Thin-walled circular type investment casting shell and preparation method thereof

A technology of thin-walled rings and investment molds, which is applied to casting molding equipment, molds, cores, etc., and can solve problems such as low dimensional accuracy, poor surface quality, and casting breakouts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Preparation of the shell of a large thin-walled annular vacuum casting of a certain K4648 superalloy

[0081] 1. The shell composition is as follows:

[0082] (1) Surface layer refractory powder specifications:

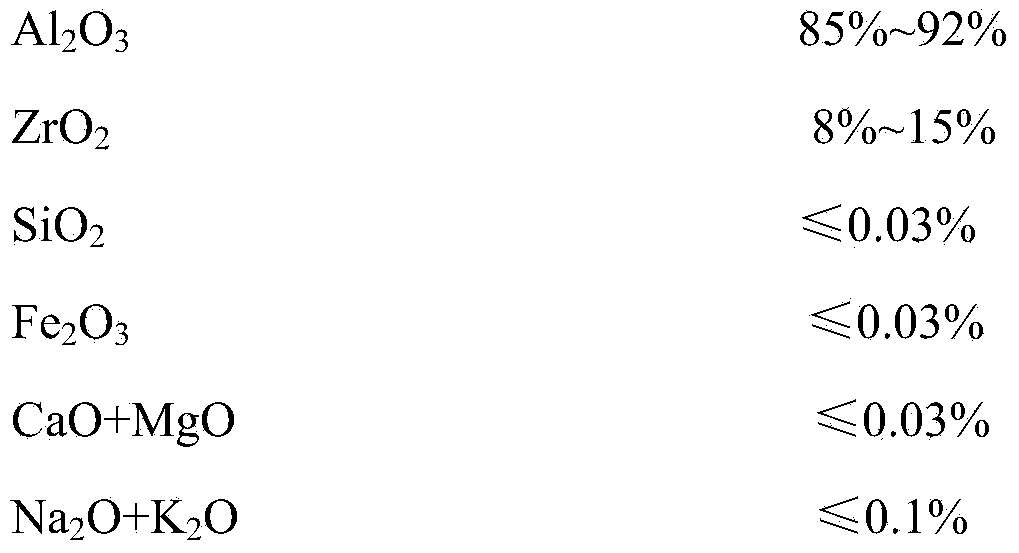

[0083] chemical composition:

[0084]

[0085] Particle size: D95=45-65μm, D50=9-14μm, D10=1-2μm;

[0086] (2) Specifications of the back layer refractory powder:

[0087] chemical composition:

[0088]

[0089] Particle size: D95=45-65μm, D50=10-18μm, D10=1-2.5μm;

[0090] (3) Hanging sand material:

[0091] (3.1) Sand specifications of the first to fourth layers:

[0092] chemical composition:

[0093] Al 2 o 3 ≥99.7%

[0094] Fe 2 o 3 ≤0.09%

[0095] Na 2 O≤0.21%

[0096] Sand size of the first layer: 90-120 mesh,

[0097] Sand size of the second layer: 90-120 mesh,

[0098] Sand size of the third layer: 70-90 mesh,

[0099] Sand size of the fourth layer: 46-70 mesh;

[0100] (3.2) Sand specifications of the 5th t...

Embodiment 2

[0146] Preparation of the shell of a large thin-walled annular vacuum casting of a certain K4169 superalloy

[0147] 1. The shell composition is as follows:

[0148] (1) Surface layer refractory powder specifications:

[0149] chemical composition:

[0150]

[0151] Particle size: D95=45-65μm, D50=9-14μm, D10=1-2μm;

[0152] (2) Specifications of the back layer refractory powder:

[0153] chemical composition:

[0154]

[0155] Particle size: D95=45-65μm, D50=10-18μm, D10=1-2.5μm;

[0156] (3) Hanging sand material:

[0157] (3.1) Sand specifications of the first to fourth layers:

[0158] chemical composition:

[0159] Al 2 o 3 ≥99.7%

[0160] Fe 2 o 3 ≤0.09%

[0161] Na 2 O≤0.21%

[0162] Sand size of the first layer: 90-120 mesh,

[0163] Sand size of the second layer: 90-120 mesh,

[0164] Sand size of the third layer: 70-90 mesh,

[0165] Sand size of the fourth layer: 46-70 mesh;

[0166] (3.2) Sand specifications of the 5th t...

Embodiment 3

[0213] Preparation of the shell of a large thin-walled annular vacuum casting of a certain K438 superalloy

[0214] 1. The shell composition is as follows:

[0215] (1) Surface layer refractory powder specifications:

[0216] chemical composition:

[0217]

[0218] Particle size: D95=45-65μm, D50=9-14μm, D10=1-2μm;

[0219] (2) Specifications of the back layer refractory powder:

[0220] chemical composition:

[0221]

[0222] Particle size: D95=45-65μm, D50=10-18μm, D10=1-2.5μm;

[0223] (3) Hanging sand material:

[0224] (3.1) Sand specifications of the first to fourth layers:

[0225] chemical composition:

[0226] Al 2 o 3 ≥99.7%

[0227] Fe 2 o 3 ≤0.09%

[0228] Na 2 O≤0.21%

[0229] Sand size of the first layer: 90-120 mesh,

[0230] Sand size of the second layer: 90-120 mesh,

[0231] Sand size of the third layer: 70-90 mesh,

[0232] Sand size of the fourth layer: 46-70 mesh;

[0233] (3.2) Sand specifications of the 5th to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com