Method for producing degradable plastics by using activated sludge

A technology of activated sludge and degradable plastics, applied in sludge treatment, biological sludge treatment, etc., can solve problems such as soil and air secondary pollution, impact on water quality and shipping, and ecological environment damage, and achieve high production efficiency and increase The ability to purify the air and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

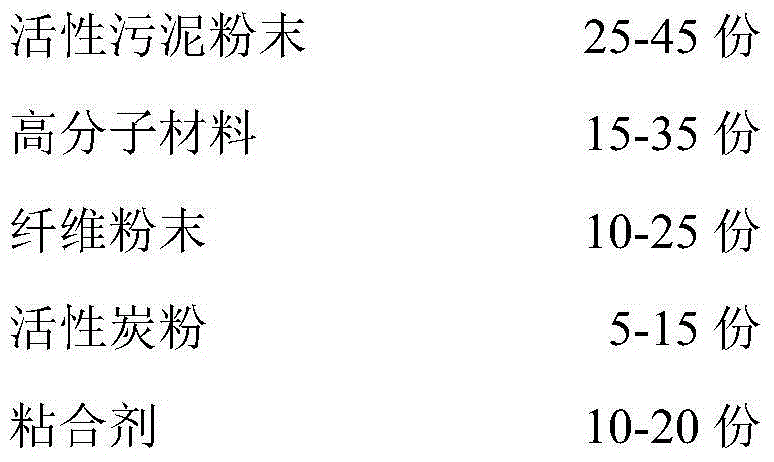

[0035] First, add each component material into the high-speed mixer according to the following proportions by weight, heat and stir, and stir evenly after 2 hours;

[0036]

[0037] Auxiliaries: including sodium stearate, coupling agent and compatibilizer, wherein, sodium stearate is 2% of the mass of activated carbon powder; coupling agent is 1% of the mass of activated carbon powder; compatibilizer is 3% of the total mass %.

[0038] Then, the mixture obtained in step 1) is plasticized and extruded through a single-screw extruder, granulated and processed through secondary processing, including injection molding, blown film molding, extrusion molding, etc. to obtain biodegradable plastics, ventilated and cooled After drying, the required degradable plastic products can be made.

[0039] The activated sludge powder used should be the sludge powder that has been domesticated by gradient dynamic cultivation and fermented and dried, because it is rich in polyhydroxyalkanoate...

Embodiment 2

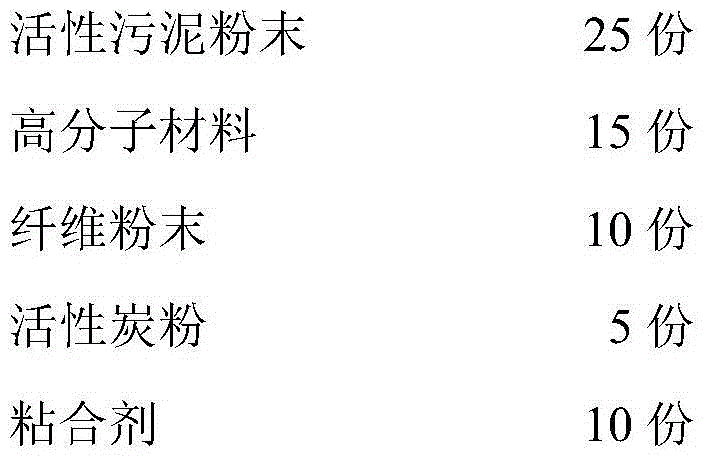

[0053] First, add each component material into the high-speed mixer according to the following proportions by weight, heat and stir, and stir evenly after 2 hours;

[0054]

[0055] Auxiliary agent: comprise sodium stearate, coupling agent and compatibilizer, wherein, sodium stearate is 2% of the quality of activated carbon powder; Coupling agent is 1% of the quality of activated carbon powder; Compatibilizer is the total amount of each component Between 5% of the mass.

[0056] Then, the mixture obtained in step 1) is plasticized and extruded by a single-screw extruder, granulated and processed through secondary processing, that is, injection molding, blown film molding, extrusion molding, etc. to obtain biodegradable plastics, ventilated, cooled and dried After that, the desired degradable plastic products can be made.

[0057] The activated sludge powder used should be the sludge powder that has been domesticated by gradient dynamic cultivation and fermented and dried, ...

Embodiment 3

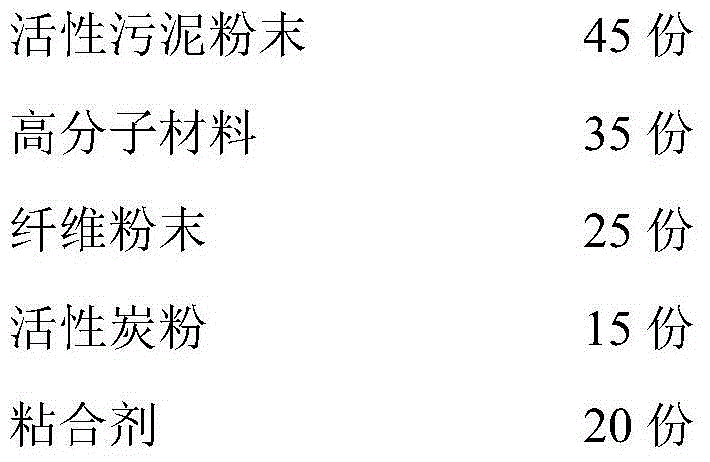

[0071] First, add each component material into the high-speed mixer according to the following proportions by weight, heat and stir, and stir evenly after 2 hours;

[0072]

[0073] Auxiliary agent: comprise sodium stearate, coupling agent and compatibilizer, wherein, sodium stearate is 2% of the quality of activated carbon powder; Coupling agent is 1% of the quality of activated carbon powder; Compatibilizer is the total amount of each component 4% of mass.

[0074] Then, the mixture obtained in step 1) is plasticized and extruded through a single-screw extruder, granulated and processed through secondary processing, including injection molding, blown film molding, extrusion molding, etc. to obtain biodegradable plastics, ventilated, cooled and dried After that, the desired degradable plastic products can be made.

[0075] The activated sludge powder used should be the sludge powder that has been domesticated by gradient dynamic cultivation and fermented and dried, becaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com