Anti-sulfur film type low-temperature denitration catalyst and preparation method thereof

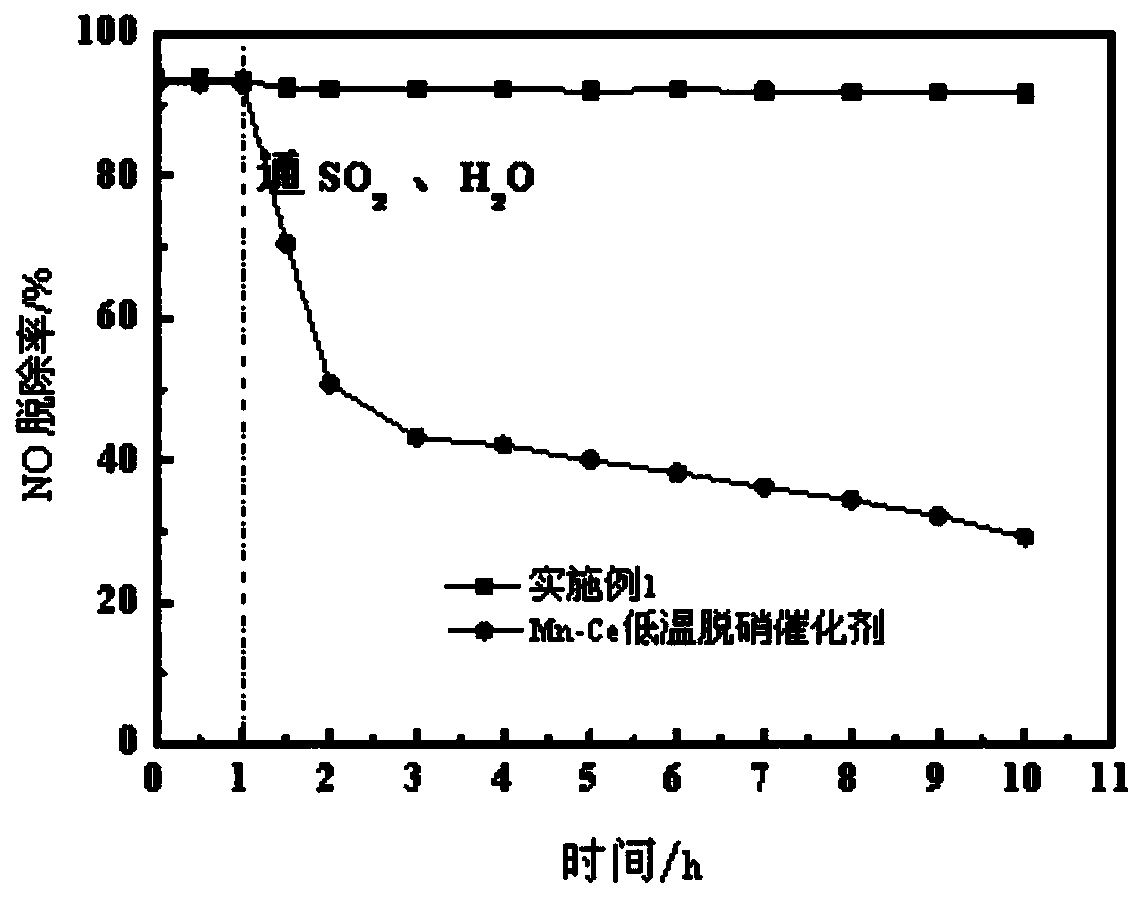

A low-temperature denitrification and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of easy sulfur poisoning and service life, and achieve easy poisoning, prolong service life, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

