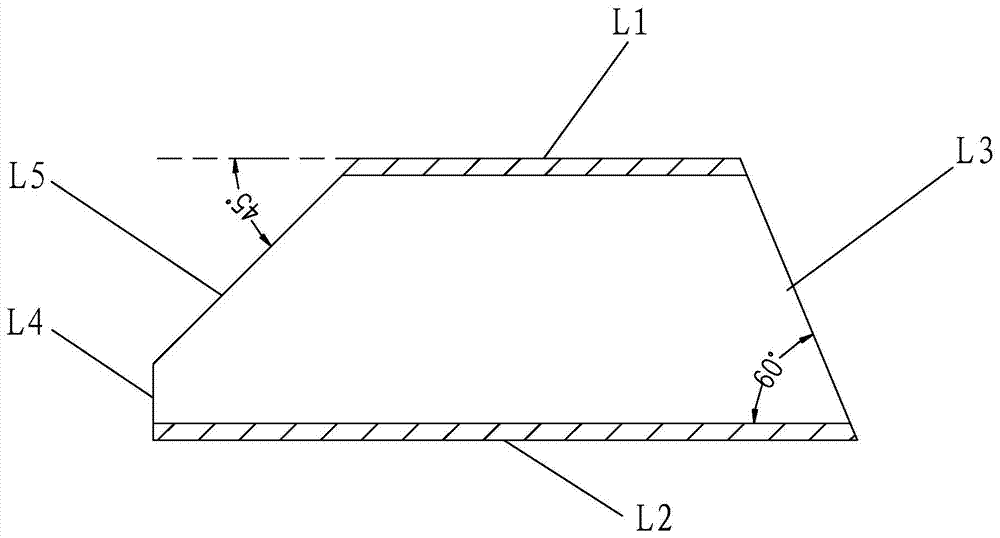

[0037] Step 1. Using C-276 nickel-based alloy seamed tube blank as raw material, remove the weld reinforcement on the outer surface of the seamed tube blank, and remove the weld outer surface with reinforcement according to JB / T4730.5-2005 Carry out 100% PT non-destructive testing, grade I is qualified, then cut the seamed pipe blank into processed pipe fittings with oblique cuts at both ends, and make the weld on the inner surface of the processed pipe fittings be located on the long side of the processed pipe fittings; figure 1 As shown, the section of the processed pipe fitting along the central axis and the centerline of the weld is a pentagon, and the upper side L1 of the pentagon (that is, the short side described in step 2) is parallel to the lower side L2 (that is, the long side), The angle between the first hypotenuse L3 connecting the upper side L1 and the lower side L2 and ...

Embodiment 2

[0045] C-276 nickel-based alloy elbow with a forming specification of 90E(L)Φ114.3mm×3.05mm:

[0046] Step 1. Using C-276 nickel-based alloy seamed billets as raw materials, conduct RT non-destructive testing on the welds on the inner and outer surfaces of the seamed pipe billet, and the welds on the outer surface of the seamed pipe billet are removed. Reinforcement, according to JB / T4730.5-2005, carry out 100% PT non-destructive testing on the outer surface of the welded seam with reinforcement removed, and the I level is qualified. Make the weld on the inner surface of the processed pipe fittings be located on the long side of the processed pipe fittings; figure 1 As shown, the section of the processed pipe fitting along the central axis and the centerline of the weld is a pentagon, and the upper side L1 of the pentagon (that is, the short side described in step 2) is parallel to the lower side L2 (that is, the long side), The angle between the first hypotenuse L3 connectin...

Embodiment 3

[0054] TA2 pure titanium elbow with a molding specification of 90E(L)Φ219.1mm×3.76mm:

[0055] Step 1. Using TA2 pure titanium seamed billet as raw material, carry out UT non-destructive flaw detection on the welds on the inner and outer surfaces of the seamed pipe billet, and the I level is qualified, and remove the weld reinforcement on the outer surface of the seamed pipe billet. According to JB / T4730.5-2005, 100% PT non-destructive testing is carried out on the outer surface of the welded seam with reinforcement removed, and the grade I is qualified, and then the seamed pipe blank is cut into processed pipe fittings with oblique cuts at both ends, and the processed pipe fittings are processed. The weld on the inner surface is located on the long side of the processed pipe; for example figure 1 As shown, the section of the processed pipe fitting along the central axis and the centerline of the weld is a pentagon, and the upper side L1 of the pentagon (that is, the short sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com