Electrochemically modified carbon cloth reinforced friction material and preparation method thereof

A friction material and electrochemical technology, applied in the field of friction materials, can solve problems such as harsh conditions and long processing time, and achieve the effects of simple equipment, precise control of the reaction process, and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

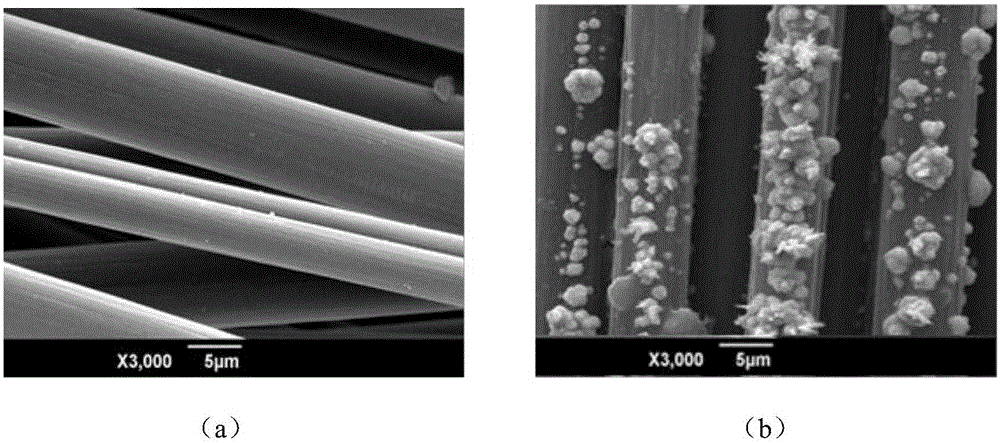

[0031] Step 1: Cut the carbon cloth into a rectangular shape of 7cm*8cm, first soak it in deionized water for 30min, then arrange the carbon cloth in an acetone solution for 12h with ultrasonic assistance, and then dry it to obtain sample P.

[0032] Step 2: nickel sulfate (NiSO 4 ·7H 2 O) 0.1mol / L, ammonium sulfate ((NH 4 ) 2 SO 4 ) 10g / L, boric acid (H 3 BO 4 ) 20g / L, add 500ml of deionized water and stir for 2 hours to obtain composite nickel source electrolyte solution A, the pH at room temperature is controlled to be 2.2-2.7.

[0033] Step 3: Add solution A to the electrolytic cell, fix the sample P on the anode of the graphite electrode, process the current at 2A, and process for 3 minutes. After the reaction is completed, exchange the cathode and anode, and process again for 3 minutes. Remove the carbon cloth from the electrolytic cell Take it out and dry it in an oven at 80°C to obtain sample B.

[0034] Step 4: Put sample B into modified phenolic resin (30% cas...

Embodiment 2

[0037] Step 1: Cut the carbon cloth into a rectangular shape of 7cm*8cm, first soak it in deionized water for 30min, then arrange the carbon cloth in an acetone solution for 12h with ultrasonic assistance, and then dry it to obtain sample P.

[0038] Step 2: nickel sulfate (NiSO 4 ·7H 2 O) 0.05mol / L, ammonium sulfate ((NH 4 ) 2 SO 4 )5g / L, boric acid (H 3 BO 4 ) 10g / L, add 500ml of deionized water and stir for 1 hour to obtain composite nickel sulfate electrolyte solution A, the pH at room temperature is controlled to be 2.2~2.7.

[0039] Step 3: Add solution A into the electrolytic cell, fix the samples P1 and P2 on the cathode and anode of the graphite electrode respectively, the treatment current intensity is 1A, the treatment time is 1min, and the treated carbon cloth is dried in an oven at 60°C Samples B1, B2 were obtained.

[0040] Step 4: spray modified phenolic resin solution (10% nitrile rubber modified phenolic resin dehydrated alcohol solution) on sample B1, ...

Embodiment 3

[0042] Step 1: Cut the carbon cloth into a rectangular shape of 7cm*8cm, first soak it in deionized water for 30min, then arrange the carbon cloth in an acetone solution for 12h with ultrasonic assistance, and then dry it to obtain sample P.

[0043] Step 2: nickel sulfate (NiSO 4 ·7H 2 O) 0.3mol / L, ammonium sulfate ((NH 4 ) 2 SO 4 ) 15g / L, boric acid (H 3 BO 4 ) 30g / L, add 500ml of deionized water and stir for 3 hours to obtain composite nickel sulfate electrolyte solution A, pH control at room temperature is 2.2~2.7.

[0044] Step 3: Add solution A into the electrolytic cell, fix the samples P1 and P2 on the cathode and anode of the graphite electrode respectively, set the treatment current to 3A, and the treatment time to 4min, and dry the treated carbon cloth in an oven at 80°C to obtain Sample B1, B2.

[0045] Step 4: spray modified phenolic resin solution (20% cashew shell modified phenolic resin absolute ethanol solution) on sample B1, B2, dry naturally, get samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com