Cyclone filtering system and dust collector

A filter system and filter technology, which is applied in vacuum cleaners, suction filters, household appliances, etc., can solve the problems of filter sponges with large dust accumulation, small particles, fine ash separation is not optimal, and suction loss is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following description, numerous specific details are set forth in order to provide a thorough understanding of the application. However, the present application can be implemented in many other ways different from those described here, and those skilled in the art can make similar promotions without violating the connotation of the present application. Therefore, the present application is not limited by the specific implementation disclosed below.

[0032] The present application provides a cyclone filtration system to solve the problem that the separation of small particles and fine ash is not optimal in the filtration system in the prior art, resulting in the accumulation of a large amount of dust on the filter sponge downstream of the air flow and the large loss of suction. The application also provides a vacuum cleaner.

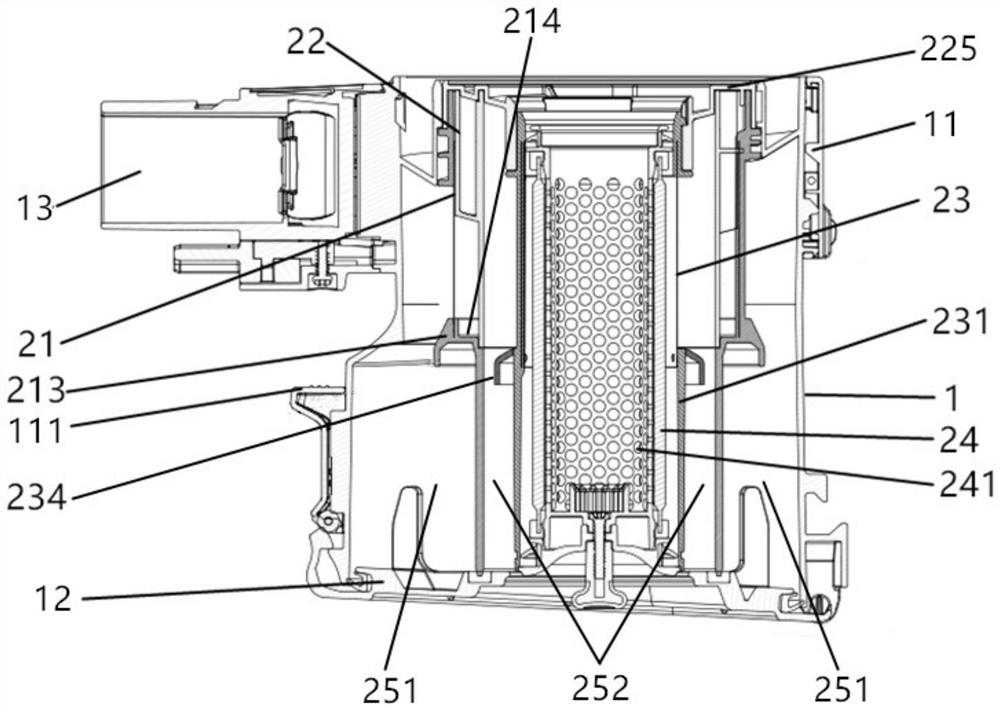

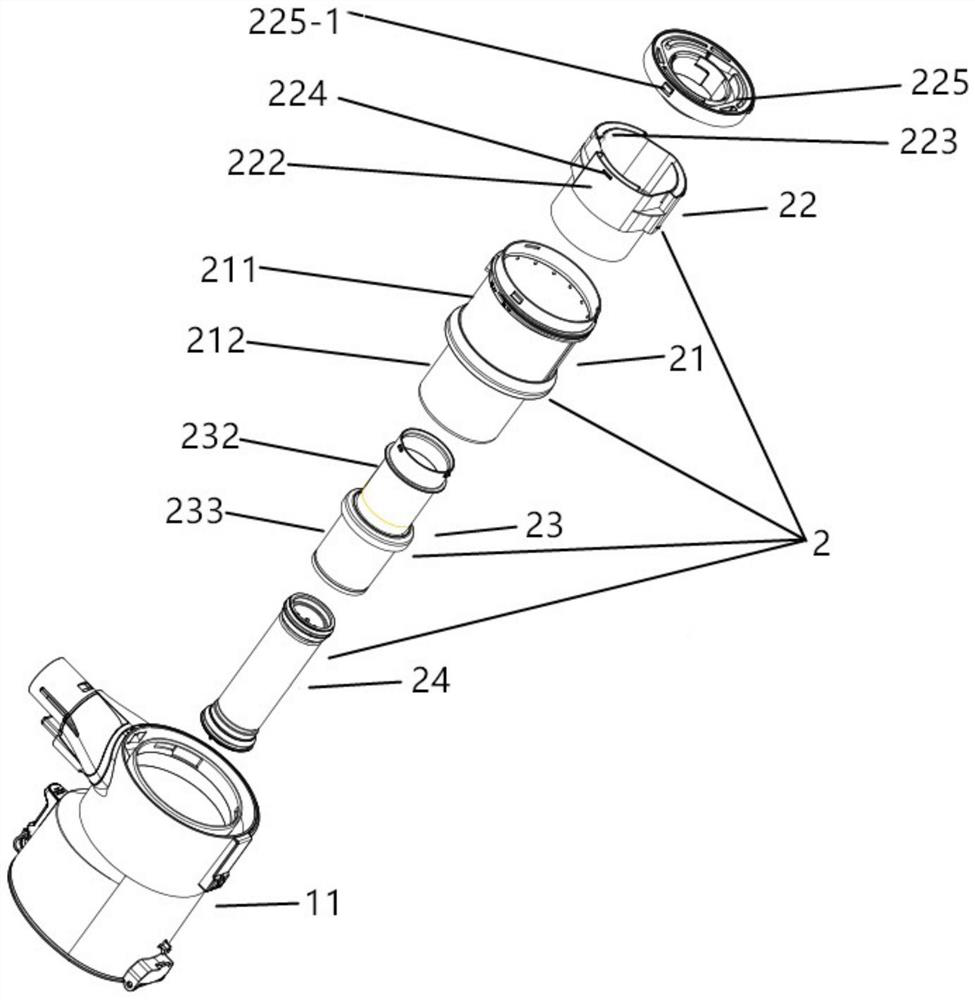

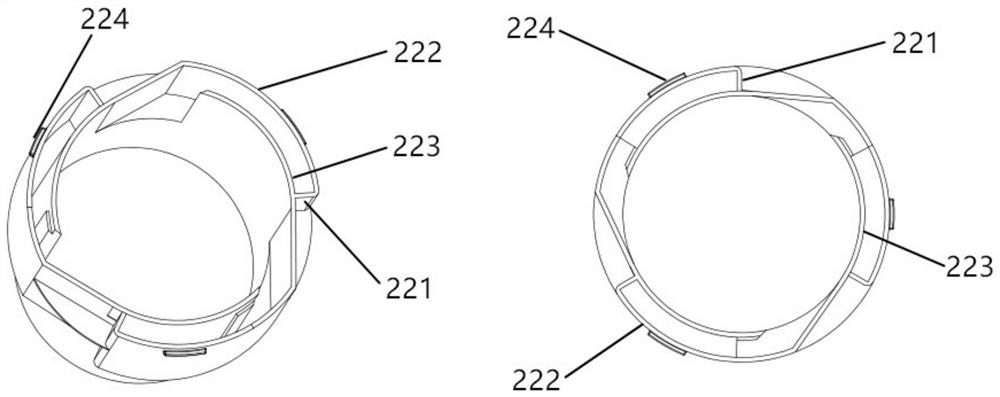

[0033] The application provides a cyclone filter system, including: a dust bucket and a filter device; the dust bucket includes a barrel-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com