Peptization solution for metalizing modification of plastic surface

A surface metallization and degumming technology, which is applied in the direction of metal material coating process, liquid chemical plating, coating, etc., can solve the problems of economic loss, incomplete metallization of workpiece surface, plastic leakage, etc., and achieve long service life, Stable production process and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

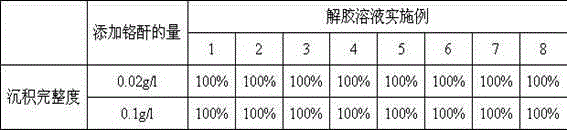

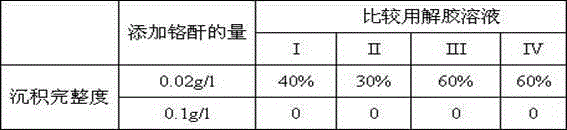

Examples

Embodiment 1

[0021] A degumming solution for metallizing and modifying the surface of plastics. The degumming solution consists of the following components: 100 g / l of sulfuric acid and 5 g / l of hydroxylamine sulfate.

Embodiment 2

[0023] A degumming solution for the metallization modification of plastic surfaces, the degumming solution is composed of the following components: hydrochloric acid 50g / l, sodium fluoride 10g / l, hydrazine hydrochloride 10g / l.

Embodiment 3

[0025] A degumming solution for plastic surface metallization modification, the degumming solution is composed of the following components: fluoroboric acid 60g / l, hydrochloric acid 20g / l, formaldehyde 20g / l, hydroxylamine hydrochloride 2g / l.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com