Fast-curing type high-temperature resistant binder and pre-coated sand thereof

A binder and high-temperature-resistant technology, applied in the field of materials, can solve the problems of high cost of refractory particles and environmental pollution, and achieve high strength, simple and easy preparation method, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

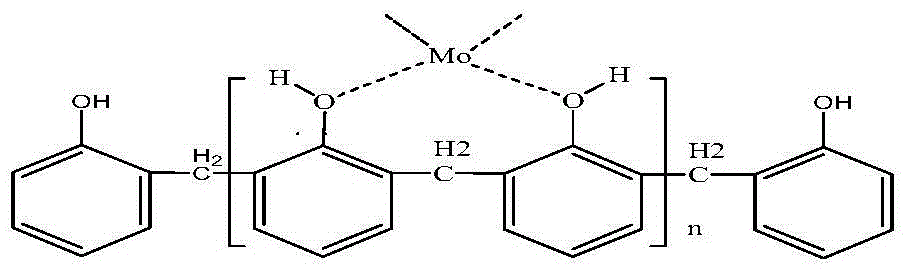

[0044] The preparation of embodiment 1 molybdenum modified high ortho phenolic resin

[0045] (1) Put formaldehyde and phenol into the reactor in a molar ratio of 0.7:1, add a catalyst equivalent to 0.6% of the total mass of phenol at the same time, heat and stir to reflux at 100° C. for 3 hours;

[0046] (2) Cool down to 90°C and add a molybdenum modifier equivalent to 1.5% of the phenol mass, and keep stirring for 40 minutes;

[0047] (3) heating up to 100°C, adding oxalic acid and stirring for 1.2 hours;

[0048] (4) Atmospheric distillation to 130° C. was changed to a vacuum distillation device for vacuum distillation to 180° C. and rapid discharging and cooling to obtain molybdenum-modified high-ortho-position phenolic resin.

[0049]Among them, the catalyst is zinc oxide and zinc acetate with a mass ratio of 1:2, the molybdenum modifier is molybdenum acid, and the amount of oxalic acid is 0.3% of the mass of phenol.

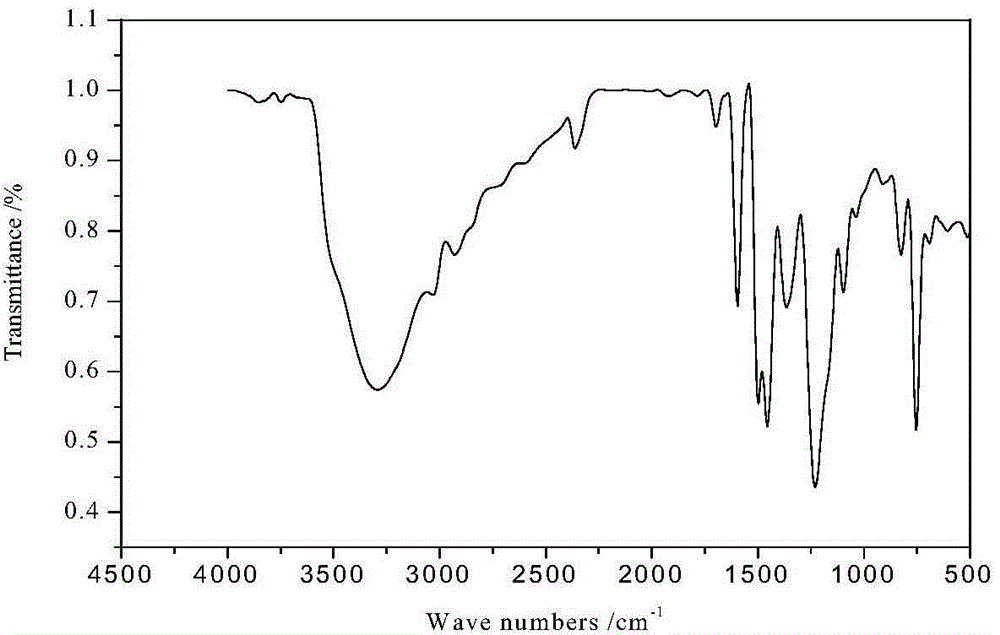

[0050] The infrared analysis diagram of molybdenum ...

Embodiment 2

[0051] The preparation of embodiment 2 molybdenum modified high ortho phenolic resin

[0052] (1) Put formaldehyde and phenol into the reactor in a molar ratio of 0.6:1, add a catalyst equivalent to 0.2% of the total mass of phenol at the same time, heat and stir to 100° C. and reflux for 2.5 hours;

[0053] (2) cooling down to 90 DEG C and adding a molybdenum modifier equivalent to 0.5% of the phenol mass, and insulated and stirred for 30 minutes;

[0054] (3) heating up to 100°C, adding oxalic acid and stirring for 1 hour;

[0055] (4) Atmospheric distillation to 130° C. was changed to a vacuum distillation device for vacuum distillation to 180° C. and rapid discharging and cooling to obtain molybdenum-modified high-ortho-position phenolic resin.

[0056] Among them, the catalyst is zinc oxide and zinc acetate with a mass ratio of 1:2, the molybdenum modifier is molybdenum acid, and the amount of oxalic acid is 0.3% of the mass of phenol.

[0057] The infrared analysis dia...

Embodiment 3

[0058] The preparation of embodiment 3 molybdenum modified high ortho phenolic resin

[0059] (1) Put formaldehyde and phenol into the reactor in a molar ratio of 0.8:1, add a catalyst equivalent to 0.8% of the total mass of phenol at the same time, heat and stir to reflux at 100° C. for 3 hours;

[0060] (2) Cool down to 90°C and add a molybdenum modifier equivalent to 2% of the phenol mass, and keep stirring for 35 minutes;

[0061] (3) heating up to 100°C, adding oxalic acid and stirring for 1 hour;

[0062] (4) Atmospheric distillation to 130° C. was changed to a vacuum distillation device for vacuum distillation to 180° C. and rapid discharging and cooling to obtain molybdenum-modified high-ortho-position phenolic resin.

[0063] Among them, the catalyst is zinc oxide and zinc acetate with a mass ratio of 1:2, and the molybdenum modifier is molybdenum oxalic acid, and the amount of oxalic acid is 0.3% of the mass of phenol.

[0064] The infrared analysis diagram of moly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com