Preparation method and usage method for foundry silicate binder

A technology of silicate and binder, which is applied in the field of preparation of silicate binder for casting, which can solve the problems of increased water glass addition, accelerated gelation speed, and increased surface tension, and achieves low addition , Improve recycling rate, good collapsibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a method for preparing a silicate binder for casting, comprising the following steps:

[0023] The water glass with a modulus of 1.9-3.0 is spray-dried to obtain a silicate binder for casting, and the solid content of the water glass is 20%-75%.

[0024] In the present invention, the water glass with a modulus of 1.9~3.0 is spray-dried. During the spray-drying process, after the water glass is atomized, the moisture in the water glass is taken away by the high-temperature air flow, and the obtained silicate is hollow and fluffy. Solid powder, which has better instant performance, can be dissolved in water in a short period of time to form water glass. Before use, it is only necessary to dissolve the silicate binder for casting obtained by the present invention in water to prepare the The solution of the required concentration is enough, avoiding the aging phenomenon of water glass in the prior art during use, so that it has good bonding performanc...

Embodiment 1

[0048] Under stirring condition, in the sodium water glass that modulus M is 2.4, add the sodium tripolyphosphate that mass fraction is sodium water glass quality 3.0% and the sodium tetraborate that mass fraction is sodium water glass quality 4.0%, the mixture obtained Heating and dissolving at 95°C to obtain uniform modified water glass, and then spray-drying the obtained modified water glass to obtain modified instant powdery sodium silicate;

[0049] Under the condition of rapid stirring, add the modified instant powdery sodium silicate into an appropriate amount of water at 40°C to dissolve it to form an aqueous solution with a solid content of 45wt%, which can be used after the temperature drops to room temperature.

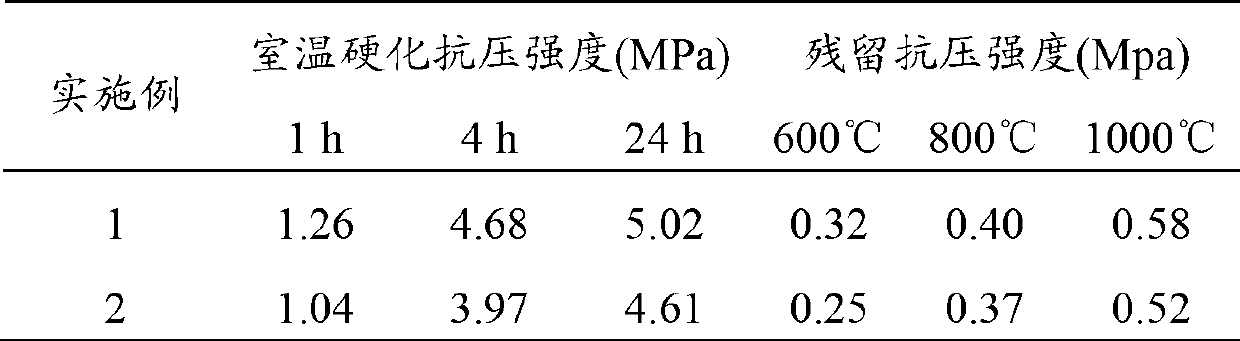

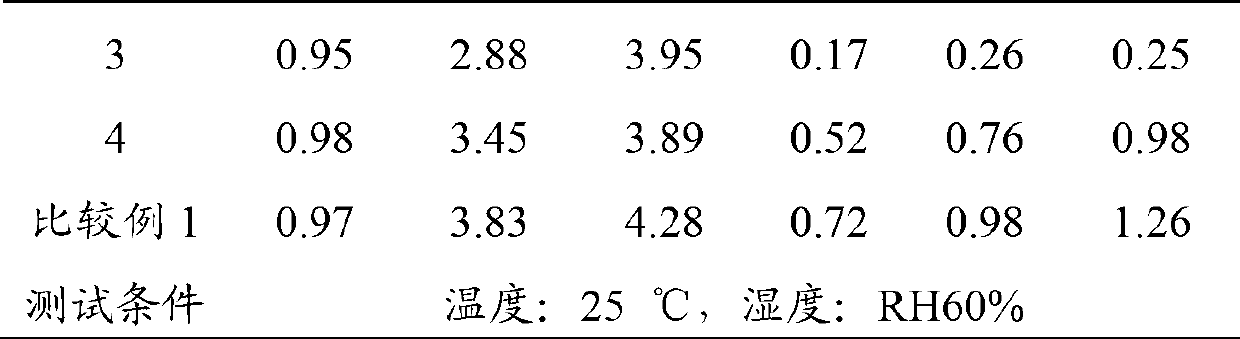

[0050] Add 1000g of standard sand for the detection binder into the SHY blade type sand mixer, add 3.75g of glycerol triacetate to it, mix for 60s, add 25g of the aqueous solution with a solid content of 45wt% obtained in this example, and mix After 60s, th...

Embodiment 2

[0052] Under agitation, add sucrose and sodium water glass and potassium water that account for 4.0% of the total mass of sodium water glass and potassium water glass to sodium water glass and potassium water glass with a modulus M of 2.1 in a weight ratio of 1:1 The total mass of the glass is 0.2% polyacrylamide, and the obtained mixture is heated and dissolved at 70°C to obtain a uniform modified water glass, and then the obtained modified water glass is spray-dried to obtain a modified instant powder silicate .

[0053] Under the condition of rapid stirring, add the modified instant powdered silicate into an appropriate amount of water at 50°C to dissolve it to form an aqueous solution with a solid content of 50wt%, which can be used after the temperature drops to room temperature.

[0054] Put 1000g of standard sand for testing binder into the SHY blade type sand mixer, add 3.3g of triacetin to it, mix for 60s, add 22g of the aqueous solution with a solid content of 50wt% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com