Waterborne epoxy modified polyester resin and preparation method thereof

A modified polyester and water-based epoxy technology, applied in the field of coatings, can solve the problems of lack of water-based epoxy modified polyester resin preparation method, poor adhesion of ordinary polyester resin, high VOC content, and achieve good fullness, The effect of high hardness and low VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

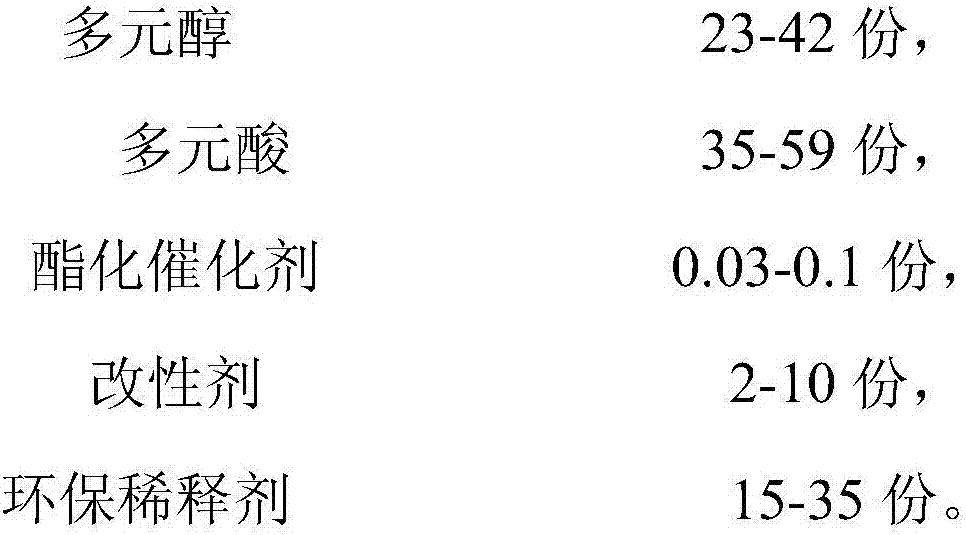

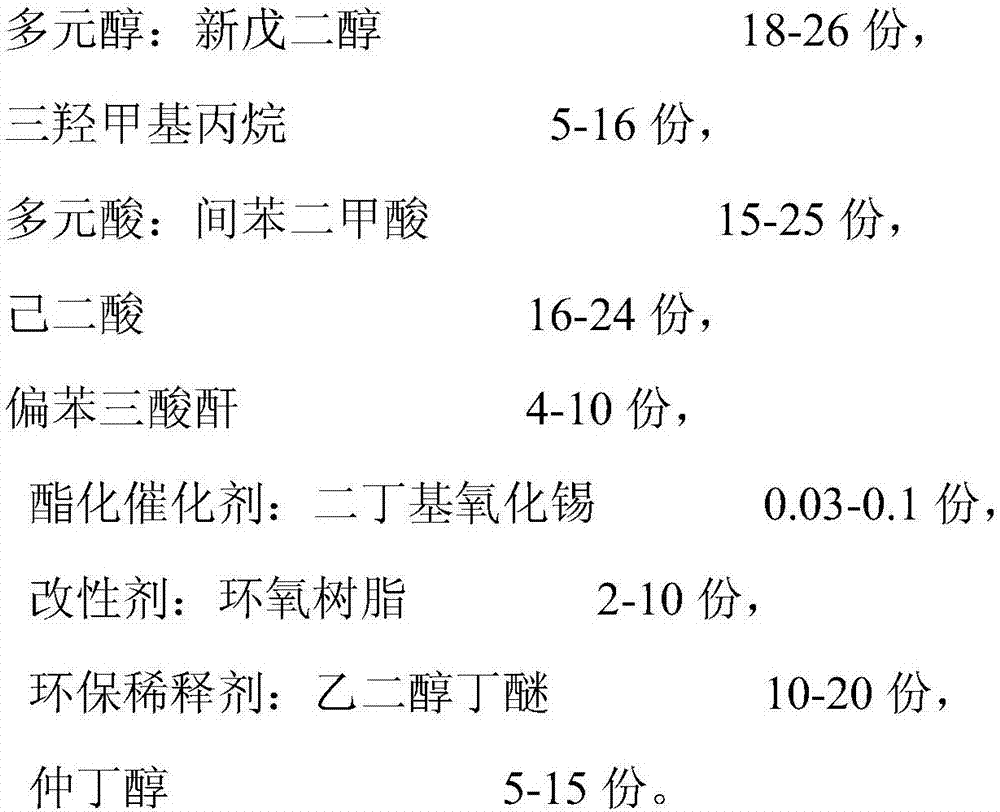

[0030] A kind of waterborne epoxy modified polyester resin of the present invention, described waterborne epoxy modified polyester resin is made up of polyhydric alcohol, polybasic acid, esterification catalyst, modifier, environment-friendly diluent, calculated by weight parts Contains the following components:

[0031]

[0032] The polyhydric alcohol is a combination of two types of neopentyl glycol and trimethylolpropane. The polybasic acid is a combination of two types of isophthalic acid and adipic acid. The epoxy resin is epoxy resin E20; the environmentally friendly diluent is ethylene glycol monobutyl ether. The esterification catalyst is dibutyltin oxide.

