Process and equipment for producing potassium sulfate compound fertilizer by integrally utilizing tail gas generated in sulphuric acid production

A technology of potassium sulfate compound fertilizer and sulfuric acid production, which is applied in the production process and equipment of compound fertilizer, and in the field of ammonium production of potassium sulfate compound fertilizer. It can solve the problems of ammonium tank expansion and the difficulty of normal production and operation of enterprises, and achieve cost savings. , Convenient manufacturing and processing, and the effect of reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

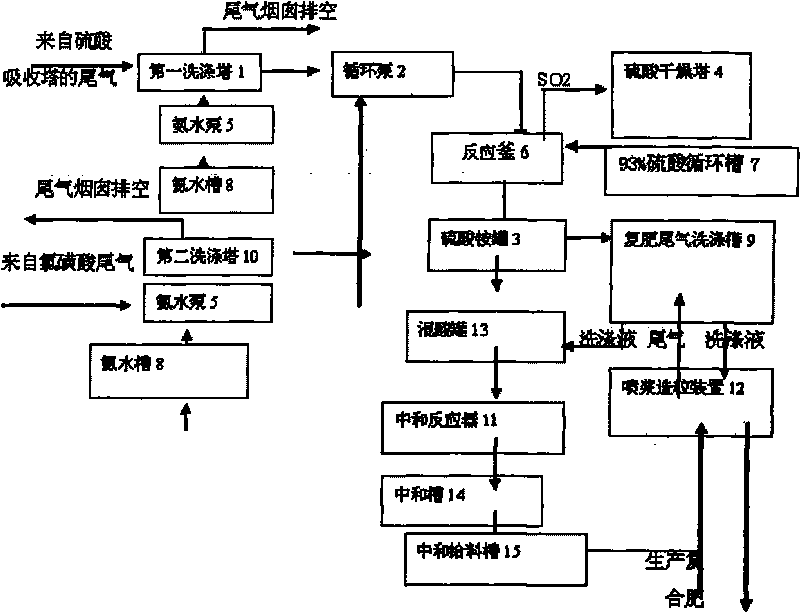

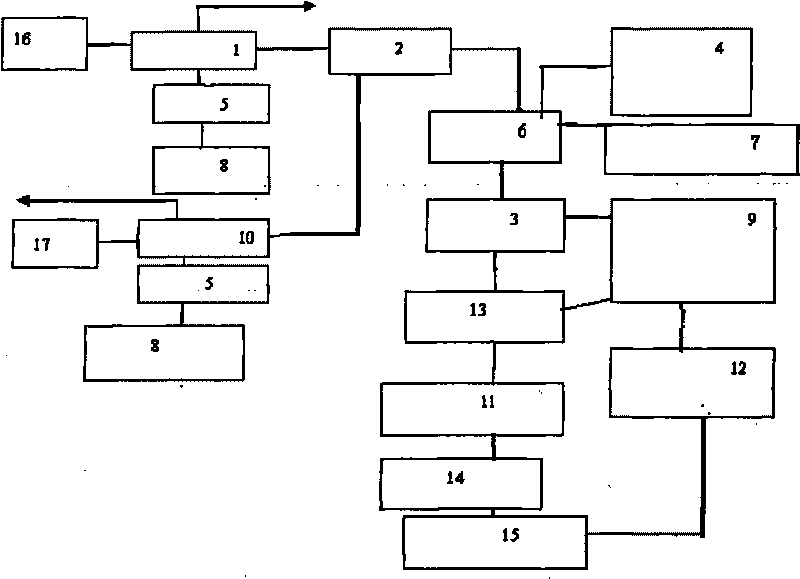

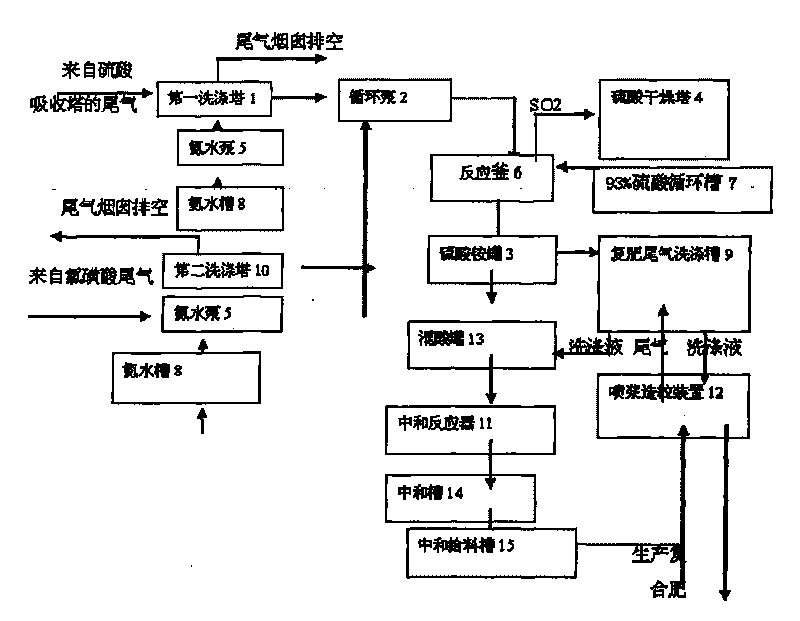

Image

Examples

Embodiment 1

[0038] A process for comprehensively utilizing tail gas from sulfuric acid production to produce potassium sulfate compound fertilizer, comprising the following steps:

[0039] (1) 330,000 m 3 Contains 1950mg / m 3 SO 2 The sulfuric acid tail gas is delivered to the first washing tower 1, and 3m is added to the first washing tower 1 from the ammonia water tank 8 through the ammonia water pump 5 3 Mass concentration is 18% ammoniacal liquor, ammoniacal liquor and the sulfuric acid tail gas in the first washing tower generate the solution that contains ammonium bisulfite and ammonium sulfite, gas is exhausted through the first washing tower 1 chimney, in the first washing tower 1 The mass ratio of the generated ammonium bisulfite to ammonium sulfite is 2.16:1, and the total concentration is 278g / l; after absorption, the tail gas emits SO 2 Concentration 589mg / m 3 .

[0040] (2) will 100,000 m 3 Contains 3000mg / m 3 SO 2 The chlorosulfonic acid tail gas is transported in the...

Embodiment 2

[0048] A process for comprehensively utilizing tail gas from sulfuric acid production to produce potassium sulfate compound fertilizer, comprising the following steps:

