Preparation method of precision-investment casting single-crystal high-temperature alloy thin-wall sample

A technology of investment precision casting and high-temperature alloys, which is applied in casting molding equipment, single crystal growth, single crystal growth, etc., can solve the problems of reduced fluidity, reduced shell collapse, bending and warping, etc. The effect of crystallization occurrence rate, reduction of solidification residual stress, and improvement of fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

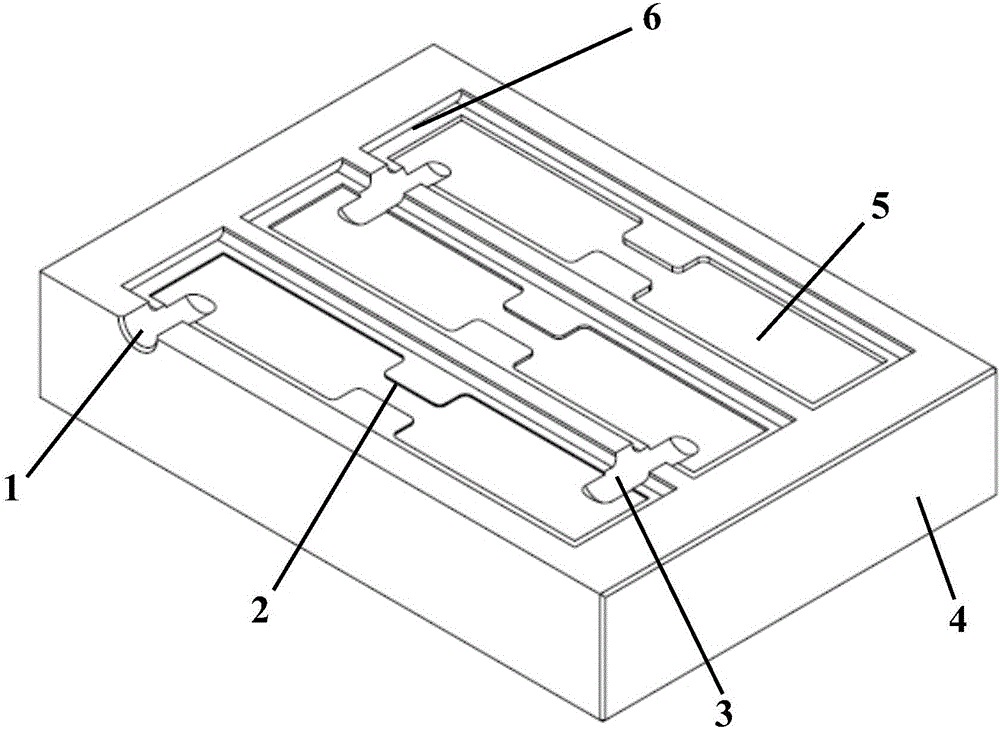

[0016] The preparation process of the invention is core preparation→wax mold pressing→wax mold machining thinning→model shell preparation→directional solidification.

[0017] Using the ceramic core as support, put the plate-shaped ceramic core into the mold, close the mold, inject wax into the mold, and form a certain wax pattern on both sides of the plate-shaped ceramic core to make the wax pattern tight. Attached to the surface of the ceramic core, according to the thickness of the designed thin-walled sample, the wax model of the thin-walled sample is prepared by milling and thinning the wax model. Thin-walled sample wax molds are formed into modules, and then shells are coated to prepare mold shells, and directional solidification casting is completed in a vacuum induction single crystal furnace. Since the ceramic core is used as a support to thin the wax pattern by machining and increase the temperature control during the directional solidification process, the deformatio...

Embodiment 1

[0029] Prepare a plate-shaped ceramic core of 25mm×5mm×150mm, put the core into the ceramic core die of the single crystal superalloy thin-wall sample wax mold pressing mold, close the mold, and align the wax injection port of the mold with the wax pressure Machine injection nozzle, inject wax into the mold, set the wax temperature to 65°C, wax injection pressure 8bar, pressure holding time 70s, and press the wax to the two sides of the plate-shaped ceramic core to make the wax tightly Attached to the surface of the ceramic core.

[0030] Put the pressed wax pattern on the special fixture, according to the thickness of the designed thin-walled sample, use the CNC machine tool to machine and thin the wax pattern, control the spindle speed to 5000r / min, the feed speed to 280mm / min, and the axial The cutting depth is 0.3mm, and the thickness of the wax after thinning is 0.5mm. Trim thinned thin-walled sample wax molds to remove wax chips and burrs generated during machining, and...

Embodiment 2

[0035] Prepare a plate-shaped ceramic core with a size of 25mm×5mm×150mm, put the core into a wax mold of a thin-walled sample of a single crystal superalloy, press the mold, and set the wax temperature at 70°C and the wax injection pressure 5bar, holding time 120s, press the wax to the two sides of the plate-shaped ceramic core, so that the wax is closely attached to the surface of the ceramic core.

[0036] Use CNC machine tools to machine and thin the wax pattern, control the spindle speed to 1000r / min, the feed speed to 45mm / min, and the axial cutting depth to 0.05mm. The thickness of the wax after thinning is 1.5mm. The sample wax models form a group, and the number of sand-hanging layers of the thin-walled sample model shell is 5 layers.

[0037] Directional solidification pouring of single crystal superalloy precision casting thin-walled samples is carried out in a vacuum induction single crystal furnace. The temperature of the upper heater is set to 1540 °C, the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com