Environment-friendly chemical nickel deposition solution

An electroless nickel deposition, environment-friendly technology, applied in the field of electroless plating, can solve problems such as environmental impact, achieve the effects of reducing concentration, improving stability, reducing burden and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

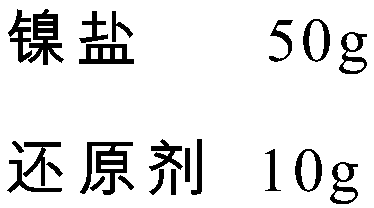

[0043] An environment-friendly chemical nickel deposition solution, every 1 liter of the environment-friendly chemical nickel deposition solution comprises the following components:

[0044] Nickel salt 50g

[0045] Reducing agent 10g

[0046] Complexing agent 5g

[0047] Stabilizer 2.0ppm

[0048] Adjust the pH value of the system to 4.2-5.5 with a buffer,

[0049] The balance is deionized water.

[0050] The nickel salt is nickel sulfate, the reducing agent is sodium hypophosphite, the complexing agent is lactic acid, the stabilizer is antimony potassium tartrate, an appropriate amount of deionized water is added, the pH value of the system is adjusted to 4.2-5.5 with glacial acetic acid, and the Make up to 1 liter.

Embodiment 2

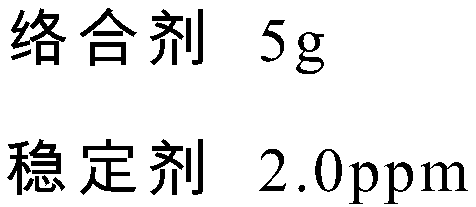

[0052] An environment-friendly chemical nickel deposition solution, every 1 liter of the environment-friendly chemical nickel deposition solution comprises the following components:

[0053] Nickel salt 25g

[0054] Reductant 50g

[0055] Complexing agent 50g

[0056] Stabilizer 1.0ppm

[0057] Adjust the pH value of the system to 4.2-5.5 with a buffer,

[0058] The balance is deionized water.

[0059] The nickel salt is nickel chloride, the reducing agent is sodium hypophosphite, the complexing agent is tartaric acid, the stabilizer is bismuth citrate, an appropriate amount of deionized water is added, the pH value of the system is adjusted to 4.2-5.5 with glacial acetic acid, Make up to 1 liter.

Embodiment 3

[0061] An environment-friendly chemical nickel deposition solution, every 1 liter of the environment-friendly chemical nickel deposition solution comprises the following components:

[0062] Nickel salt 5g

[0063] Reducing agent 5g

[0064] Complexing agent 15g

[0065] Stabilizer 0.5ppm

[0066] Adjust the pH value of the system to 4.2-5.5 with a buffer,

[0067] The balance is deionized water.

[0068] The nickel salt is nickel carbonate, the reducing agent is potassium hypophosphite, the complexing agent is citric acid, the stabilizing agent is bismuth trioxide, an appropriate amount of deionized water is added, and the pH value of the system is adjusted to 4.2 to 5.5 with glacial acetic acid. Water to make up to 1 liter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com