Method for optimized regulation of SCR (Selective Catalyst Reduction) flue gas denitration system in coal-fired power plant

A technology for coal-fired power plants and adjustment methods, which is applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as the optimization and adjustment method of coal-fired SCR flue gas denitrification systems that have not yet been reported, and ensure safe and stable operation. , the effect of avoiding scaling and reducing the amount of escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

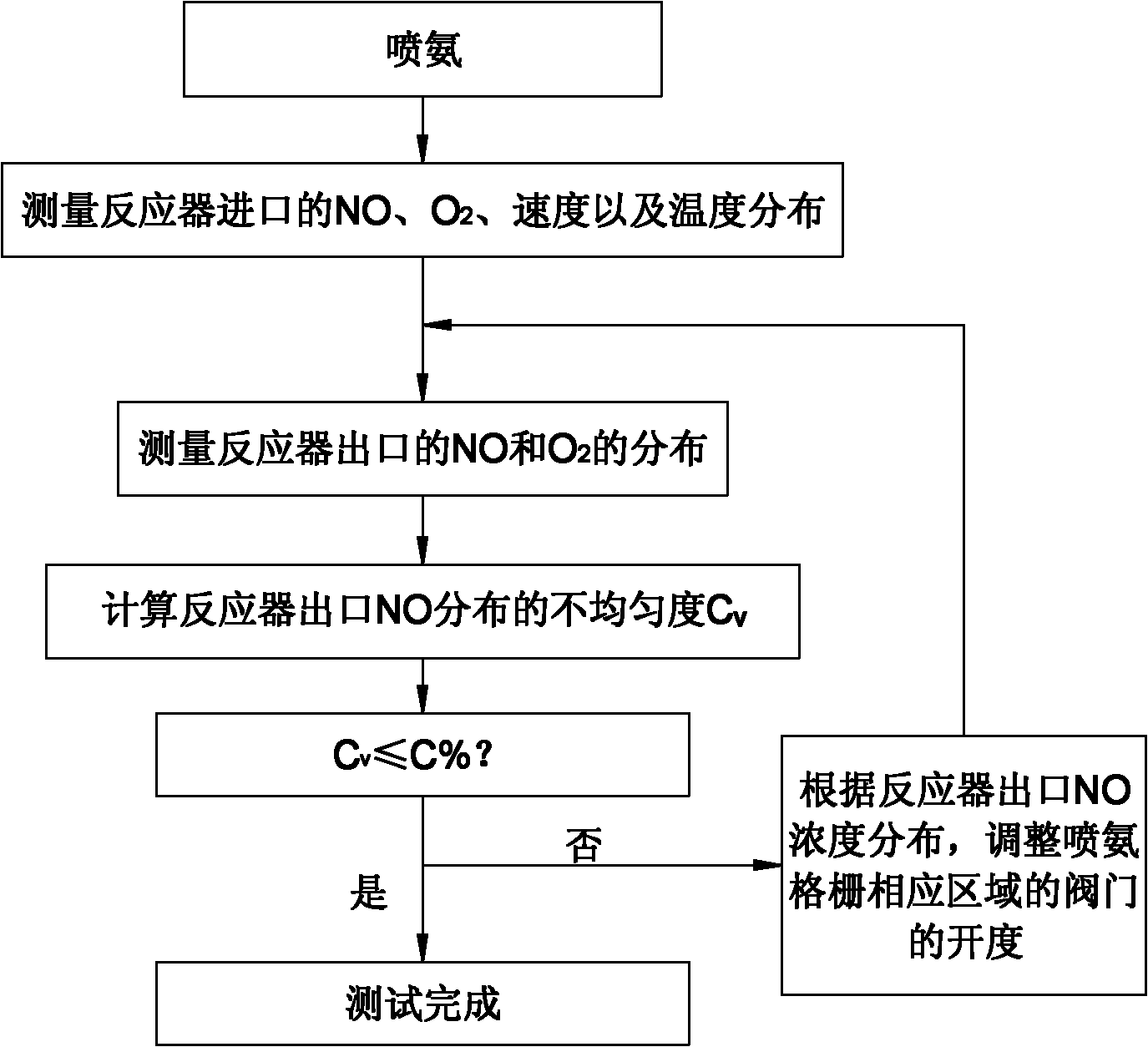

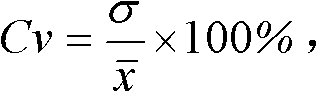

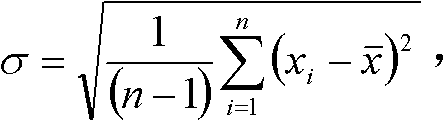

Method used

Image

Examples

Embodiment Construction

[0017] Apply technical scheme of the present invention in concrete power plant:

[0018] The ammonia injection technology of the denitrification system of #4 furnace in Zhejiang Ninghai Power Plant adopts the linear control injection grid ammonia injection method. 10 ammonia injection pipes are arranged horizontally in the ammonia injection flue, and 10 ammonia injection pipes are arranged on both sides of the ammonia injection flue in the longitudinal direction. Root ammonia injection pipes, the ammonia injection volume of each ammonia injection pipe can be adjusted independently. The ammonia slip of the denitrification system is adjusted from 1.8ppm to 1.2ppm through the technical scheme of the invention, and the ammonia slip is reduced by 33%.

[0019] The denitrification system of #6 unit of Zhejiang Beilun Power Plant adopts the vortex static mixing injection method to realize the uniform mixing of ammonia gas and flue gas. The A and B denitrification reactors are each eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com