High-efficiency cleaning mineral separation process of complicated sulfuration mine

A beneficiation method and technology for sulfide ore, which are applied in flotation, solid separation and other directions, can solve the problem of producing a large amount of harmful gases such as hydrogen sulfide, and achieve the effect of good activation effect and high separation index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

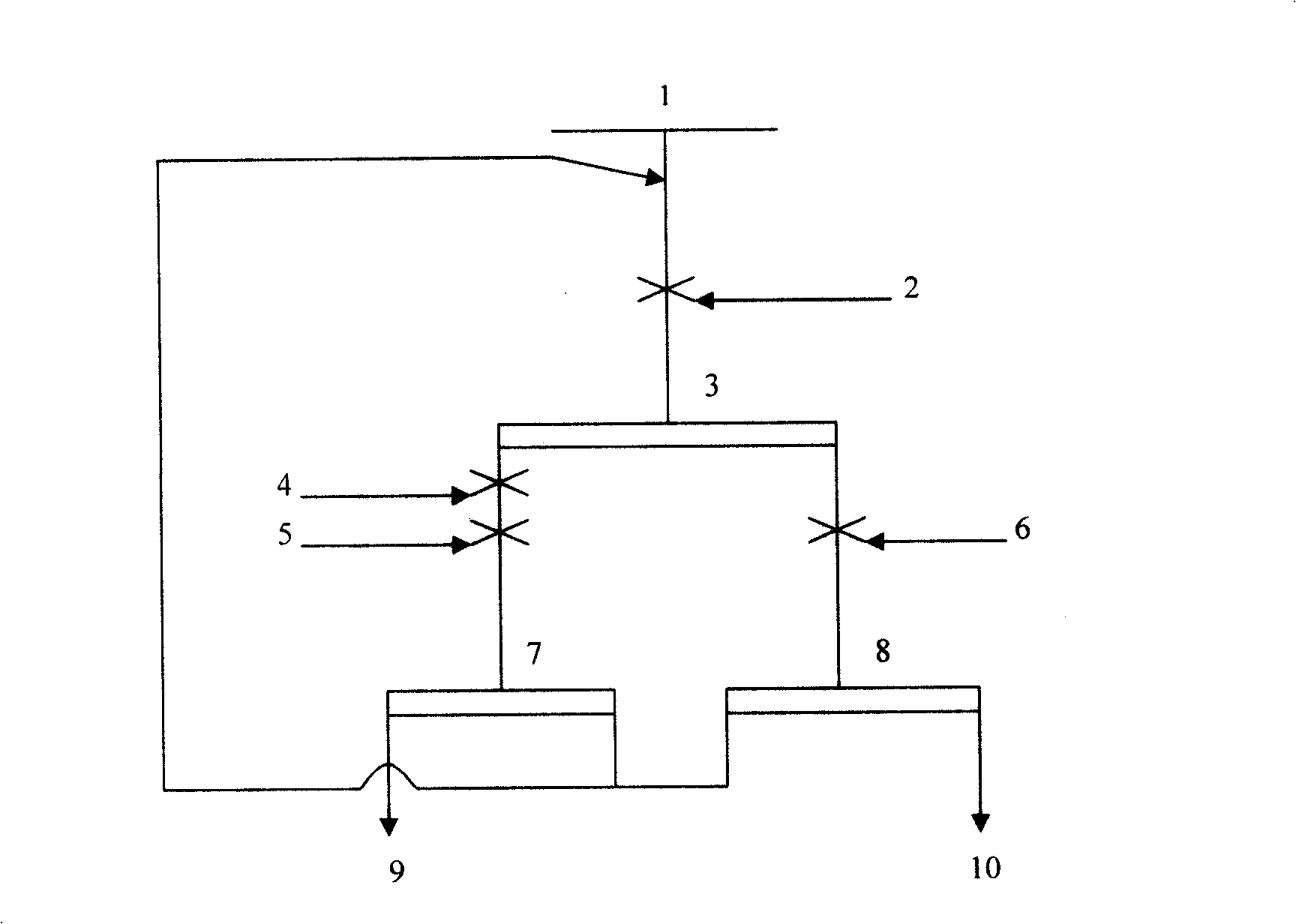

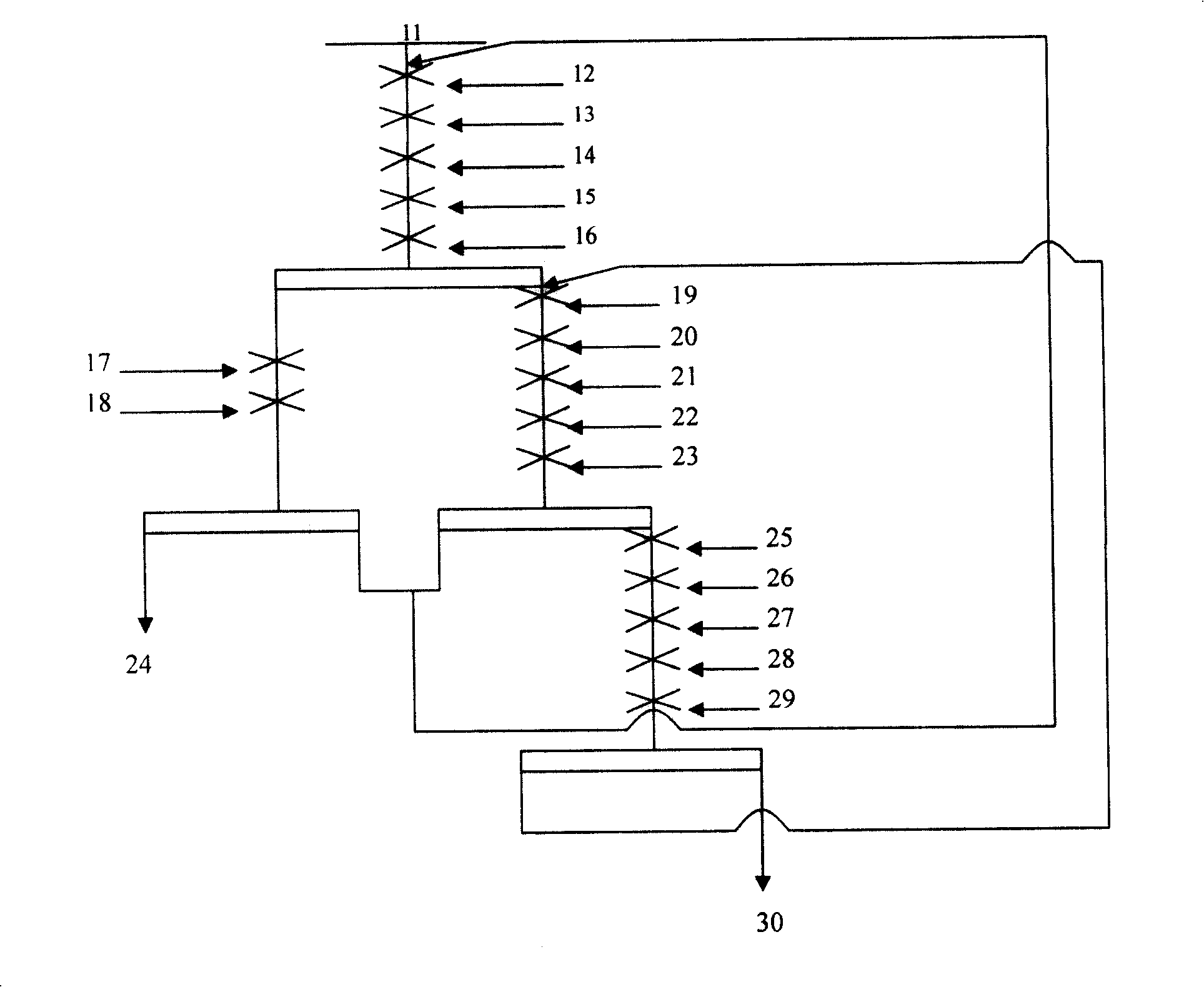

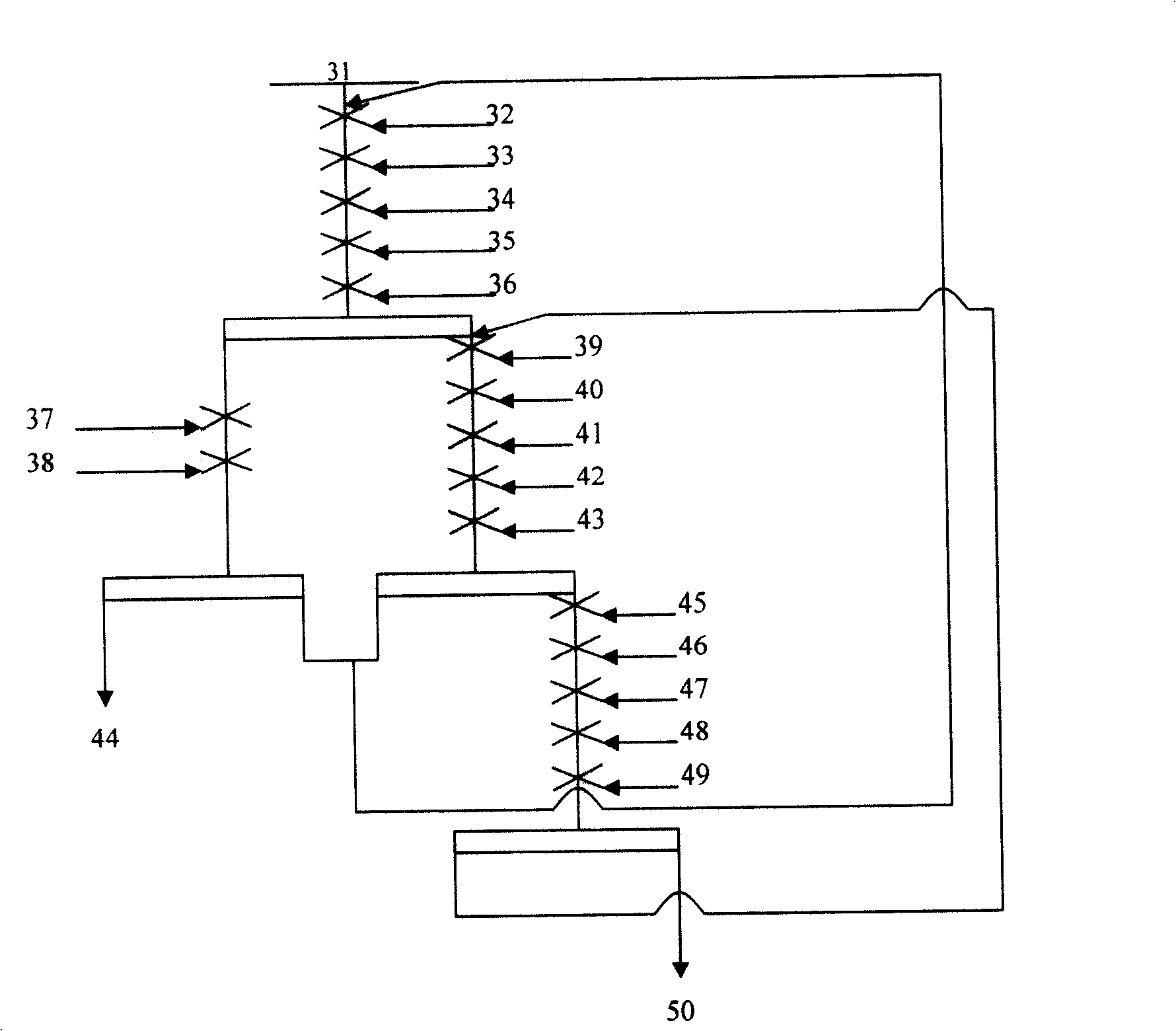

Method used

Image

Examples

Embodiment 1

[0019] By adopting the high-efficiency and clean sulfur separation method described in the present invention, a small-scale test and an industrial test were carried out on copper tailing sulfur separation in a certain mine, and a good separation index was obtained. The sulfur element in this ore mainly exists in three forms: chalcopyrite, pyrrhotite and pyrite. Chalcopyrite is closely related to gangue, and the coarse, medium and fine particles mainly distributed in medium and fine particles are extremely unevenly distributed. The particle size of pyrite embedding is relatively coarse. The distribution of magnetite