Method for manufacturing ultra-oleophobic metal surface with recessed micropores

A metal surface, super oleophobic technology, applied in the field of super oleophobic metal surface preparation, can solve the problems of short service life, no wear resistance, not suitable for large-scale manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

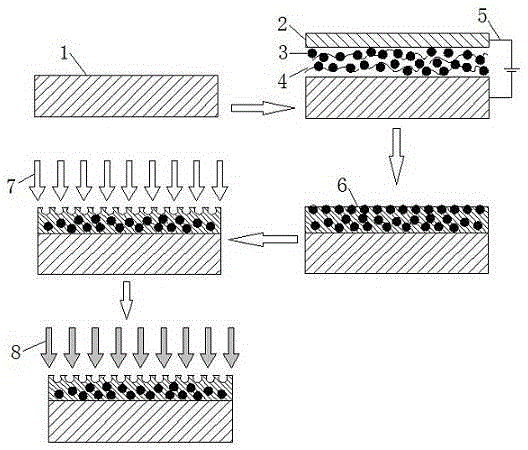

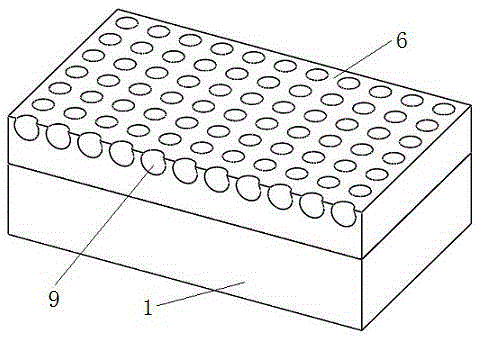

[0020] figure 1 The structure of each stage of the workpiece in the process of the present invention is shown. A method for preparing a super-oleophobic metal surface with concave micropores in the present invention is used to construct a super-oleophobic surface texture on a metal substrate. The preparation method of the super-oleophobic metal surface of concave micropore comprises the following steps:

[0021] S1. Clean and dry the metal base 1 to remove oil and impurities; make the surface of the metal base 1 clean, which is convenient for the subsequent texture component process, so that the texture and the metal base 1 are firmly connected.

[0022] S2. The metal layer on the surface of the metal substrate 1 is electrodeposited, using the nickel block 2 as the anode, and the metal substrate 1 as the cathode. The nickel deposition solution 4 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com