Method of purifying nickel from chemical nickel-plating waste liquid and nickel purification device

A technology of electroless nickel plating and waste liquid, which is applied in the fields of optics, photographic technology, instruments, etc., can solve the problems of wrong economic and social benefits, low electrolysis efficiency, and large consumption of chemicals, and achieve simplification of process flow and equipment Stable, economical and feasible, no secondary environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

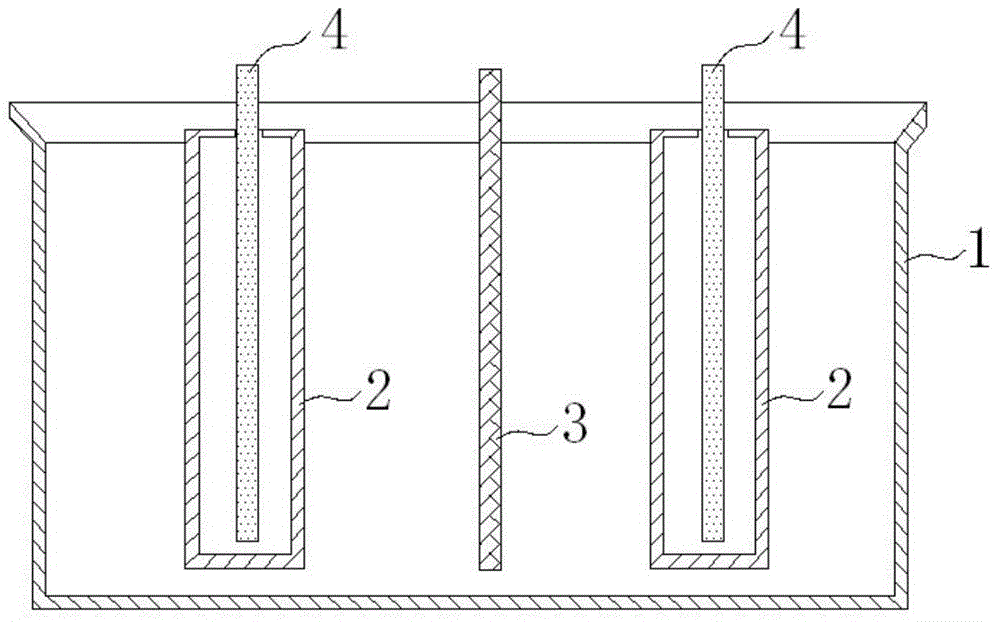

[0028] The electroless nickel plating waste liquid is filtered, and the pH of the electroless nickel plating waste liquid is adjusted to 8 by using a sodium hydroxide solution with a mass fraction of 40-60%. Dilute sulfuric acid solution is contained in the anode box 2 . Then the electroless nickel plating waste liquid is introduced into the cathode chamber 1, so that the liquid level of the electroless nickel plating waste liquid is equal to the liquid level in the anode box 2, and the cathode 3 and the anode 4 are energized to start electrolysis. The voltage of the electrolytic process cell is 2.9V, and the current density of the waste liquid is 100A / m 2 , The temperature is 20 ~ 50 ℃. During the electrolysis process, an appropriate amount of lye is added dropwise to the anode chamber 2 to neutralize the acid produced by the electrolysis reaction, so that the pH value of the solution in the anode chamber 2 remains unchanged. During the electrolysis process, the nickel ion ...

Embodiment 2

[0030] The electroless nickel plating waste liquid is filtered, and the pH of the electroless nickel plating waste liquid is adjusted to 8 by using a sodium hydroxide solution with a mass fraction of 40-60%. Dilute sulfuric acid solution is contained in the anode box 2 . Then the electroless nickel plating waste liquid is introduced into the cathode chamber 1, so that the liquid level of the electroless nickel plating waste liquid is equal to the liquid level in the anode box 2, and the cathode 3 and the anode 4 are energized to start electrolysis. The voltage of the electrolytic process cell is 3V, and the current density of the waste liquid is 200A / m 2 , The temperature is 20 ~ 50 ℃. During the electrolysis process, an appropriate amount of lye is added dropwise to the anode chamber 2 to neutralize the acid produced by the electrolysis reaction, so that the pH value of the solution in the anode chamber 2 remains unchanged. During the electrolysis process, the nickel ion co...

Embodiment 3

[0032] The electroless nickel plating waste liquid is filtered, and the pH of the electroless nickel plating waste liquid is adjusted to 8.5 by using a sodium hydroxide solution with a mass fraction of 40-60%. Dilute sulfuric acid solution is contained in the anode box 2 . Then the electroless nickel plating waste liquid is introduced into the cathode chamber 1, so that the liquid level of the electroless nickel plating waste liquid is equal to the liquid level in the anode box 2, and the cathode 3 and the anode 4 are energized to start electrolysis. The voltage of the electrolytic process cell is 3.5V, and the current density of the waste liquid is 300A / m 2 , The temperature is 20 ~ 50 ℃. During the electrolysis process, an appropriate amount of lye is added dropwise to the anode chamber 2 to neutralize the acid produced by the electrolysis reaction, so that the pH value of the solution in the anode chamber 2 remains unchanged. During the electrolysis process, the nickel io...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com