[0033] The preparation method of waterborne epoxy-modified polyester resin of the present invention, comprises the steps:

[0034] (1) Weigh each of the components, put the polybasic acid, polyhydric alcohol and esterification catalyst into a reactor filled with nitrogen, slowly heat up to 140°C, start stirri...

Embodiment 2

[0039] The difference between embodiment 2 and embodiment 1 is:

[0040] A kind of waterborne epoxy modified polyester resin of the present invention, described waterborne epoxy modified polyester resin is made up of polyhydric alcohol, polybasic acid, esterification catalyst, modifier, environment-friendly diluent, calculated by weight parts Contains the following components:

[0041]

[0042] Described polyhydric alcohol is neopentyl glycol. The polybasic acid is trimellitic anhydride. The environment-friendly diluent is a combination of four kinds of propylene glycol methyl ether, n-butanol, isopropanol and sec-butanol.

[0043] The preparation method of waterborne epoxy-modified polyester resin of the present invention, comprises the steps:

[0044] In step (1), weigh each of the components, put the polybasic acid, polyhydric alcohol and esterification catalyst into a reactor filled with nitrogen, slowly raise the temperature to 140°C, and start stirring for 10 minut...

Embodiment 3

[0048] The difference between embodiment 3 and embodiment 1 is:

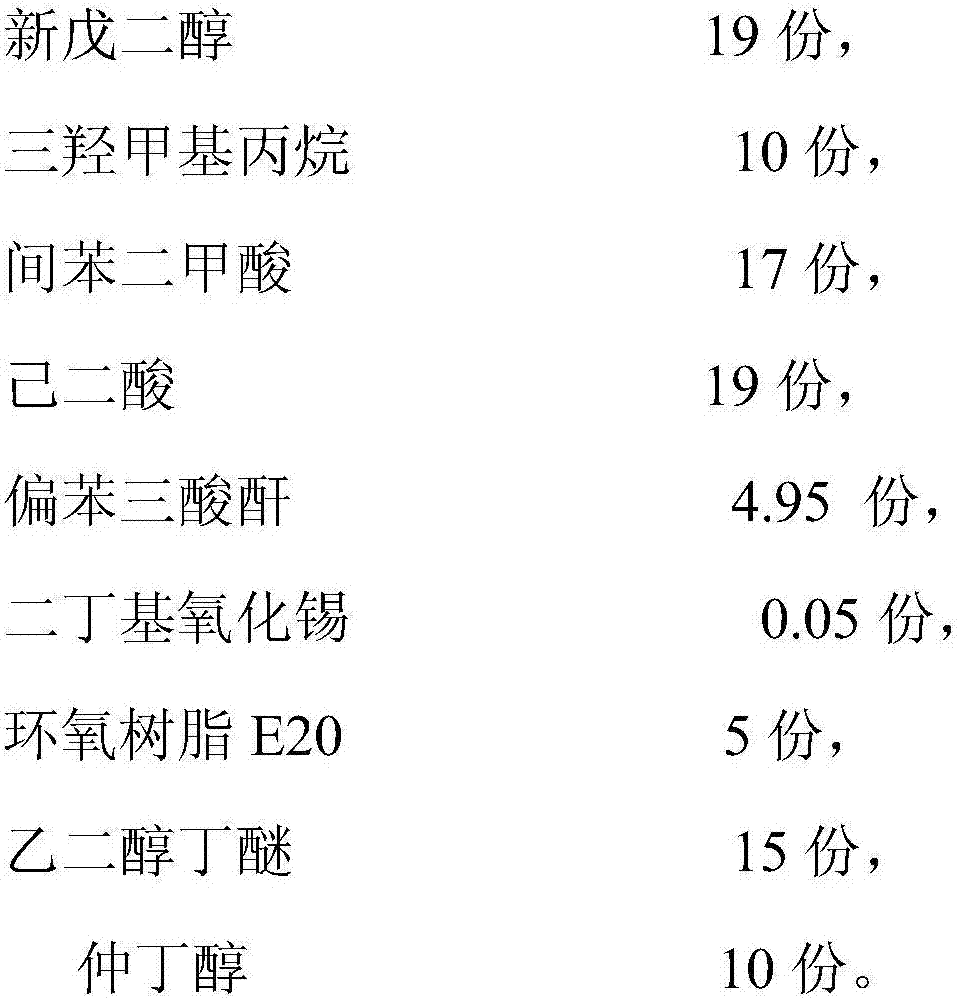

[0049] A kind of waterborne epoxy modified polyester resin of the present invention, described waterborne epoxy modified polyester resin is made up of polyhydric alcohol, polybasic acid, esterification catalyst, modifier, environment-friendly diluent, calculated by weight parts Contains the following components:

[0050]

[0051]

[0052] Described polyhydric alcohol is trimethylol propane. The polybasic acid is a combination of three types of isophthalic acid, adipic acid and trimellitic anhydride. The environmentally friendly diluent is a combination of three of ethylene glycol monobutyl ether, propylene glycol methyl ether and sec-butanol.

[0053] The preparation method of waterborne epoxy-modified polyester resin of the present invention, comprises the steps:

[0054] In step (1), weigh each of the components, put the polybasic acid, polyhydric alcohol and esterification catalyst into a reactor fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com