Process for treating a gas stream

A gas and in-gas technology, applied in separation methods, chemical instruments and methods, flow control, etc., can solve the problems of expensive and dangerous ammonia treatment, and achieve the effect of offsetting treatment costs and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention provides a cost-effective process for the treatment of gases, such as hydrocarbon gases, containing hydrogen sulfide and carbon dioxide pollutants. A scrubbing solution comprising ammonium sulfate and ammonium bisulfite is used to react with hydrogen sulfide to form ammonium thiosulfate according to the following general reaction formula:

[0012] 6NH 3 +4SO 2 +2H 2 S+H 2 O→3(NH 4 ) 2 S 2 o 3

[0013] Ammonium thiosulfate is a readily marketable product and can be sold to reduce the cost of gas treatment. In addition, hydrogen sulfide is converted into harmless materials.

[0014] Advantageously, the carbon dioxide does not react with the ammonium sulfate and ammonium bisulfite in the wash liquor. Thus, in contrast to most physical and alkaline solvents, the scrubbing liquid selectively absorbs hydrogen sulfide and repels carbon dioxide within the gas.

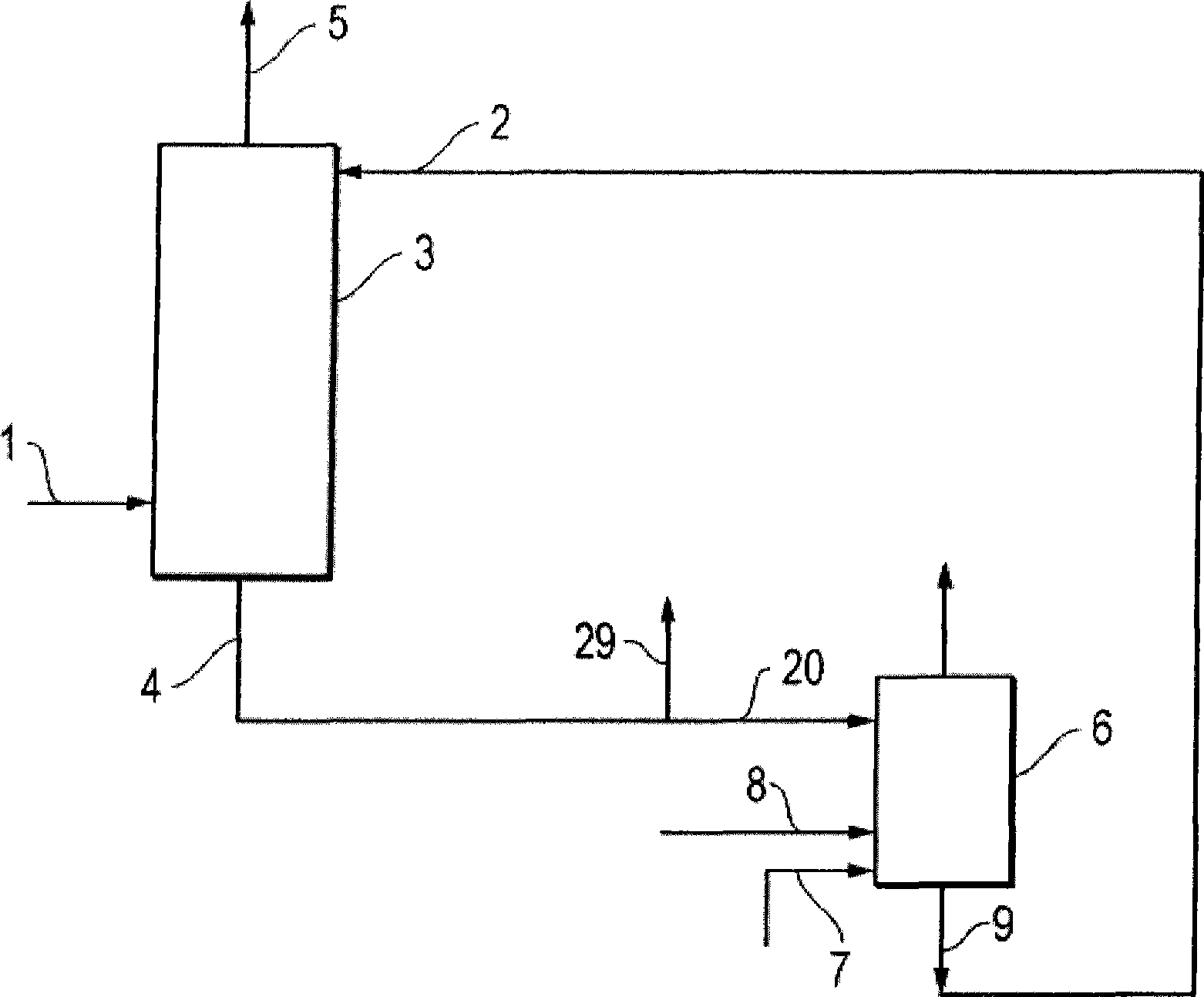

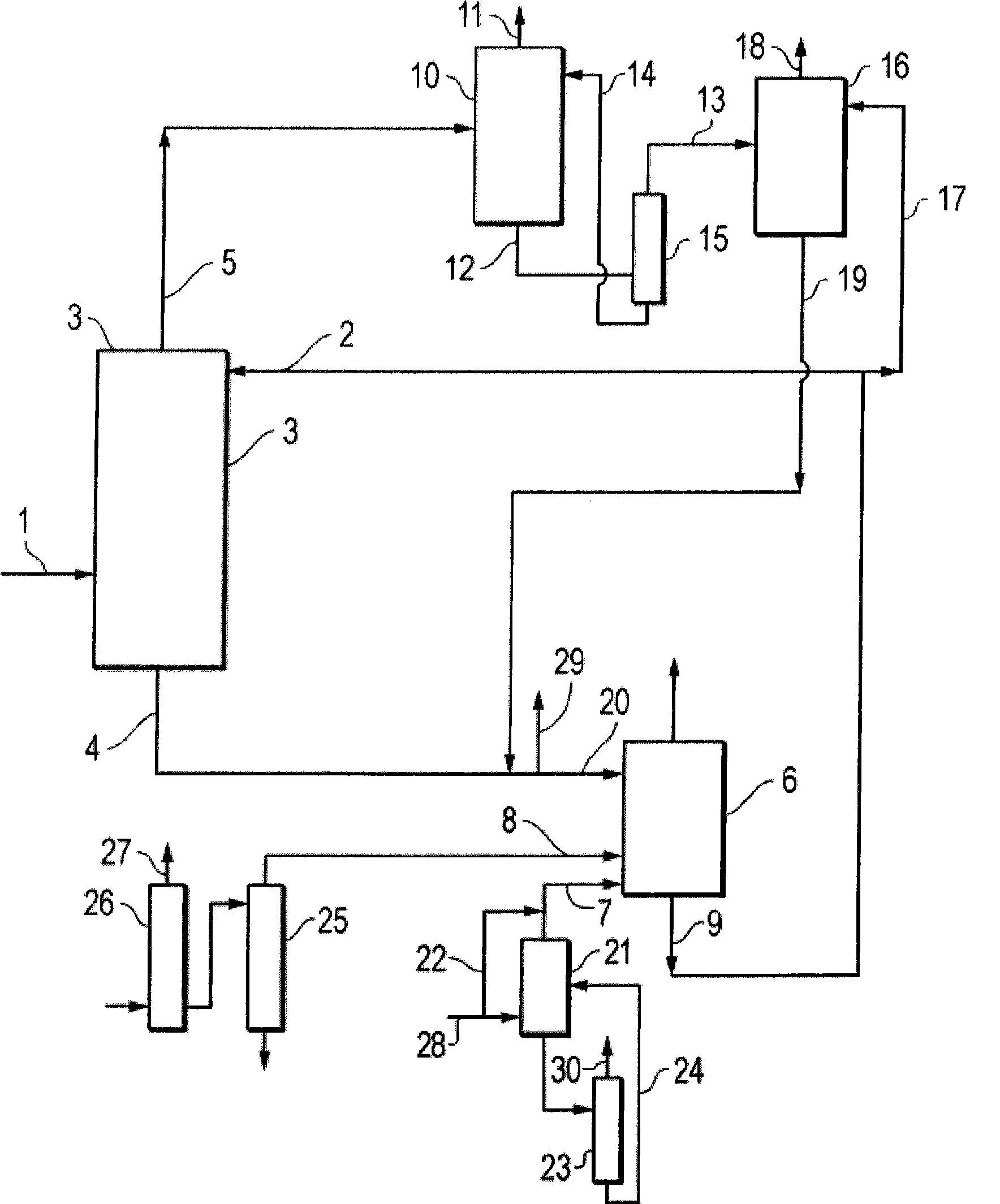

[0015] Such as figure 1 Shown is a first embodiment of a process for removing sulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com