SCR (selective catalytic reduction) denitration catalyst for accelerating ammonium hydrogen sulfate decomposition by low-temperature flue gas, preparation method and application

A denitrification catalyst, ammonium bisulfate technology, applied in the field of SCR denitrification catalyst, can solve the problems of increased NOx emission concentration and lower denitrification activity, and achieve the effect of promoting low-temperature decomposition, simple preparation method, and promoting decomposition behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

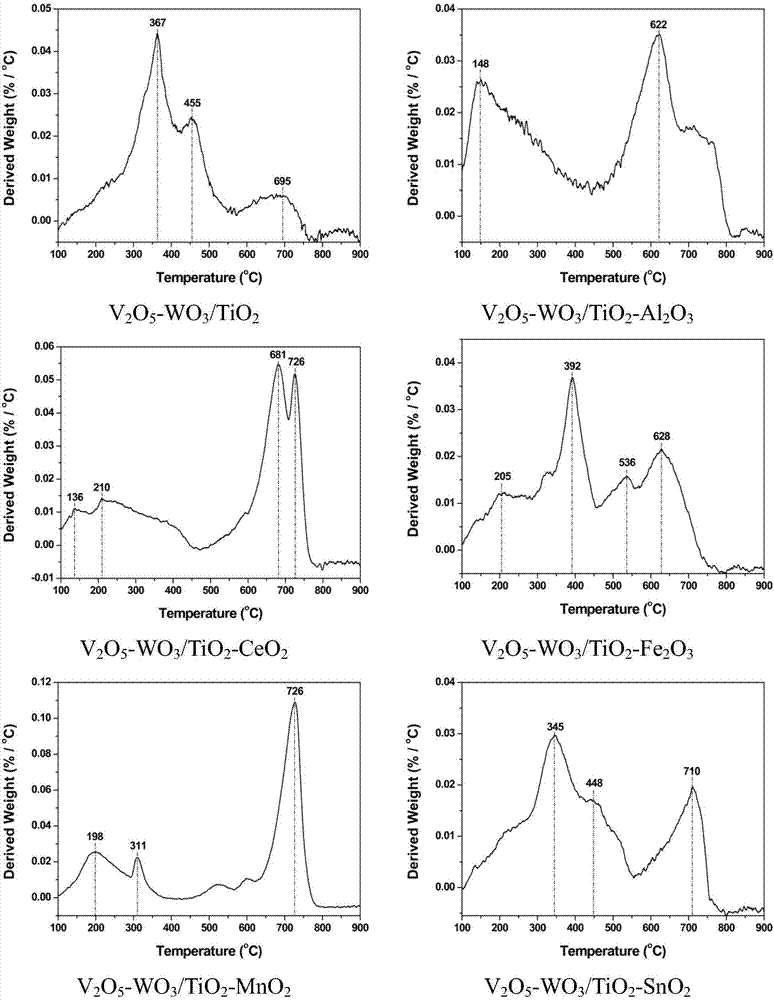

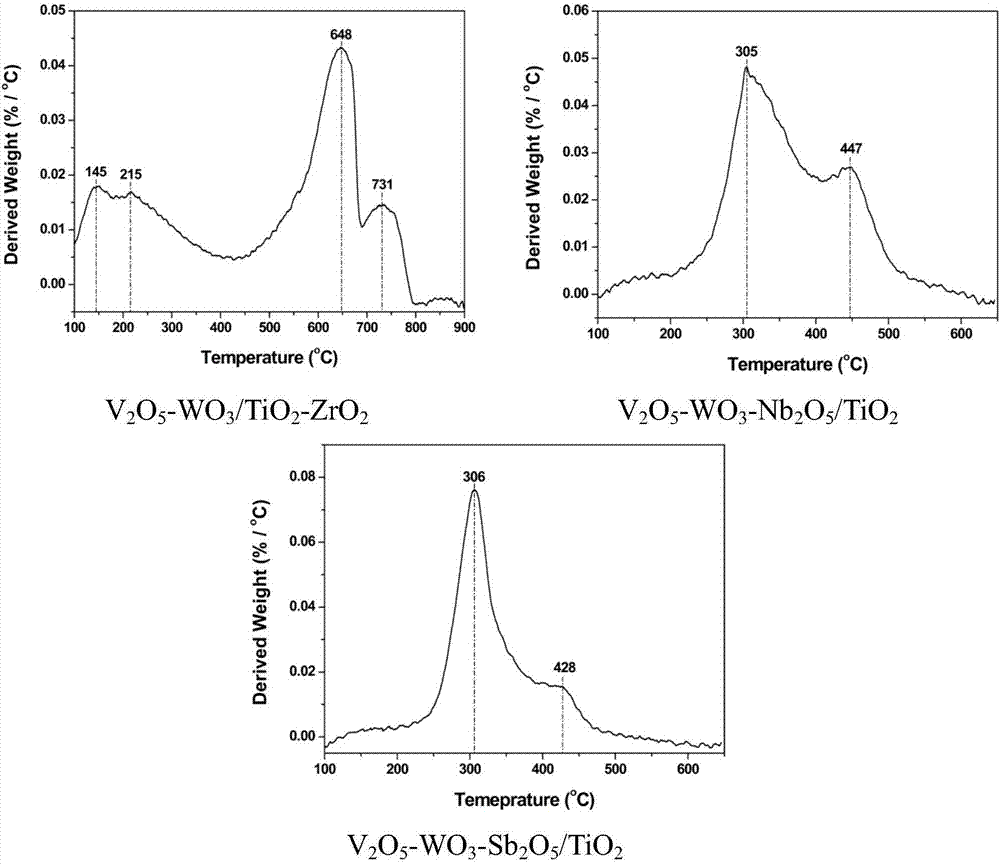

Image

Examples

Embodiment 1

[0035] The catalyst raw materials are: 11.0674g of titanium sulfate, 3.4687g of stannous chloride, 0.1543g of ammonium metavanadate, and 0.3281g of ammonium tungstate;

[0036]Preparation method: first dissolve titanium sulfate and stannous chloride in dilute sulfuric acid, then slowly add the titanium sulfate solution dropwise to excess ammonia water and stir at a speed of 600r / min for 12h, filter the obtained solid-liquid mixture and Wash 5 times, dry the obtained solid at 110°C for 12h, and calcinate at 500°C for 5h after grinding to obtain carrier powder; dissolve ammonium metavanadate and ammonium tungstate in oxalic acid solution (the molar ratio of oxalic acid to ammonium metavanadate is 2:1 ), to obtain a clear solution, add the carrier powder, use a rotary evaporator to stir at 170r / min for 30min in a water bath at 60°C, and evaporate the water to dryness. The obtained solid is baked at 110°C for 12h, ground and calcined at 500°C for 5h to produce The molar ratio of S...

Embodiment 2

[0038] The catalyst raw materials are: 13.5225g of titanium sulfate, 7.5883g of iron nitrate, 0.1543g of ammonium metavanadate, and 0.3281g of ammonium tungstate;

