Method for comprehensive utilization of laterite nickel ore

A technology of laterite nickel ore and ammonium bisulfate, which is applied in nickel sulfide, process efficiency improvement, magnesium oxide, etc., and can solve problems such as land occupation and ecological environment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

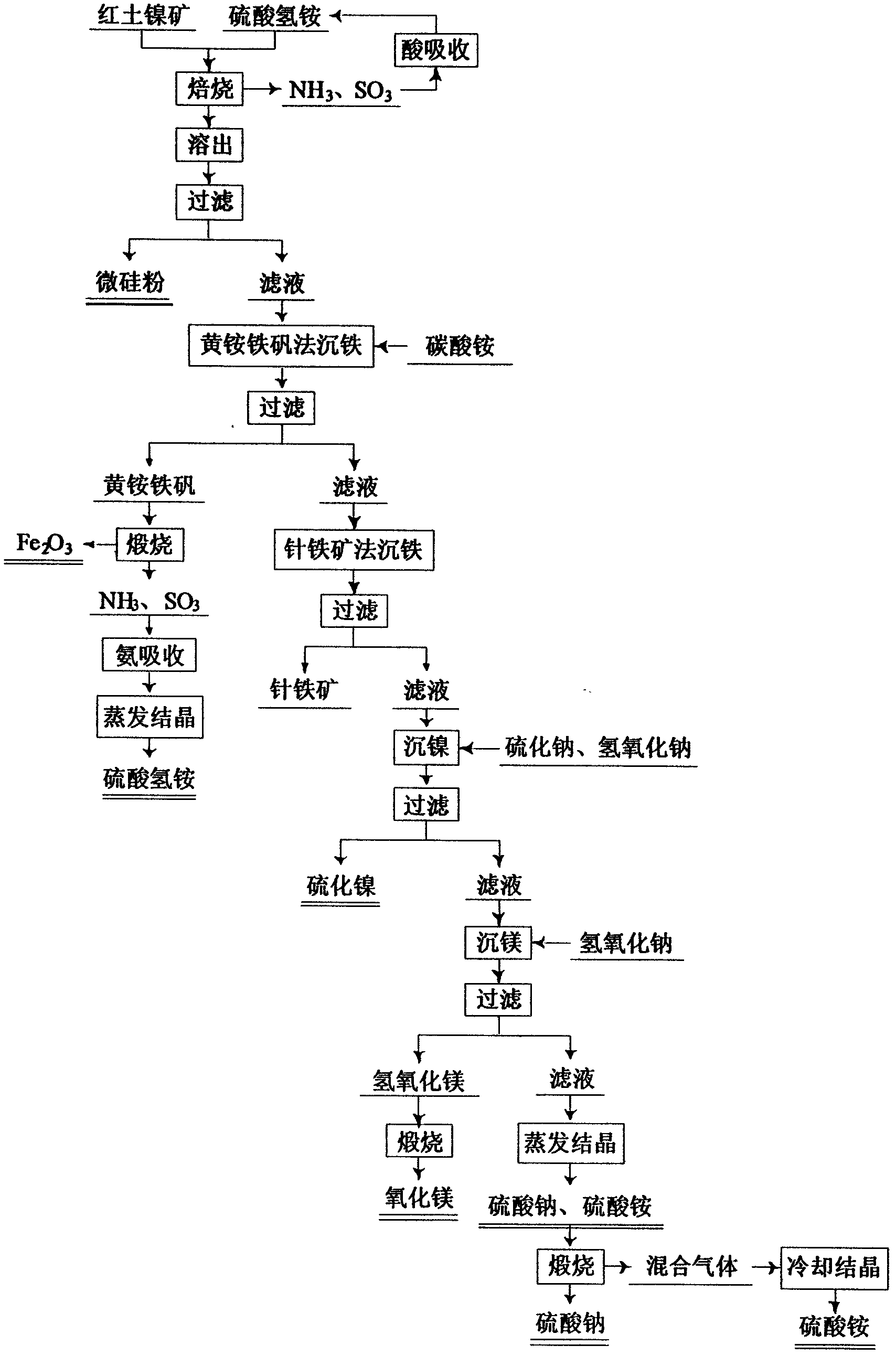

Method used

Image

Examples

Embodiment 1

[0033] The composition of the laterite nickel ore used is: NiO 0.93%, SiO 2 40.74%, MgO 21.53%, Fe 2 o 3 18.82%, Al 2 o 3 4.45%, CaO 0.62%, Cr 2 o 3 0.56%, other 0.72%, loss on ignition 11.63%.

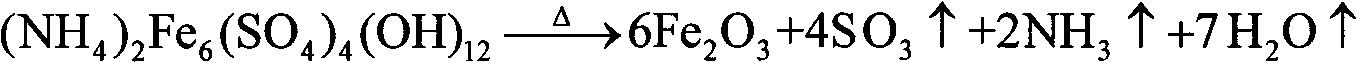

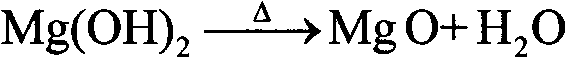

[0034] Crush the laterite nickel ore, grind it to a fineness of less than 80 μm, and mix it with ammonium bisulfate at a mass ratio of 1:1.8. The material is roasted at 350° C. for 4 hours at a constant temperature. The ammonia gas and sulfur trioxide produced during the roasting process are absorbed with dilute sulfuric acid, and the obtained ammonium bisulfate solution is evaporated, concentrated, and crystallized to obtain ammonium bisulfate crystals, which are returned for laterite nickel ore roasting. The roasted clinker was dissolved in 3 times the mass of water at 40°C for 90 minutes, filtered to obtain filtrate and filter residue. The filtrate contains Ni 2+ , Fe 3+ , Fe 2+ , Mg 2+ , NH 4+ , SO 4 2- , the main component of the filter residue is silicon dioxide...

Embodiment 2

[0040] The composition of the laterite nickel ore used is: NiO 1.73%, SiO 2 42.57%, MgO 20.31%, Fe 2 o 3 18.66%, CaO0.68%, Cr 2 o 3 0.52%, other 0.86%, loss on ignition 10.8%.

[0041] The laterite nickel ore is crushed and ground to below 80 μm, mixed evenly with ammonium bisulfate at a mass ratio of 1:2.7, and the material is roasted at 500°C for 1 hour at constant temperature. The ammonia gas and sulfur trioxide produced during the roasting process are absorbed with dilute sulfuric acid, and the obtained ammonium bisulfate solution is evaporated, concentrated, and crystallized to obtain ammonium bisulfate crystals, which are returned for laterite nickel ore roasting. The roasted clinker was dissolved in 3 times the mass of water at 90°C for 30 minutes, filtered to obtain filtrate and filter residue. The filtrate contains Ni 2+ , Fe 3+ , Fe 2+ , Mg 2+ , NH 4 + , SO 4 2- , the main component of the filter residue is silicon dioxide, which is directly used as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com