Production process of nickel net for high-precision printing

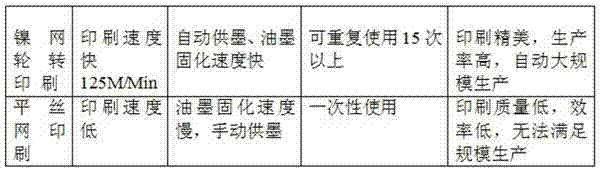

A production process, high-precision technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of unable to meet the mass production of cigarette cartons, slow ink curing, high printing costs, etc., to improve the opening rate of nickel mesh , uniform distribution, improve the smooth effect of printing ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Mold making;

[0030] 1. Customize the mold for laser engraving, the number of molds is 305 mesh, and the processing accuracy of laser engraving is 15 μm.

[0031] 2. Clean the mould, bake evenly in a high-temperature sealed oven at 220°C for 2 hours, and evenly coat the dried mold with 3M metal adhesive;

[0032] 3. Dry again, put the mold into the electroforming tank to electroform the bottom nickel layer, electroplating time is 40 minutes, temperature is 50°C, and conventional electroforming solution is used;

[0033] 4. Adjust the high-temperature oven to 80°C for drying, and apply 3M metal adhesive after the mold is dry;

[0034] 5. Then put the mold into the electroforming tank to electroform the nickel layer. The electroplating time is 40 minutes, the temperature is 50°C, polished and dried, and the mold is spared, using conventional electroforming solution;

[0035] 2. The production of the base network

[0036] 1. Passivate the spare mold, clean it, a...

Embodiment 2

[0043] 1. Mold making;

[0044] 1. Customize the mold for laser engraving, the number of molds is 255 mesh, and the processing accuracy of laser engraving is 15μm.

[0045] 2. Clean the mould, bake evenly in a high-temperature sealed oven at 220°C for 2 hours, and evenly coat the dried mold with 3M metal adhesive;

[0046] 3. Dry again, put the mold into the electroforming tank to electroform the bottom nickel layer, the electroplating time is 35 minutes, and the temperature is 60°C;

[0047] 4. Adjust the high-temperature oven to 80°C for drying, and apply 3M metal adhesive after the mold is dry;

[0048] 5. Then put the mold into the electroformed nickel layer of the double-layer electroforming tank. The upper layer of the double-layer electroforming tank is the electroformed nickel layer, the lower layer is the filter layer, and the upper and lower layers have isolated power supplies. The electroplating time is 45 minutes, and the temperature is 60°C, polished and dried, ...

Embodiment 3

[0057] 1. Mold making;

[0058] 1. Customize the mold for laser engraving, the number of molds is 305 mesh, and the processing accuracy of laser engraving is 15 μm.

[0059] 2. Clean the mould, bake evenly in a high-temperature sealed oven at 220°C for 2 hours, and evenly coat the dried mold with 3M metal adhesive;

[0060] 3. Dry again, put the mold into the electroforming tank to electroform the bottom nickel layer, electroplating time is 45 minutes, temperature is 50°C, and conventional electroforming solution is used;

[0061] 4. Adjust the high-temperature oven to 80°C for drying, and apply 3M metal adhesive after the mold is dry;

[0062] 5. Then put the mold into the electroforming tank to electroform the nickel layer. The electroplating time is 35 minutes, the temperature is 50°C, polished and dried, and the mold is spared, using conventional electroforming solution;

[0063] 2. The production of the base network

[0064] 1. Passivate the spare mold, clean it, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com