Flower nutrient soil and preparation method thereof

A kind of technology of flower nutrition soil and production method, applied in the direction of botany equipment and method, culture medium, soilless cultivation, etc., can solve the problems of three kinds of nutrition soil nutrients not lasting, water and soil loss in soil borrowing area, not popularized, etc. , to achieve the effect of reducing secondary pollution, saving costs, and good water and fertilizer retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

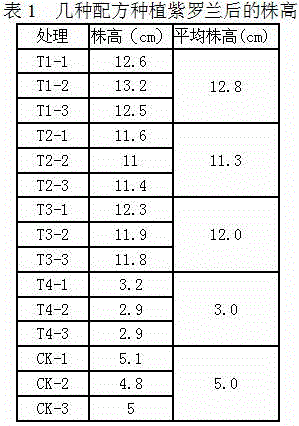

Examples

Embodiment 1

[0023] Embodiment 1: a kind of flower nutrient soil, the percentage by weight of its composition is: bottom mud 40g, volcanic rock 10g, perlite 5g, mushroom slag 20g, sawdust 20g, vermicompost 5g, makes this nutrient soil by above each composition, Its preparation method comprises the following steps:

[0024] (1) Bottom mud production: take the bottom mud from the dredged dump site, use a dryer to dry it, put the dried bottom mud into a crusher for crushing, and then put the crushed bottom mud into a sieving machine for sieving and sieving Machine sieve is the mesh of 2mm, makes bottom mud;

[0025] (2) Put the volcanic rock, perlite, mushroom slag, sawdust and vermicompost into the crusher for crushing and crushing, and the crushed bottom mud enters the sieving machine for sieving, and the mesh of the sieving machine is 2mm;

[0026] (3) Mixing: uniformly mix the bottom mud, volcanic rock, perlite, mushroom slag, sawdust and vermicompost prepared in step (1) and step (2) ac...

Embodiment 2

[0028] Embodiment 2: a kind of flower nutrition soil, the percentage by weight of its composition is: bottom mud 50g, volcanic rock 10g, perlite 5g, mushroom slag 15g, sawdust 15g, vermicompost 5g, make this nutrition soil by above each composition, Its preparation method comprises the following steps:

[0029] (1) Bottom mud production: take the bottom mud from the dredged dump site, use a dryer to dry it, put the dried bottom mud into a crusher for crushing, and then put the crushed bottom mud into a sieving machine for sieving and sieving Machine sieve is the mesh of 2mm, makes bottom mud;

[0030] (2) Put the volcanic rock, perlite, mushroom slag, sawdust and vermicompost into the crusher for crushing, and the crushed bottom mud enters the sieving machine for sieving, and the sieving machine has a mesh of 2 mm;

[0031] (3) Mixing: uniformly mix the bottom mud, volcanic rock, perlite, mushroom slag, sawdust and vermicompost prepared in step (1) and step (2) according to t...

Embodiment 3

[0033] Embodiment 3: a kind of flower nutrient soil, the percentage by weight of its composition is: bottom mud 45g, volcanic rock 10g, perlite 5g, mushroom slag 15g, sawdust 15g, vermicompost 10g, make this nutrient soil by above each composition, Its preparation method comprises the following steps:

[0034] (1) Bottom mud production: take the bottom mud from the dredged dump site, use a dryer to dry it, put the dried bottom mud into a crusher for crushing, and then put the crushed bottom mud into a sieving machine for sieving and sieving Machine sieve is the mesh of 2mm, makes bottom mud;

[0035] (2) Put the volcanic rock, perlite, mushroom slag, sawdust and vermicompost into the crusher for crushing and crushing, and the crushed bottom mud enters the sieving machine for sieving, and the mesh of the sieving machine is 2mm;

[0036] (3) Mixing: uniformly mix the bottom mud, volcanic rock, perlite, mushroom slag, sawdust and vermicompost prepared in step (1) and step (2) ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com