Method for preparing polynorborene by alkene polymerization catalytic

A polynorbornene, catalytic preparation technology, applied in the chemical industry, can solve the problems of low polymer molecular weight, insoluble polymer, low catalytic activity, etc., and achieve high molecular weight, high glass transition temperature, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

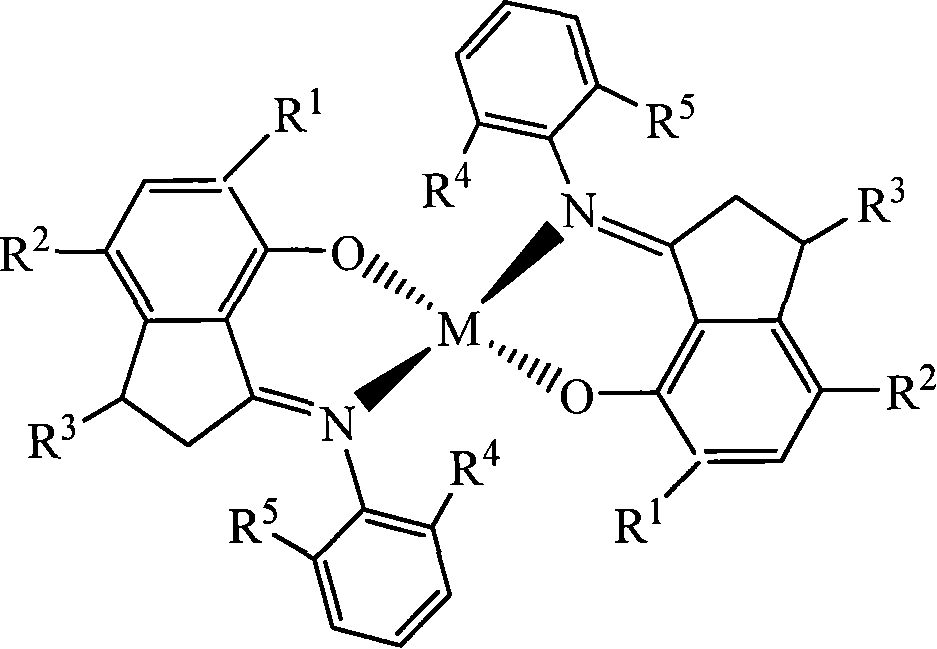

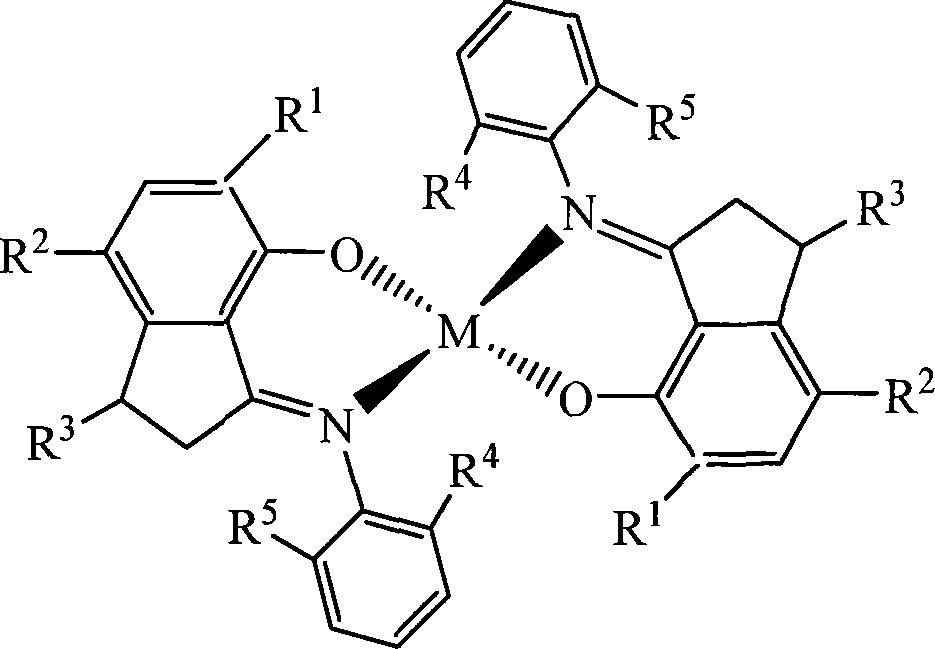

Image

Examples

Embodiment 1

[0020] Example 1 Preparation of Ligand 7-hydroxy-3,4-dimethylindan-1-(N-phenylimine)

[0021] in N 2 2.0g (11.4mmol) 7-hydroxy-3,4-dimethylindanone and 1.4mL (15.0mmol) aniline were added to a 100mL three-necked flask, then 30mL absolute ethanol, 0.1mL formic acid, 0.7 g 4A molecular sieve. Heat to reflux for 48 hours. After the end of the reaction, filter, collect the filtrate, and use anhydrous Mg 2 SO 4 It was dried, concentrated, and passed through a silica gel column with a mixed solution of petroleum ether and ethyl acetate as an eluent to obtain 2.3 g of a yellow solid with a yield of 80%.

Embodiment 2

[0022] Example 2 Preparation of Ligand 7-hydroxy-3,4-dimethyllindan-1-(N-2,6-diisopropylphenylimine)

[0023] in N 21.3mL (11.4mmol) TiCl will be dissolved within 30min 4 30 mL of toluene solution was added to 40 mL of toluene solution containing 8.6 mL (45.4 mmol) of 2,6-diisopropylaniline. The reaction mixture was then heated to 90° C., and 2 g (11.4 mmol) of 7-hydroxy-3,4-dimethylindanone was added after 30 min. At this temperature, the reaction was carried out for 48 hours. After the reaction, the reaction solution was poured into Na 2 CO 3 Saturated aqueous solution, liquid separation, organic phase with anhydrous Mg 2 SO 4 It was dried, concentrated, and passed through a silica gel column using a mixed solution of petroleum ether and ethyl acetate as an eluent to obtain 1.54 g of a red solid with a yield of 40%.

Embodiment 3

[0024] Example 3 Preparation of Olefin Polymerization Catalyst Coordinated with Metal Ni

[0025] 0.122g (0.49mmol) of Ni(OAc) 2 4H 2 O and 0.245g (0.98mmol) of 7-hydroxy-3,4-dimethylindan-1-(N-phenylimine) were added to 20mL of absolute ethanol, and heated to reflux for 5 hours. After cooling, the solid was collected by filtration and dried under vacuum. 0.164 g of a green solid was obtained, yield 60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com