and pyrrhotite is finer. In short, its ore is a refractory polymetallic ore with fine particles embedded in it. The raw ore containing 1.07% copper, 18.13% sulfur, and 32.61% iron has undergone talc flotation, copper partial flotation, copper-sulfur mixed flotation, mixed The roughing concentrate and copper concentrate I tailings are then ground to -0.045mm, accou...

Embodiment 2

[0021] The raw ore of a copper mine has low sulfur content, the ratio of sulfur to copper is 2:1, and the recoverable effective sulfur is only about 1%. pyrrhotite (Fe 5 S 6 ) is one of the main sulfide minerals in the ore. It is mainly irregularly embedded in gangue minerals or in the gap between magnetite and gangue minerals, cementing and replacing magnetite, and the two are closely related, and secondly, it is filled in network veins along the gangue mineral cracks or gaps. The intercalation relationship between pyrrhotite and chalcopyrite is also very close, and chalcopyrite filling is often seen in the pyrrhotite gap, and there are fine inclusions of chalcopyrite in pyrrhotite. The particle size distribution of pyrrhotite is uneven, mainly between 20 and 295 μm, which is coarser than that of chalcopyrite. Since pyrrhotite is mostly embedded in cemented metasomatous magnetite, fine-grained pyrrhotite and magnetite are not easy to separate as monomers, and both pyrrhoti...

Embodiment 3

[0023] The total iron content of an iron ore in Xinjiang is 50.76%, and the sulfur content is 10.07%. The iron minerals in the ore are mainly magnetite, and the sulfur mainly exists in the form of pyrrhotite and pyrite. The raw ore was ground to -0.074mm to account for 85%, and a rough magnetic separation test was carried out, and an iron concentrate with an iron grade of 64.07% and an iron recovery rate of 86.40% was obtained. However, since the pyrrhotite with strong magnetism is also enriched in the iron concentrate during the magnetic separation process, the sulfur content of the iron concentrate rises to 10.47%, which cannot be utilized. For this reason, adopt method of the present invention, after adding 2000 gram / ton ammonium carbonate, 1000 gram / ton ammonium bicarbonate and 800 gram / ton ferrous sulfate activation, carry out this iron concentrate with 240 gram / ton butyl xanthate One crude, two fine, one sweep, reverse flotation desulfurization. The sulfur content in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com