Siphon pump

A siphon tube and pump core technology, applied in the field of siphon tube pumps, can solve the problems of high energy consumption and unfavorable popularization and use, and achieve the effect of low emission and reduced construction and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

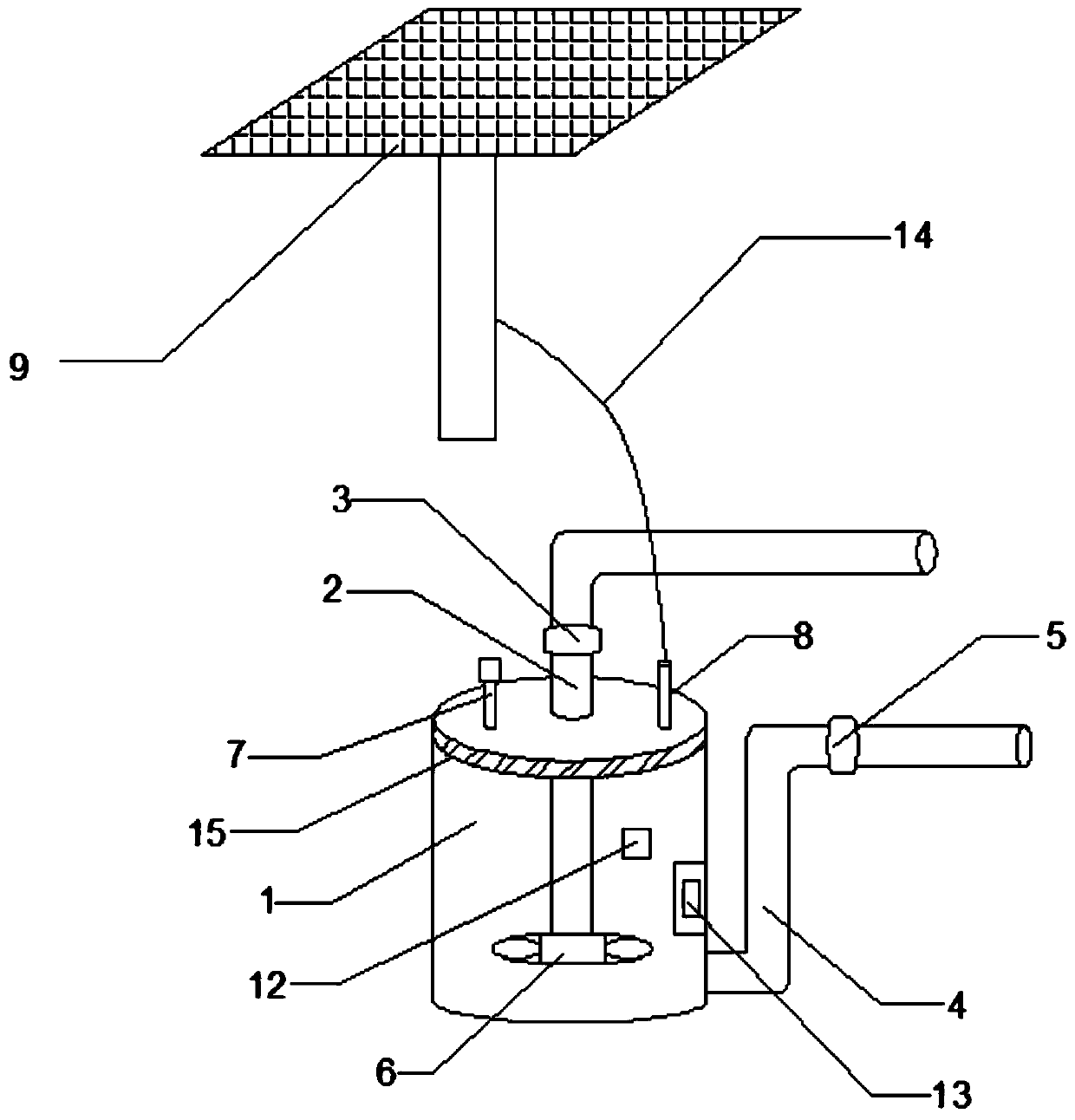

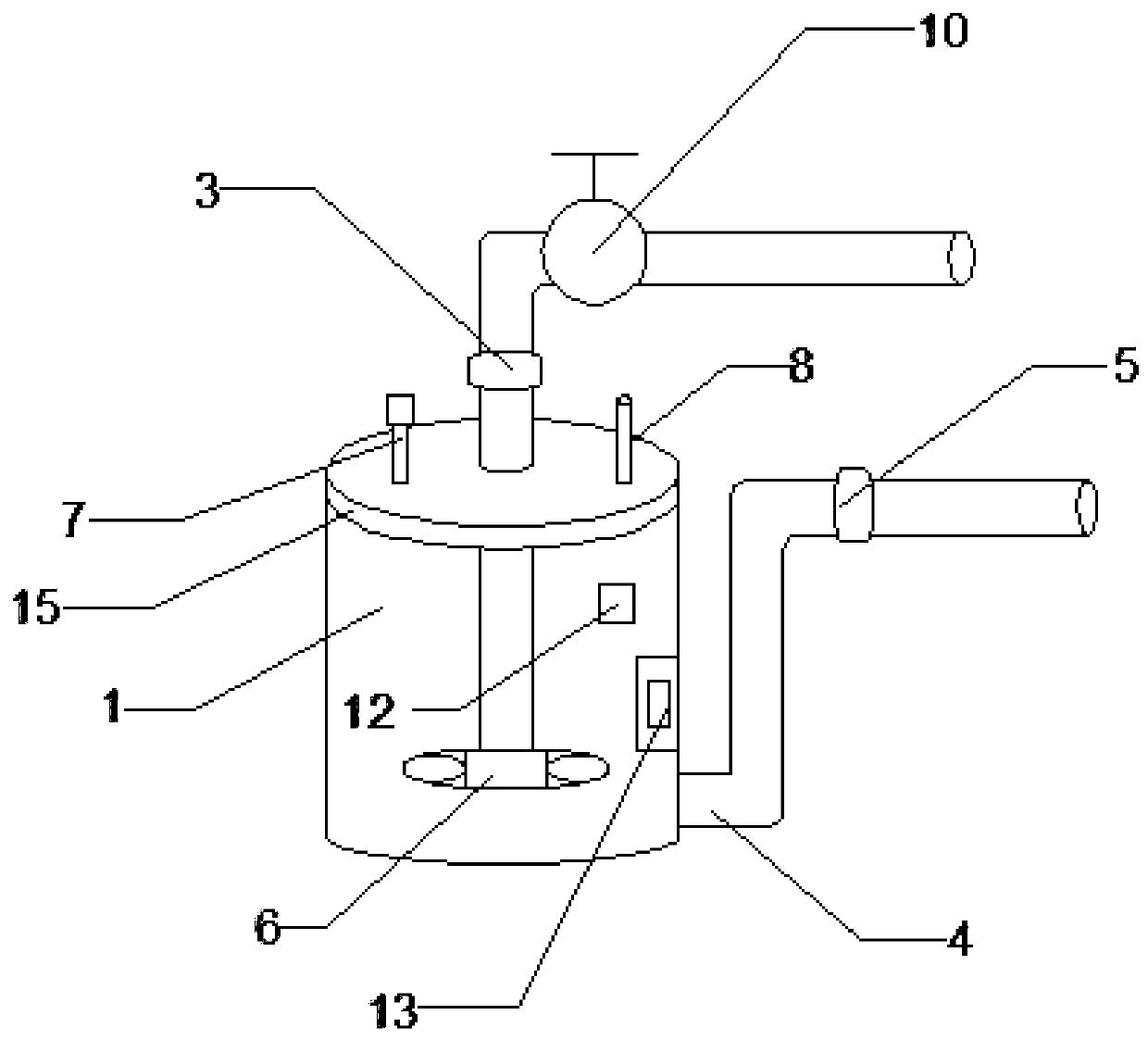

[0019] See figure 1 , A siphon pump comprising an outer tube body 1, a pump core impeller 6, a water level controller 13, a water stop valve 3, a water supplement valve 5, and a water level sensor 12. The outer tube body 1 is a hollow structure, and the outer tube body 1. A water diversion pipe 2 is provided on the top, and the water diversion pipe 2 extends to the inside of the outer tube body 1, a water stop valve 3 is provided on the water diversion pipe 2, and the pump core impeller 6 is arranged at the end of the water diversion pipe 2. The top of the outer tube body 1 is provided with a first exhaust valve 7 which is connected to the exhaust pipe, and the bottom of the outer tube body 1 is provided with a water inlet pipe 4 which extends to the water source Where, the water inlet pipe 4 is provided with a water supply valve 5, the water level sensor 12 and the water level controller 13 are both arranged inside the outer pipe body 1, the water level sensor 12, the water sto...

