Device and method for extracting vanadium from vanadium slag in suspension state through oxidizing roasting-acid leaching

An oxidative roasting and suspension roasting furnace technology is applied in the fields of mineral processing and metallurgy, which can solve the problems of low vanadium oxidation conversion efficiency, ring formation in rotary kilns, and high energy consumption of sodium roasting, so as to improve equipment production efficiency and avoid high temperature bonding. , the effect of shortening the roasting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The vanadium slag used contains TFe 36.10% by mass percentage, V 2 o 5 12.64%, TiO 2 12.05%, SiO2 15.75%, CaO 1.15%, MgO 3.55%, MnO 2 4.8%, Cr 2 o 3 1.8%;

[0036] (1) The vanadium slag is crushed and ground until the part with a particle size of -0.074mm accounts for 80% of the total mass, and then sieves out the part with a particle size≤0.8mm as vanadium slag powder;

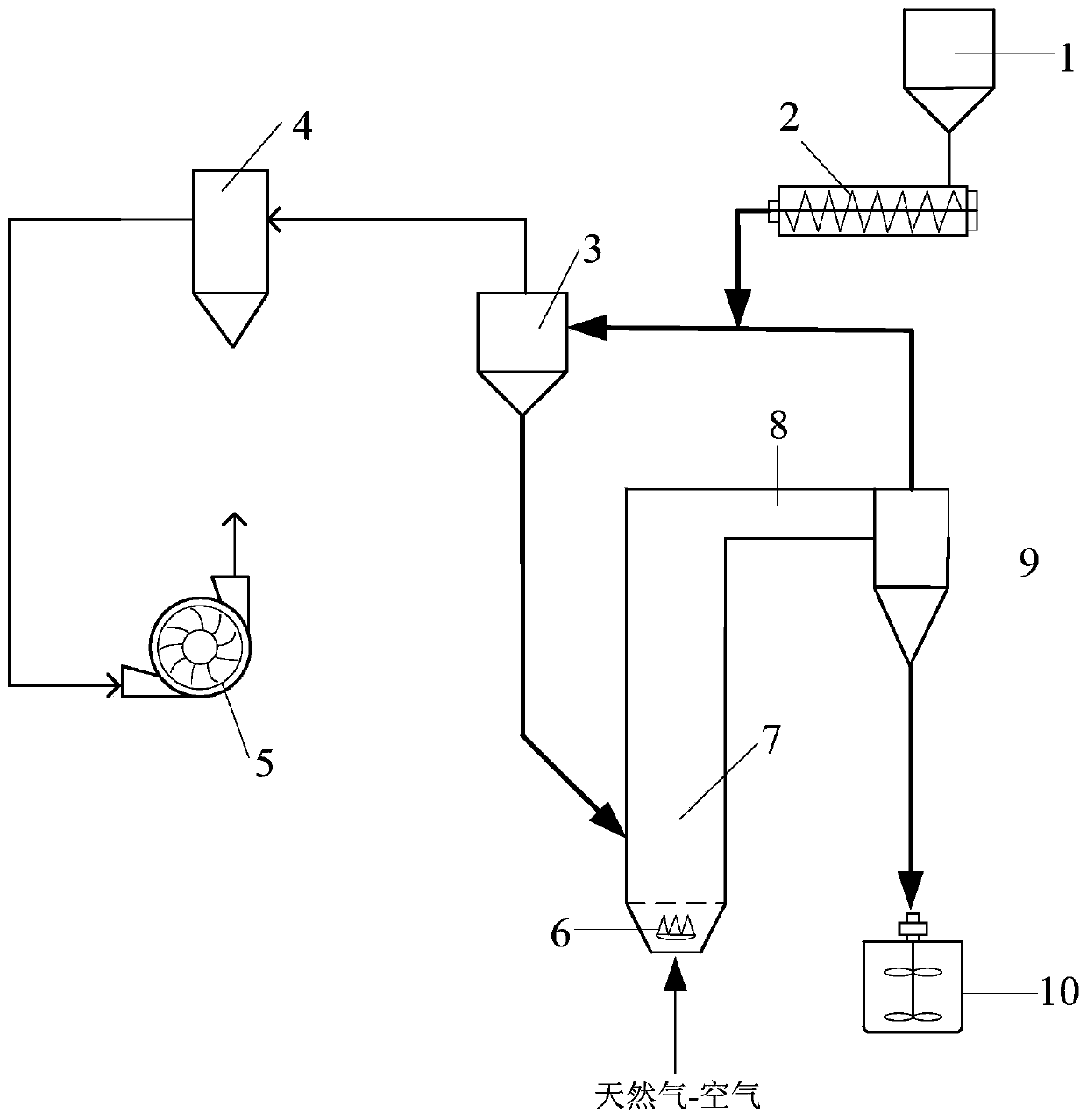

[0037] (2) Vanadium slag powder is placed in the feed bin, and is delivered to the feed inlet pipeline of the first-stage cyclone separator through the screw feeder; Negative pressure is formed in the secondary cyclone separator;

[0038] (3) Under the action of negative pressure, the vanadium slag powder enters the first-stage cyclone separator through the feed inlet pipeline for gas-solid separation, and the first-stage solid material is formed; the first-stage solid material enters the bottom of the suspension roaster;

[0039] (4) Introduce natural gas and air into the burner, and genera...

Embodiment 2

[0043] The vanadium slag used contains TFe 32.63% by mass percentage, V 2 o 5 17.11%, TiO 2 10.83%, SiO 2 14.89%, CaO 1.12%, MgO 2.1%, MnO 2 5.0%, Cr 2 o 3 2.6%.

[0044] Method is with embodiment 1, and difference is:

[0045] (1) The vanadium slag is crushed and ground to a particle size of -0.074mm, accounting for 60% of the total mass;

[0046] (2) The volume flow ratio of natural gas and air passed into the burner is 1:15, and the O in the high-temperature oxidizing gas 2 The volume percentage = 20%, the volume flow rate of the high temperature oxidizing gas in the suspension heating furnace and the mass flow rate ratio of the primary solid material is 4.5m 3 / kg, the temperature in the suspension roaster is 1150°C, the residence time of the primary solid material in the suspension roaster is 40s; 3+ is oxidized to V 5+ The oxidation rate is 93%;

[0047] (3) The initial concentration of the sulfuric acid solution is 180g / L. When stirring and leaching, the ...

Embodiment 3

[0049] The vanadium slag used contains TFe 34.60% by mass percentage, V 2 o 5 15.71%, TiO 2 11.42%, SiO 2 15.77%, CaO 0.99%, MgO 1.9%, MnO 2 6.3%, Cr 2 o 3 3.3%.

[0050] Method is with embodiment 1, and difference is:

[0051] (1) The vanadium slag is crushed and ground to a particle size of -0.074mm, accounting for 65% of the total mass;

[0052] (2) The volume flow ratio of natural gas and air passed into the burner is 1:13, and the O in the high-temperature oxidizing gas 2 The volume percentage = 19%, the volume flow rate of the high temperature oxidizing gas in the suspension heating furnace and the mass flow rate ratio of the primary solid material is 5.3m 3 / kg, the temperature in the suspension roaster is 1200°C, the residence time of the primary solid material in the suspension roaster is 30s; 3+ is oxidized to V 5+ The oxidation rate is 90%;

[0053] (3) The initial concentration of sulfuric acid solution is 150g / L, when stirring and leaching, the liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com