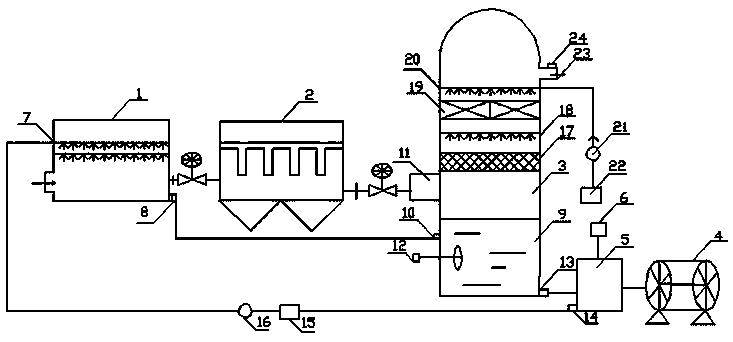

Technology and device for reducing drag of desulfurization tower of flue gas desulfurization system of sintering machine

A desulfurization system and sintering machine technology, applied in the direction of dispersed particle separation, chemical instruments and methods, and the use of liquid separation agents, can solve problems such as packing blockage and blockage, and achieve the effects of reducing blockage, reducing precipitation rate, and reducing tower resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A process for reducing resistance of a desulfurization tower in a flue gas desulfurization system of a sintering machine, characterized in that it comprises the following steps:

[0042] 1) Pretreatment: Use a gas efficient water-cooled dust removal device to spray and wash the flue gas of the sintering machine. The washing liquid is ammonium sulfate mother liquor. The ph value of ammonium sulfate mother liquor is 3.5. There are a lot of solid particles such as smoke and dust in the gas. After washing, the temperature of the flue gas is 70°C. The washed ammonium sulfate solution is filtered and then introduced into the solution collection tank at the bottom of the desulfurization tower. The washed sintering machine flue gas is introduced into the bag The type dust collector further removes the fine particles in the smoke;

[0043] 2) Countercurrent absorption treatment: the sintering machine flue gas that has passed step 1) is passed into the desulfurization tower, and ...

Embodiment 2

[0050] A process for reducing resistance of a desulfurization tower in a flue gas desulfurization system of a sintering machine, characterized in that it comprises the following steps:

[0051] 1) Pretreatment: Use a gas efficient water-cooled dedusting device to spray and wash the flue gas of the sintering machine. The washing liquid is ammonium sulfate mother liquor. There are a lot of solid particles such as smoke and dust in the gas. After washing, the temperature of the flue gas is 60°C. The washed ammonium sulfate solution is filtered and then introduced into the solution collection tank at the bottom of the desulfurization tower. The washed sintering machine flue gas is introduced into the bag The type dust collector further removes the fine particles in the smoke;

[0052] 2) Countercurrent absorption treatment: the sintering machine flue gas that has passed step 1) is passed into the desulfurization tower, and is in contact with the countercurrent shotcrete of the abs...

Embodiment 3

[0059] A process for reducing resistance of a desulfurization tower in a flue gas desulfurization system of a sintering machine, characterized in that it comprises the following steps:

[0060] 1) Pretreatment: Use a gas efficient water-cooled dust removal device to spray and wash the flue gas of the sintering machine. The washing liquid is ammonium sulfate mother liquor. The pH value of ammonium sulfate mother liquor is 4.2. There are a lot of solid particles such as smoke and dust in the gas. After the washing treatment, the flue gas temperature is 65°C. The washed ammonium sulfate solution is filtered and then introduced into the solution collection tank at the bottom of the desulfurization tower. The washed sintering machine flue gas is introduced into the electric The dust collector further removes fine particles in the smoke;

[0061] 2) Countercurrent absorption treatment: the sintering machine flue gas that has passed step 1) is passed into the desulfurization tower, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com