[0039] Preparation method: first dissolve titanium sulfate and ferric nitrate in dilute sulfuric acid, then slowly add the titanium sulfate solution dropwise to excess ammonia water and stir at a speed of 600r / min for 12 hours, filter and wash the obtained solid-liquid mixture for 5 times , the obtained solid was baked at 110°C for 12 hours, and after grinding, it was calcined at 500°C for 5 hours to obtain carrier powder; dissolving ammonium metavanadate and ammonium tungstate in oxalic acid solution to obtain a clear solution, adding carrier powder, and using a rotary evaporator in a 60°C water bath Stir at 170r / min for 30min and evaporate the water to dryness. The obtained solid is baked at 110°C for 12h, ground and calcined at 500°C for 5h, and the molar ratio of Fe element to Ti element is 1:3, V 2 o 5 、WO 3...

Embodiment 3

[0041] The catalyst raw materials are: 14.8657g of titanium sulfate, 7.7456g of aluminum nitrate, 0.1543g of ammonium metavanadate, and 0.3281g of ammonium tungstate;

[0042] Preparation method: first dissolve titanium sulfate and aluminum nitrate in dilute sulfuric acid, then slowly add the titanium sulfate solution dropwise to excess ammonia water and stir at a speed of 600r / min for 12 hours, filter and wash the obtained solid-liquid mixture for 5 times , the obtained solid was baked at 110°C for 12 hours, and after grinding, it was calcined at 500°C for 5 hours to obtain carrier powder; dissolving ammonium metavanadate and ammonium tungstate in oxalic acid solution to obtain a clear solution, adding carrier powder, and using a rotary evaporator in a 60°C water bath Stir at 170r / min for 30min and evaporate the water to dryness. The obtained solid is baked at 110°C for 12h, ground and calcined at 500°C for 5h, and the molar ratio of Al to Ti is 1:3, V 2 o 5 、WO 3 with TiO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com