Quaternary ammonium ionic liquid as well as preparation and application method thereof

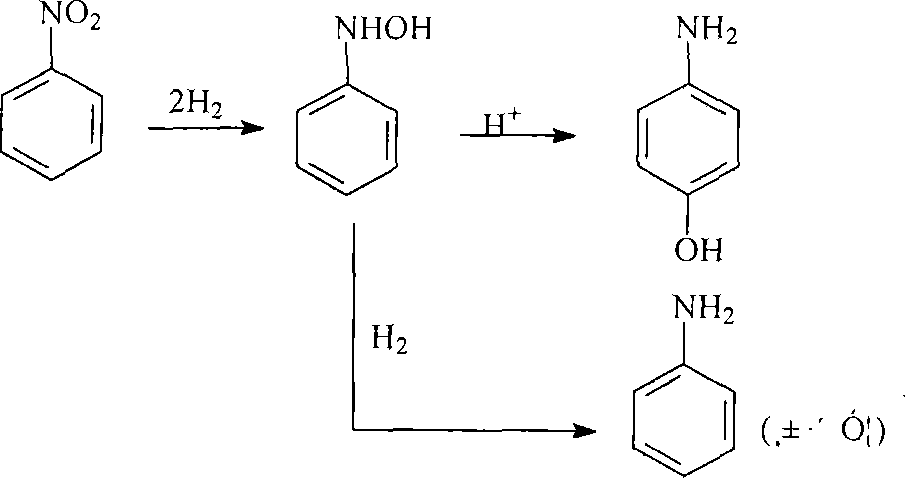

The technology of a quaternary ammonium salt ion and an application method is applied to the quaternary ammonium salt ionic liquid and the fields of preparation and application thereof, which can solve the problems of low yield of aminophenol, harsh reaction conditions, unfriendly environment and the like, and achieves low corrosion and low melting point. , the effect of wide liquid range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

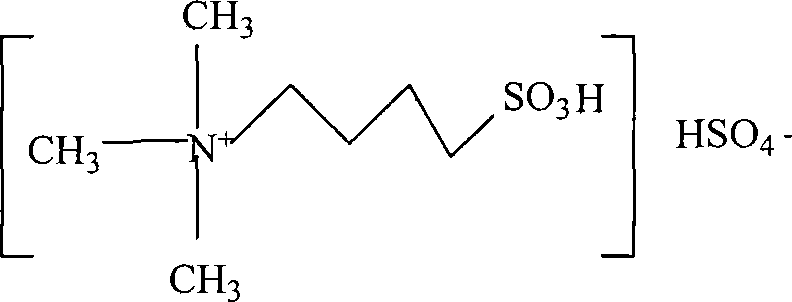

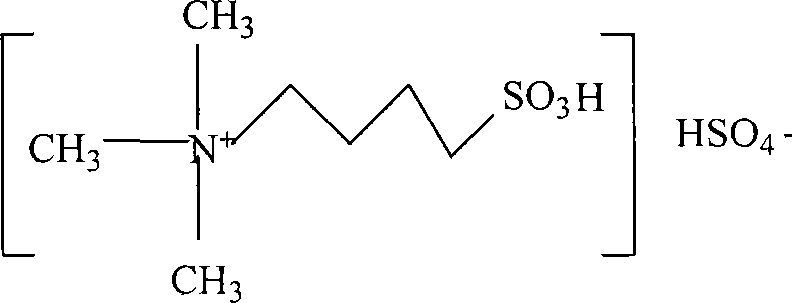

[0036] The first step, the synthesis of N,N,N-trimethyl-N-sulfobutylammonium zwitterion

[0037] Take trimethylamine aqueous solution containing 1.0 mol of trimethylamine and 1.2 mol of 1,4-butane sultone, put them in a 500ml three-necked flask, react at room temperature for 72 hours, take out the reaction solution and depressurize Distilled off water to obtain a white zwitterionic solid, which was washed successively with absolute ethanol, toluene and anhydrous ether, and then vacuum-dried to constant weight at 110°C to obtain a pure zwitterionic solid with a molecular weight of 195.11 ,spare. Wherein the weight content of trimethylamine in the trimethylamine aqueous solution is more than or equal to 33%, and the following examples 2-8 are the same.

[0038] The second step, the synthesis of N, N, N-trimethyl-N-sulfobutyl-ammonium bisulfate ionic liquid

[0039] Take 0.50mol of the N,N,N-trimethyl-N-sulfobutylammonium zwitterion prepared in the first step and put it into a ...

Embodiment 2

[0041] The first step, the synthesis of N,N,N-trimethyl-N-sulfobutylammonium zwitterion

[0042] Take trimethylamine aqueous solution containing 1.0 mol of trimethylamine and 0.8 mol of 1,4-butane sultone, put them in a 500ml three-neck flask, react at 70°C for 8 hours, take out the reaction solution and then depressurize Water was distilled off to obtain a white zwitterionic solid, which was washed sequentially with absolute ethanol, toluene and anhydrous ether, and then vacuum-dried at 110°C to constant weight to obtain a pure zwitterionic solid with a molecular weight of 195.11. spare.

[0043] The second step is the same as in Example 1, and N, N, N-trimethyl-N-sulfobutyl-ammonium bisulfate ionic liquid is obtained, and the measurement result is exactly the same as that in Example 1.

Embodiment 3

[0045] The first step, the synthesis of N,N,N-trimethyl-N-sulfobutylammonium zwitterion

[0046] Take trimethylamine aqueous solution containing 1.0 mol of trimethylamine and 0.8 mol of 1,4-butane sultone, put them in a 500ml three-neck flask, react at room temperature for 24 hours, take out the reaction solution and depressurize Water was distilled off to obtain a white zwitterionic solid, which was washed sequentially with absolute ethanol, toluene and anhydrous ether, and then vacuum-dried to constant weight at 50°C to obtain a pure zwitterionic solid with a molecular weight of 195.11. spare.

[0047] The second step, the synthesis of N, N, N-trimethyl-N-sulfobutyl-ammonium bisulfate ionic liquid

[0048] Take 0.50 mol of the N,N,N-trimethyl-N-sulfobutylammonium zwitterion prepared in the first step and put it into a four-necked flask, slowly add 0.35 mol of concentrated sulfuric acid dropwise, and keep the temperature during the dropwise addition Not exceeding 10°C, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com