Method for determining N-methylamino ammate in production of acesulfame

A technique for ammonium acetoacetylsulfamate and a determination method, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of incomplete detection chromatographic conditions, low accuracy of measurement data, and inability to accurately measure the content, etc., to achieve improved Product quality, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

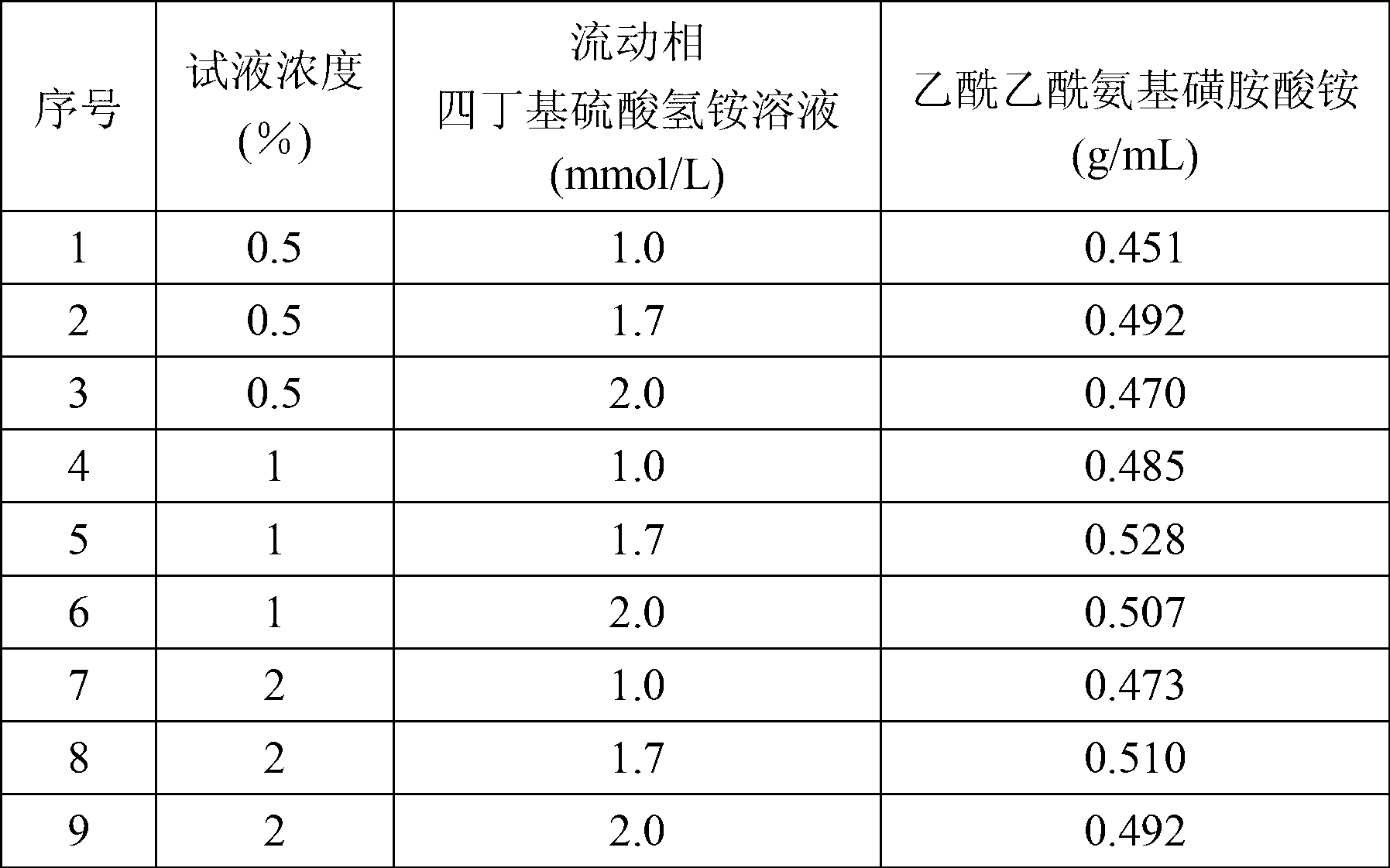

[0023] (2) Preparation of mobile phase: prepare tetrabutylammonium hydrogensulfate solution with deionized water to a molar concentration of 1.0~2.0mmol / L, prepare tetrabutylammonium hydrogensulfate solution and chromatographic grade methanol by volume ratio of 60:40 to make mobile phase;

[0024] (3) Preparation of the test solution: take an appropriate amount of the sample to be tested, dilute the sample to be tested by volume ratio to a concentration of 0.5% to 2.0% with anhydrous methanol, and prepare a test solution;

[0025] (4) liquid chromatography analysis: draw test solution with micro syringe, inject high performance liquid chromatography, analyze with area external standard method;

[0026] (5) Record the content of ammonium acetoacetylsulfamate in the sample to be tested.

[0027] In actual operation, before the liquid chromatography analysis, the correction factor of the area external standard method is established first, and a complete analysis method of the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com