Cooling process for eliminating banded structure of steel ingot

A technology of strip structure and cooling process, applied in the field of steel ingot cooling, can solve the problems of excessive strip structure of steel ingot, inconsistent cooling speed, large difference in cooling speed, etc., so as to eliminate the influence of temperature, facilitate use, and avoid strip structure exceeding the standard. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A cooling process for eliminating the banded structure of steel ingots, the specific steps are as follows:

[0039] (1) Before pouring, install the middle injection pipe and steel ingot mold on the pouring bottom plate;

[0040] (2) Start pouring after installation;

[0041] (3) Prepare the ventilation and cooling device in advance, and hoist the ingot air cooling device between the center injection pipe and the ingot mold within 5 minutes after pouring;

[0042] (4) Turn on the air compressor, and the cold air is blown out from the outlet hole of the air outlet pipe to cool the steel ingot. The cooling procedure is as follows:

[0043] A. Control the outlet pressure of the air compressor to 0.1MPa, and cool down by air cooling for 1 hour;

[0044] B. Adjust and control the outlet pressure of the air compressor to 0.15MPa, and continue to cool down for 1 hour;

[0045] C. After 2 hours of air cooling, turn off the air compressor and stop the ventilation; hang out the...

Embodiment 2

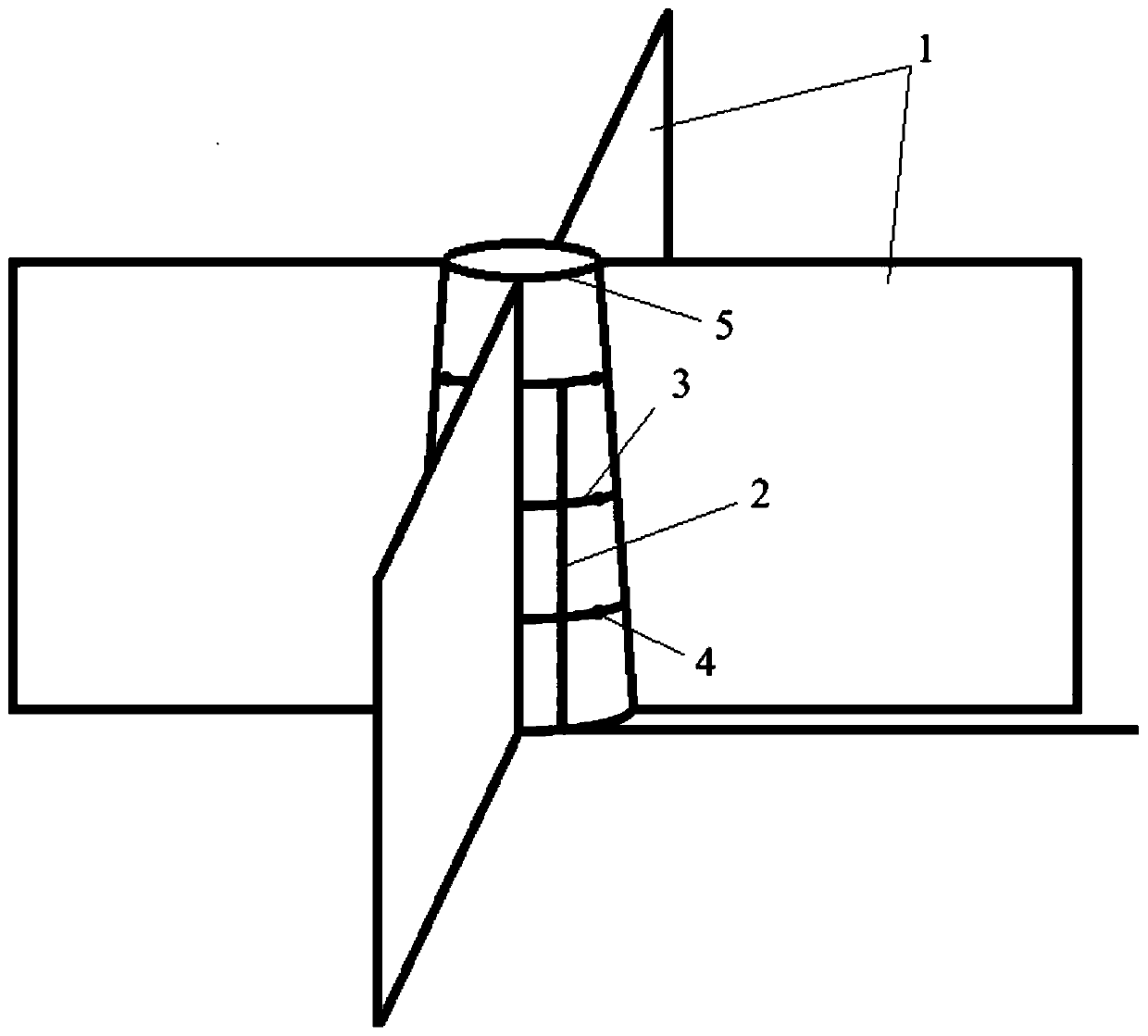

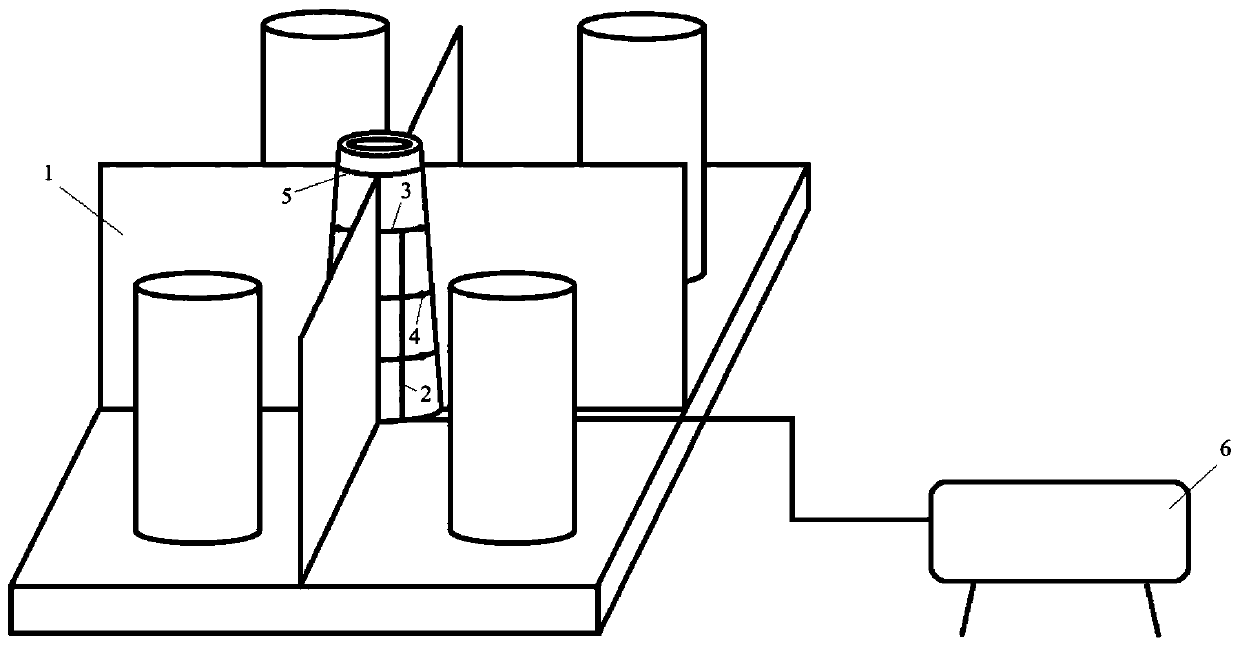

[0048] On the basis of Embodiment 1, the steel ingot air cooling device includes a gas pipeline, an air compressor 6 and a thermal insulation baffle 1 . The ingot air-cooling device is a frame structure, and the frame size matches the center column pipe; the gas pipeline includes an air inlet pipe 2 and an air outlet pipe 3; the air inlet pipe 2 and the air outlet pipe 3 are connected; the air outlet pipe 3 is horizontally circular Set, the number is 3; the outlet pipe 3 is provided with an outlet hole 4 facing outward; the diameter of the outlet hole 4 is 1 to 2 mm, and the number is 4 and arranged equidistantly; the air inlet pipe 2 One end is connected with the air compressor 6; the inlet pipe 2 and the outlet pipe 3 are steel pipes with a diameter of 20mm, and the material is Q235 steel; the heat insulation baffles 1 are 4, arranged in a cross; the heat insulation baffles 1 is connected with the air outlet pipe; the upper and lower ends of the heat insulation baffle 1 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com