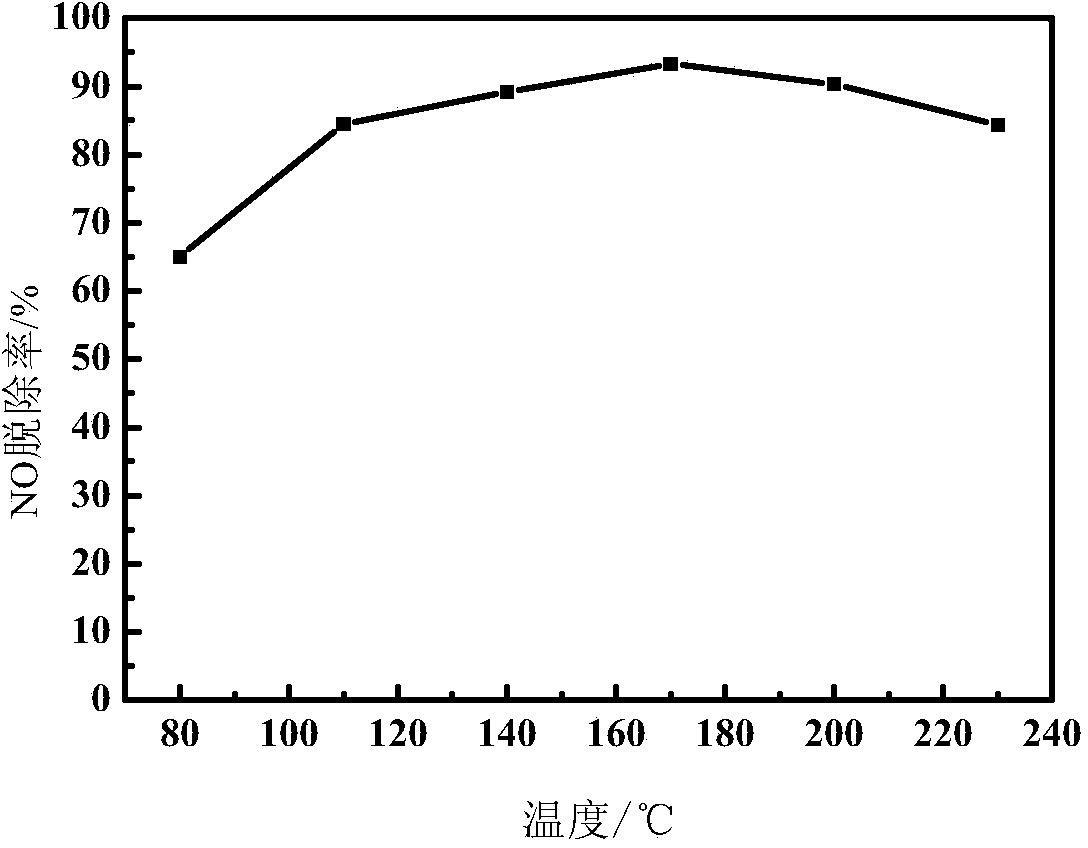

Examples

Embodiment 1

[0031] 1. Preparation of film stock solution

[0032] Weighing stabilizer hydroxyethyl cellulose (HEC) 1.5g (1.5%), functional additive sodium methyl siliconate 3g (3%), PTEF emulsion, pore-forming agent polyethylene glycol (400) 3g (3%) ), the PTFE emulsion 92.5g (92.5%) of 3% film-forming agent. Then they were mixed and stirred at a constant temperature, the stirring speed was 2000 rpm, mechanical stirring was carried out for 15 minutes, and the temperature was 30°C. Make a thin film stock solution.

[0033] 2. Preparation of low temperature catalyst substrate

[0034] Raw material calculation: Weigh the mass of carrier honeycomb ceramics, according to the active component of the catalyst, manganese-cerium composite oxide accounts for 8% of the carrier, and the element molar ratio of Mn / Ce is 1:0.2; the catalyst additive is 2% of the carrier mass, Ni The molar ratio of / Co / Cu / Sb / Nb is 1:0.5:0.75:0.25:0.3, and the active component precursors manganese nitrate and cerium ni...

Embodiment 2

[0049] 1. Preparation of film stock solution

[0050] Weighing stabilizer hydroxypropyl cellulose (HPMC) 0.5g (0.5%), functional additive sodium methyl siliconate 0.5g (0.5%), pore-forming agent ethanol 0.5g (0.5%), film-forming agent 1% 98.5 g (98.5%) of PTFE emulsion. Then they were mixed and stirred at a constant temperature, the stirring speed was 100 rpm, mechanical stirring was performed for 30 minutes, and the temperature was 60°C. Make a thin film stock solution.

[0051] 2. Preparation of low temperature catalyst substrate

[0052] Calculation of raw materials: Weigh the mass of the carrier molecular sieve, according to the active component of the catalyst, manganese-cerium composite oxide accounts for 15% of the carrier, the element molar ratio of Mn / Ce is 1:0.5; the catalytic aid is 1% of the carrier mass, Ni / Ce The molar ratio of Co / Cu / Sb / Nb elements is 1:0.1:0.1:0.1:0.1, and the active component precursors manganese acetate and cerium sulfate and the catalytic ...

Embodiment 3

[0061] 1. Preparation of film stock solution

[0062] Weighing stabilizer polyvinyl alcohol (PVA) 2g (2%), functional auxiliary agent sodium methyl siliconate 3g (3%), pore-forming agent ethanol 3g (3%), the PTFE emulsion 92g ( 92%). Then they were mixed and stirred at a constant temperature, the stirring speed was 1500 rpm, mechanical stirring was performed for 5 minutes, and the temperature was 25°C. Make a thin film stock solution.

[0063] 2. Preparation of low temperature catalyst substrate

[0064] Calculation of raw materials: Weigh the mass of the carrier activated carbon fiber, according to the active component of the catalyst, manganese-cerium composite oxide accounts for 9% of the carrier, and the element molar ratio of Mn / Ce is 1:1; the catalytic promoter is 3% of the carrier mass, Ni The molar ratio of / Co / Cu / Sb / Nb is 1:1:1:0.5:0.5, and the active component precursors manganese nitrate and cerium sulfate and the catalytic aid precursors nickel nitrate, cobalt a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com