Embodiment 2

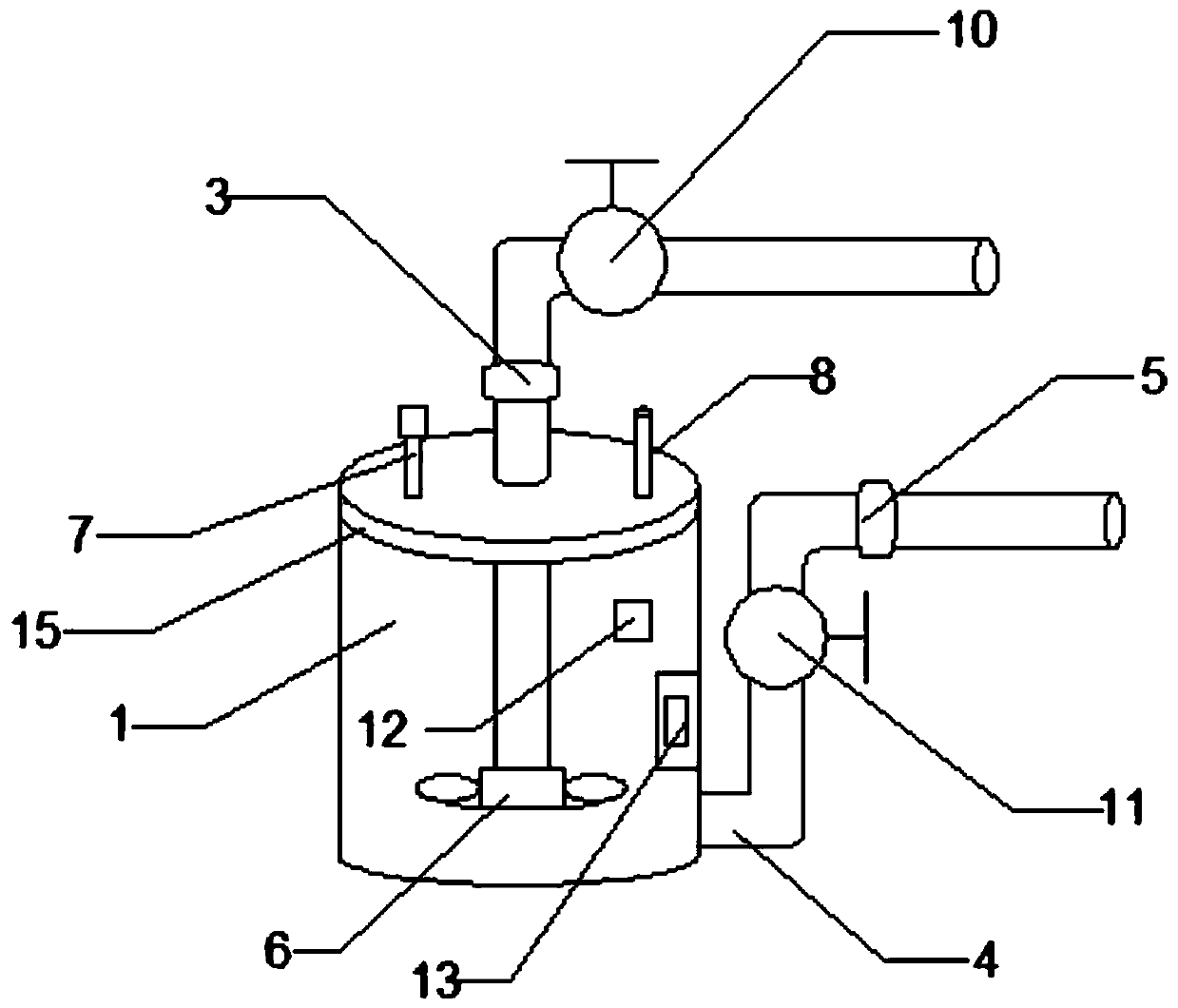

[0027] The difference between this embodiment 2 and embodiment 1 is that a second exhaust valve 10 is provided on the water introduction pipe 2, and the second exhaust valve 10 is provided at the outlet 810 end of the water stop valve 3, and The second exhaust valve 10 is connected to the water pipe 2, and the second exhaust valve 10 is connected to the water level controller 13 via a wire. When the water stop valve 3 needs to be opened, the water level controller 13 preferentially opens the second row The gas valve 10, the second exhaust valve 10 extracts the gas in the water pipe 2 to reduce the gas pressure inside the pipe.

Embodiment 3

[0029] The difference between this embodiment 3 and embodiment 2 is that the water inlet pipe 4 is provided with a third exhaust valve 11, the third exhaust valve 11 is provided at the inlet end of the water make-up valve 5, and the third row The air valve 11 is connected with the water make-up valve 5 and the water inlet pipe 4 in sequence. The third exhaust valve 11 is connected with a signal of the water level controller 13 through a wire. When the water stop valve 3 needs to be opened for water intake, the water level controller 13 is turned on first The third exhaust valve 11 extracts gas from the water inlet pipe 4 and reduces the air pressure in the water inlet pipe 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com