Sintering flue gas desulfurization combined coking coal gas deamination cycling technology and cycling system

A technology for coke oven gas and sintering flue gas, which is applied in the petroleum industry, ammonium sulfate, combustible gas purification, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be further described in detail below with reference to the drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

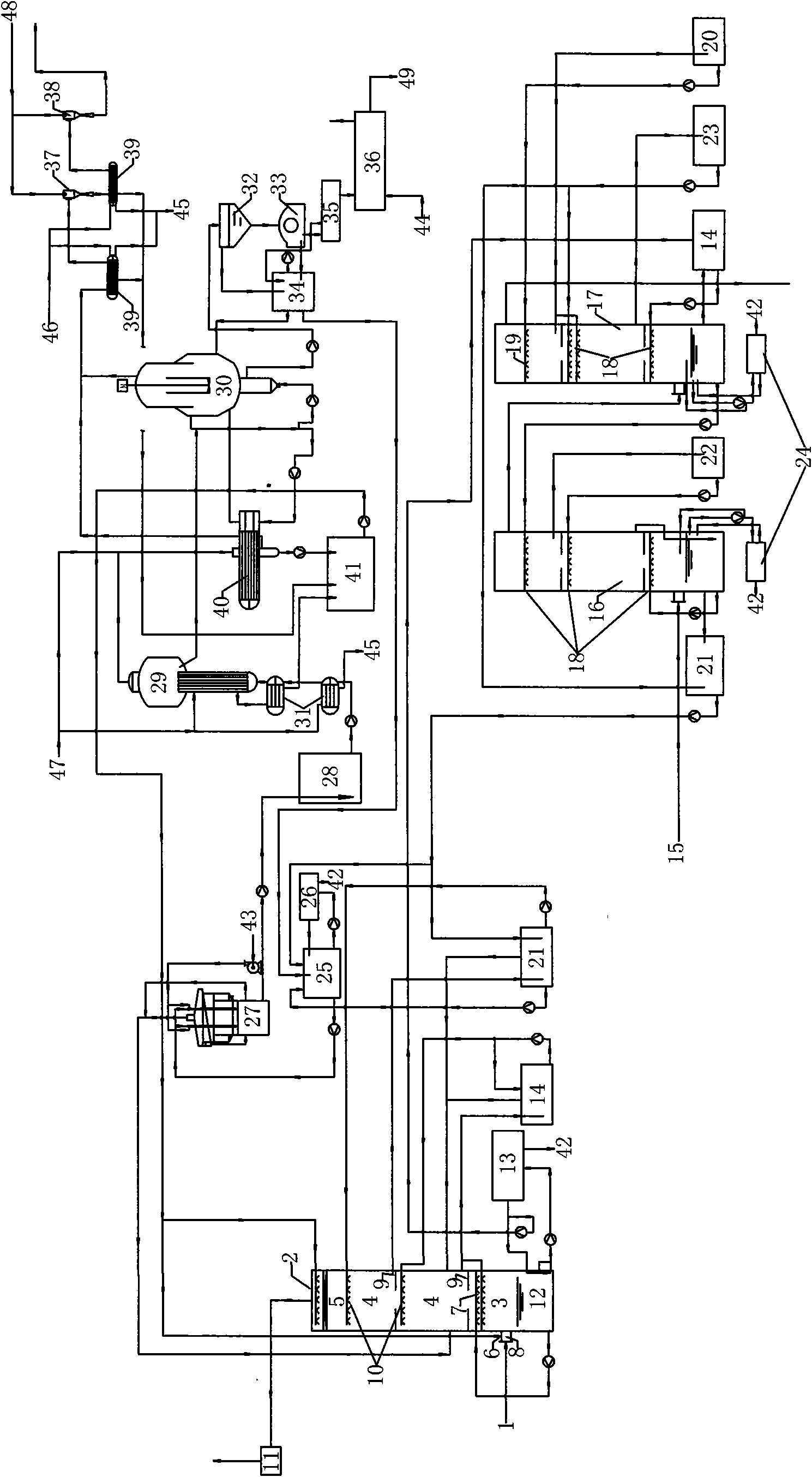

[0047] refer to figure 1 , a sintering flue gas desulfurization combined coke oven gas deammoniation cycle system, including sintering flue gas desulfurization system, coke oven gas deammonization system and ammonium sulfate production system,

[0048] The sintering flue gas desulfurization system includes an ammonium sulfite storage tank 21, a desulfurization absorption tower 2 and an ammonium bisulfite storage tank 14, the ammonium sulfite storage tank 21 is connected to the upper part of the desulfurization absorption tower 2 through a pump, and the bottom of the desulfurization absorption tower is connected to the sulfurous acid Ammonium hydrogen storage tank 14;

[0049] Described coke oven gas deamination system comprises ammonium sulfite stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com