Device and method for preventing ammonium bisulfate from blocking air preheaters of coal-fired boiler

A technology for air preheaters and coal-fired boilers, which is applied in combustion methods, lighting and heating equipment, and treatment of combustion products. It can solve problems such as air preheater blockage, and achieve the effect of avoiding impact and facilitating normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

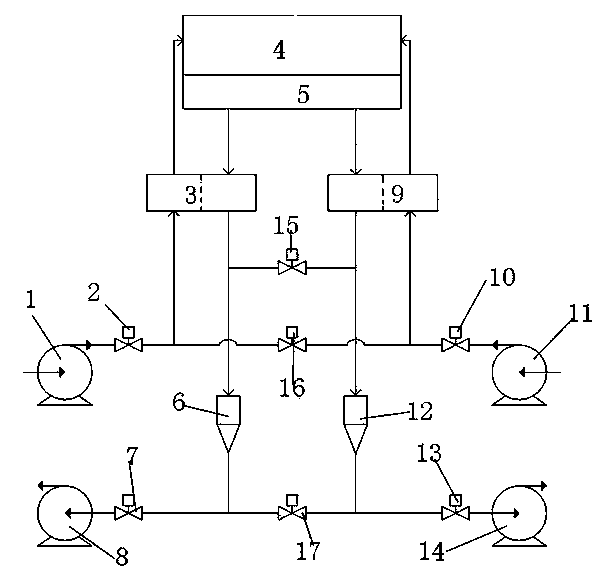

[0020] Such as figure 1 The one shown includes the first air blower 1, the first outlet baffle door 2, the air side of the first air preheater 3, the coal-fired boiler 4, the denitrification device 5, and the flue gas side of the first air preheater 3 connected in sequence , the first dust collector 6, the first inlet baffle door 7 and the first induced draft fan 8, the coal-fired boiler 4 is connected to the air side outlet of the second air preheater 9 at the same time, and the air side of the second air preheater 9 The inlet is connected to the second outlet baffle door 10, the second outlet baffle door 10 is connected to the second blower 11, the flue gas side inlet of the second air preheater 9 is connected to the denitrification device 5, and the flue gas side outlet of the second air preheater 9 The second dust collector 12, the second inlet baffle door 13 and the second induced draft fan 14 are connected in sequence, wherein the first outlet baffle door 2 is connected ...

Embodiment 2

[0023] A coal-fired boiler equipped with SCR flue gas denitrification device in a power plant has a capacity of 300MW, and its structure diagram is as follows figure 1 shown. The sulfur content in the incoming coal of the coal-fired boiler is 1.0%, and the ammonia escape concentration at the outlet of the denitrification device is 2.0mg / m 3 (2.667μmol / mol), the coal-fired boiler adjusts the output of the first induced draft fan 8 and the second induced draft fan 14 and the output of the first blower 1 and the second blower 11, as well as the wind connecting door 16 and the second flue gas connecting door 17 The opening and closing control of the first air preheater 3 increases the mass flow ratio of the flue gas flow at the flue gas side inlet to the air side inlet air to more than 5, so that the temperature at the flue gas side outlet of the first air preheater 3 reaches 280-300 °C for 4 hours. After 24 hours of working time, the working state of the first air preheater 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com