Treatment device and method for chemical nickel plating waste liquid

A technology for waste liquid treatment and electroless nickel plating, which is applied in the fields of chemical instruments and methods, metallurgical wastewater treatment, water/sewage multi-stage treatment, etc. It can solve the problem of limited exchangeable ratio of anion resin, difficulty in stable operation, and low treatment efficiency and other problems, to achieve the effect of reducing secondary pollution, low cost, and low operating intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

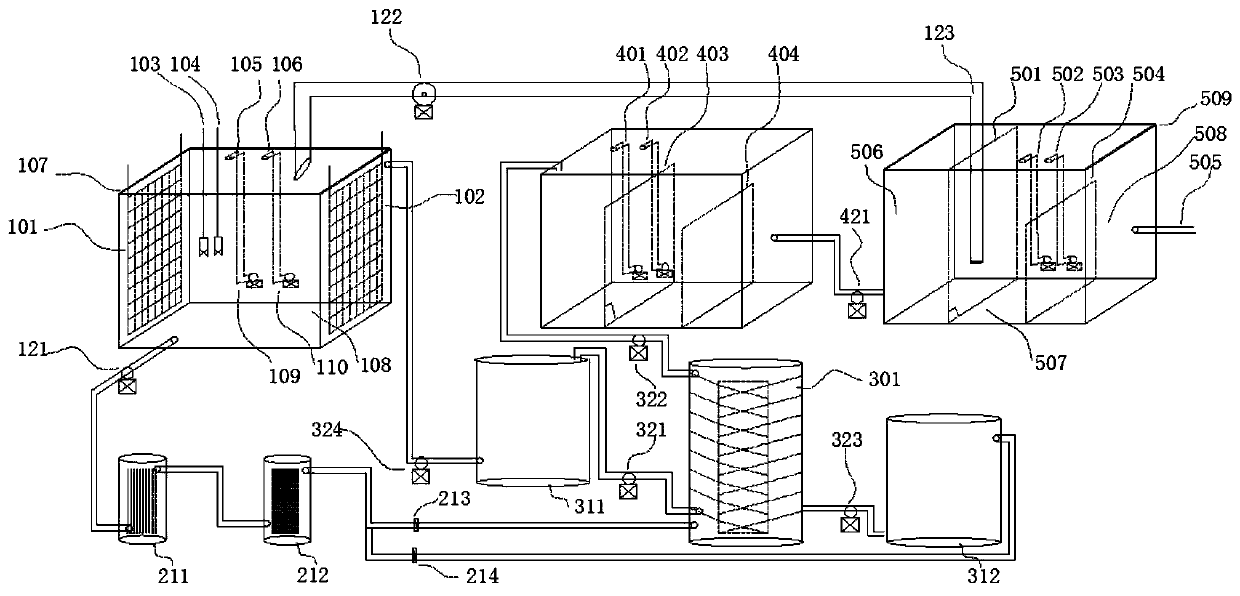

[0058] An electroless nickel plating waste liquid treatment device, which includes an electrolytic catalytic system, a security filter system, a resin adsorption regeneration system, a multi-stage oxidation degradation system and a deep oxidation precipitation system;

[0059] The electrolytic catalytic system includes an electrolytic cell, a dosing control system and an aeration air duct 123; the aeration air duct 123 is provided with a fan 122; the electrolytic cell includes an electrolytic chamber 108, a cathode 101, an anode 102 and a first sealing cover 107; the dosing control system includes a pH meter automatic controller 103, an ORP automatic controller 104, a liquid caustic dosing pump 109 and a sodium chloride dosing pump 110; the liquid caustic dosing pump 109 extends into the In the electrolysis chamber, the sodium chloride dosing pump 110 extends into the electrolysis chamber through the sodium chloride drug inlet 106;

[0060] The security filter system includes ...

Embodiment 2 and 3

[0065] (1) In the electrolytic catalytic system, under electrolytic conditions, the chlorine ions in the chemical nickel waste liquid are oxidized at the anode to generate chlorine gas, and the pH of the solution is controlled to be weakly acidic to slow down the precipitation of chlorine gas, and the dissolved chlorine gas oxidizes phosphite into phosphate At the same time, nickel ions are reduced at the cathode to obtain simple nickel; the chlorine gas produced is injected into the deep oxidation precipitation system through the fan and aeration duct; the solution after electrolysis flows into the security filtration system;

[0066](2) The solution after electrolysis is filtered by cotton core and carbon fiber in the security filtration system in turn, and then under the condition of opening the first valve and closing the second valve, the solution enters the cyclone resin adsorption column for absorption and treatment, and then passes through the third lift pump Enter the ...

Embodiment 2

[0070] Take 10L of chemical nickel waste solution and add it to the electrolytic cell, wherein Ni 2+ Concentration 4.8g / L, NaH 2 PO 4 The concentration is 18.4g / L; initially add 20g of sodium chloride solid into the electrolytic cell; set the DC voltage to 4V; set the pH range to 5-6; set the ORP range to 150-400mV, when the ORP is lower than 400mV, add For sodium chloride solution with a mass concentration of 30%, stop adding sodium chloride after adding 20ml of sodium chloride each time through the quantitative pump control, and monitor the cycle for 5 minutes. If the ORP meter shows higher than 400mV after 5 minutes, stop adding, such as ORP after 5 minutes. When the instrument shows that it is lower than 400mV, continue to add 20ml of sodium chloride to ensure that the potential remains at 150-400mV.

[0071] After electrolysis for 3 hours, sample analysis was carried out. When the nickel ion concentration was 40mg / L, it was pumped into the adsorption column containing 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com