An adsorption device for a detection robot

A technology of adsorption device and robot, which is applied to motor vehicles, transportation and packaging, etc., can solve the problems of hidden dangers of manual safety, large inspection workload, and large energy consumption, and achieve the effect of ensuring the reliability of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the accompanying drawings.

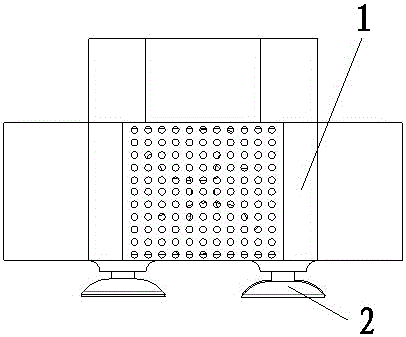

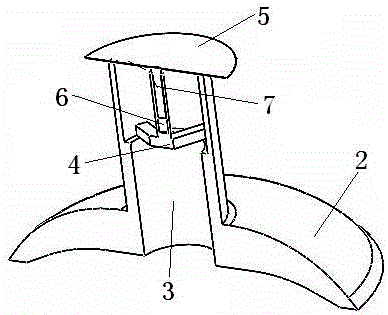

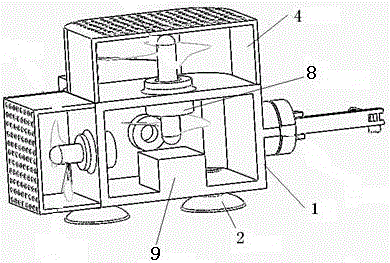

[0016] like figure 1 As shown in the figure, an adsorption device for a detection robot of the present invention includes a robot casing 1, an adsorption suction cup 2, and a control main board 9. The robot casing 1 is provided with a negative pressure cavity, and the negative pressure cavity is inside The top of the cavity is provided with a negative pressure centrifugal fan 8, the negative pressure centrifugal fan 8 is connected with the control main board 9 through a wire, an adsorption suction cup 2 is fixedly installed on the lower surface of the cavity, and the suction suction cup 2 is provided with an exhaust hole 3, A cross fixing frame 4 is arranged in the middle of the exhaust hole 3, and a guide sleeve 6 is fixedly installed on the center upper surface of the cross fixing frame 4. The guide sleeve 6 is sleeved with a sealing disc telescopic shaft 7, so The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com