Preparation method of electrochemical alanine biosensor based on boron-doped diamond microelectrode and application thereof

A biosensor, boron-doped technology, applied in the field of electrochemical biosensors, can solve the problems of poor selectivity and sensitivity, difficult surface reconstruction, difficult mass production, etc., achieve good sensitivity and detection range, avoid low stability, The effect of reduced steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

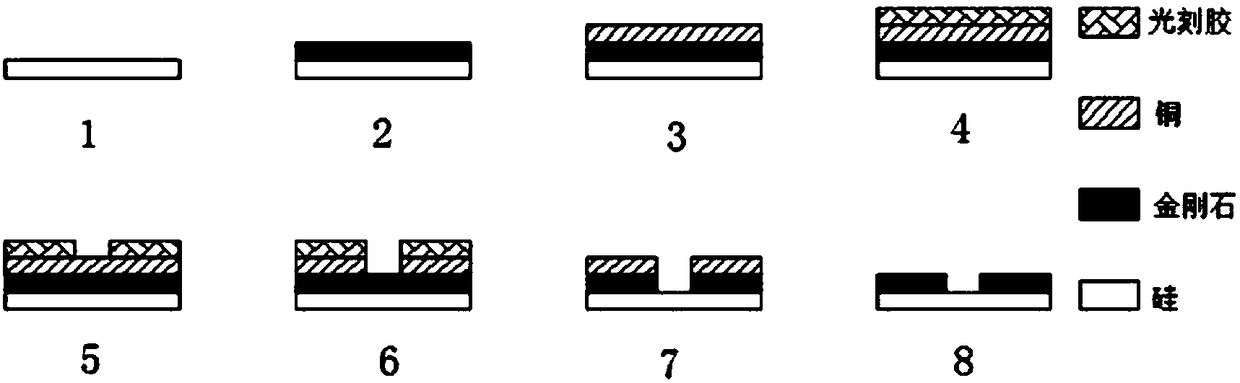

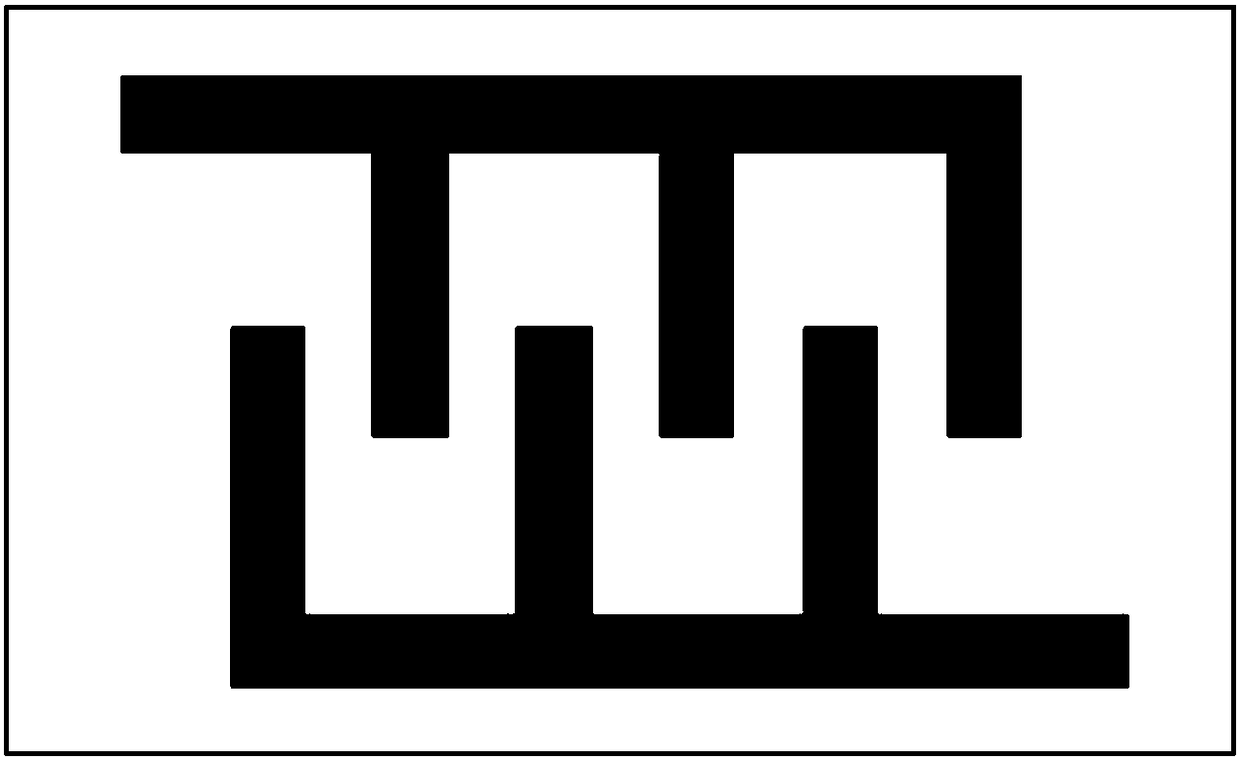

[0029] A method for manufacturing an electrochemical alanine biomicrosensor based on a boron-doped diamond microelectrode, the specific steps are as follows:

[0030] (1) Put the P-type single crystal silicon wafer as the substrate into an acetone solution mixed with diamond micropowder for ultrasonic treatment for 5 minutes, and put it into the acetone solution for ultrasonic cleaning after uniform and dense micro scratches are formed on the surface of the substrate 3min. This process is called pretreatment of the substrate.

[0031] (2) Put the processed P-type single crystal silicon wafer into the hot wire chemical vapor deposition system. The temperature of the hot wire is controlled at 2000-3000°C, the substrate temperature is controlled at 800°C, and the distance between the filament and the substrate is maintained at 4mm. in CH 4 and H 2 nucleation in atmosphere, CH 4 The concentration is 7% (volume fraction), the air pressure is kept at 2kPa, and the nucleation tim...

Embodiment 2

[0038] A method for manufacturing an electrochemical alanine biomicrosensor based on a boron-doped diamond microelectrode, the specific steps are as follows:

[0039] (1) Put the N-type single crystal silicon wafer as the substrate into an acetone solution mixed with diamond powder for ultrasonic treatment for 10 minutes, and after uniform and dense micro scratches are formed on the surface of the substrate, put it into the acetone solution for ultrasonic cleaning for 5 minutes .

[0040] (2) Put the processed N-type single crystal silicon wafer into a microwave plasma chemical vapor deposition system, and control the substrate temperature at 900°C. in CH 4 and H2 nucleation in atmosphere, CH 4 The concentration is 6%, the air pressure is kept at 1kPa, and the nucleation time is controlled at 8min. During the growth process, methane was used as the carbon source and diborane was used as the boron source (B / C=1000ppm), the growth pressure was maintained at 2kPa, and the depo...

Embodiment 3

[0047] A method for manufacturing an electrochemical alanine biomicrosensor based on a boron-doped diamond microelectrode, the specific steps are as follows:

[0048] (1) Put the quartz wafer used as the substrate into an acetone solution mixed with diamond micropowder for ultrasonic treatment for 10 minutes, and after uniform and dense micro-scratches are formed on the surface of the substrate, put it into the acetone solution for ultrasonic cleaning for 4 minutes.

[0049] (2) Put the processed quartz sheet into the DC plasma jet chemical vapor deposition system, the gas ratio is H 2 :Ar:CH 4 =2000:1500:50, the unit is sccm (mL / min). Boron oxide was put into a vacuum chamber for volatilization as a boron source (B / C=4300ppm), and the air pressure was kept at 5kPa. The substrate temperature was 900°C, and the growth time was 3h. After the reaction, a quartz plate with a layer of boron-doped diamond film deposited on the surface was obtained, wherein the thickness of the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com