[0049] (1) 330,000 m 3 Contains 1850mg / m 3 SO 2 The sulfuric acid tail gas is delivered to the first washing tower 1, and 3m is added to the first washing tower 1 from the ammonia water tank 8 through the ammonia water pump 5 3 Concentration is the ammoniacal liquor of 15%, ammoniacal liquor and the sulfuric acid tail gas in the first washing tower generate the solution that contains ammonium bisulfite and ammonium sulfite, gas is exhausted through the first washing tower 1 chimney, and in the first washing tower 1 The mass ratio of the generated ammonium bisulfite to ammonium sulfite is 2.08:1, and the total concentration is 252g / l; the tail gas SO after absorption 2 Emission concentration 301mg / m 3 .

[0050] (2) will 100,000 m 3 Contains 2600mg / m 3 SO 2 The chlorosulfonic acid tail gas is transporte...

Embodiment 3

[0056] A process for comprehensively utilizing tail gas from sulfuric acid production to produce potassium sulfate compound fertilizer, comprising the following steps:

[0057] (1) 330,000 m 3 Contains 1630mg / m 3 SO 2 The sulfuric acid tail gas is delivered to the first washing tower 1, and 3m is added to the first washing tower 1 from the ammonia water tank 8 through the ammonia water pump 5 3 Concentration is 10% ammoniacal liquor, ammoniacal liquor and the sulfuric acid tail gas in the first scrubber 1 generate the solution that contains ammonium bisulfite and ammonium sulfite, gas is exhausted through the first scrubber 1 chimney, and in the first scrubber 1 The mass ratio of the produced ammonium bisulfite to ammonium sulfite is 2.69:1, and the total concentration is 218g / l; after absorption, the tail gas emits SO 2 Concentration 10mg / m 3 .

[0058] (2) will 100,000 m 3 Contains 1880mg / m 3 SO 2 The chlorosulfonic acid tail gas is transported in the second washing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com