Method for treating complex gold concentrate cyanidation tailings through microwave chloridizing roasting and volatilization

A technology of cyanidation tailings and chlorination roasting, applied in the direction of improving process efficiency, etc., can solve the problems of increasing the risk of secondary pollution of cyanide slag, glass body ring formation, and high organic carbon content, so as to promote the dissociation of monomers and effective reaction area, improving reaction thermodynamics and kinetics conditions, reducing the effect of physical and chemical reaction activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

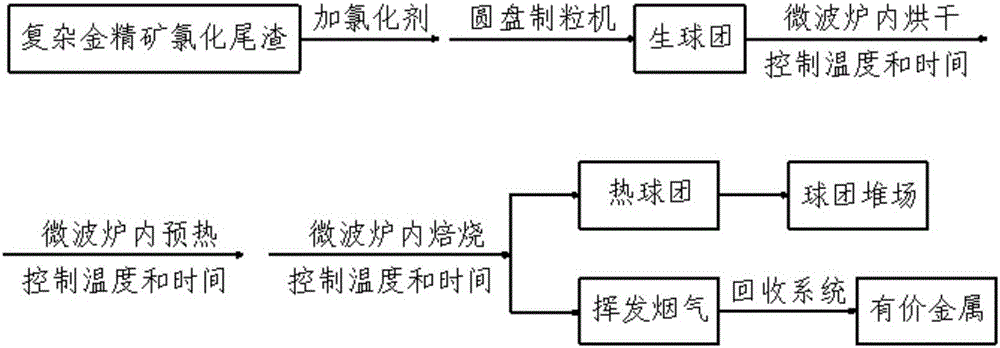

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: a kind of method for processing complex gold concentrate cyanidation tailings with microwave chlorination roasting volatilization, described processing method is carried out according to the following steps: the first step will be equipped with the complex gold concentrate cyanidation tailings of chlorinating agent The slag mixture is sent to the granulator to make pellets to obtain green pellets with a diameter of Φ6~25mm; in the second step, the green pellets obtained in the first step are continuously sent to continuous vertical industrial microwave ovens or continuous horizontal belt industrial In the microwave oven, start the microwave heating device, in which the microwave frequency of the drying section is controlled to 2450MHz, the single-tube power level of the microwave source is 200W, 500W or 1kW, the temperature is controlled at 100°C to 140°C, and the drying time is 30 to 60 minutes; The microwave frequency in the preheating section is controll...

Embodiment 2

[0020] Embodiment 2: a kind of method for processing complex gold concentrate cyanidation tailings with microwave chlorination roasting volatilization, described processing method is carried out according to the following steps: the first step will be furnished with the complex gold concentrate cyanidation tailings of chlorinating agent The slag mixture is sent to the granulator to make pellets to obtain green pellets with a diameter of Φ6~25mm; in the second step, the green pellets obtained in the first step are continuously sent to a continuous vertical industrial microwave oven or a continuous horizontal belt industrial microwave oven , start the microwave heating device, in which the microwave frequency in the drying section is controlled at 915MHz, the single-tube power level of the microwave source is 5kW, the temperature is controlled at 140°C to 160°C, and the drying time is 20 minutes; the microwave frequency in the preheating section is controlled at 915MHz, microwave...

Embodiment 3

[0022] Embodiment 3: a kind of method for processing complex gold concentrate cyanidation tailings with microwave chlorination roasting volatilization, described processing method is carried out according to the following steps: the first step will be furnished with the complex gold concentrate cyanidation tailings of chlorinating agent The slag mixture is sent to the granulator to make pellets to obtain green pellets with a diameter of Φ6~25mm; in the second step, the green pellets obtained in the first step are continuously sent to a continuous vertical industrial microwave oven or a continuous horizontal belt industrial microwave oven , start the microwave heating device, in which the microwave frequency in the drying section is controlled at 915MHz, the single-tube power level of the microwave source is 800W, the temperature is controlled at 180°C to 220°C, and the drying time is 10 to 30 minutes; the microwave frequency in the preheating section is The control is 915MHz, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com