Silicon-based composite cathode material for lithium-ion battery and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of inhibiting agglomeration, inhibiting volume expansion, and improving first-week Coulombic efficiency and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

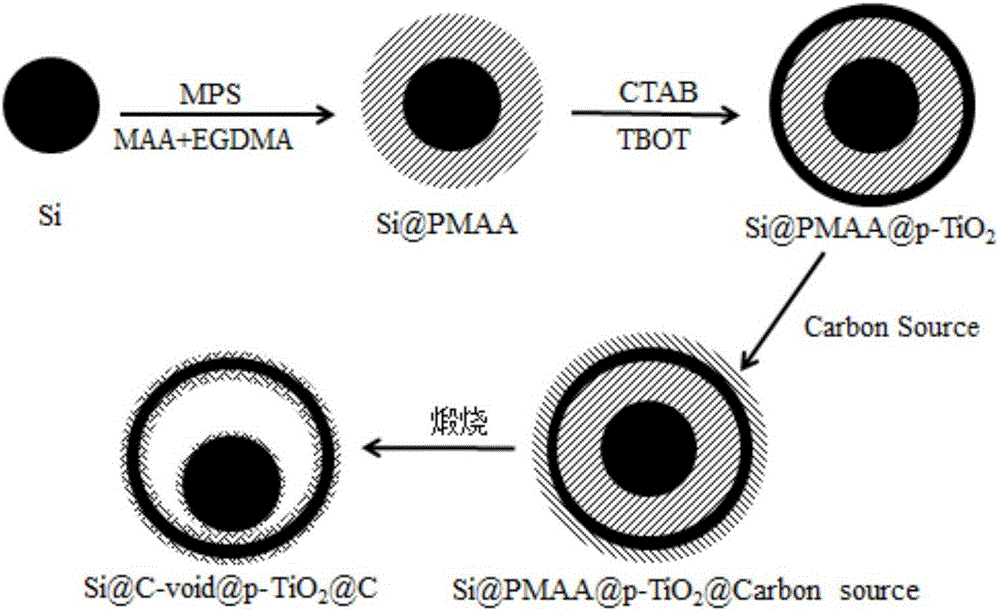

[0037] A method for preparing a silicon-based composite negative electrode material for a lithium-ion battery, comprising the following steps:

[0038] 1) Using the precipitation co-distillation method to coat the organic polymer layer on the surface of the nano-silicon particles to synthesize a composite material with a core-shell structure:

[0039] a) Disperse nano-silicon in the ammonia water-ethanol mixture (V:V, 1:20) according to 1~10g / L, and methacryloyl Oxypropyltrimethoxysilane MPS was slowly added to the mixed liquid, stirred and reacted for 12-24 hours, and modified Si-MPS silicon particles with active double bonds grafted on the surface were obtained;

[0040]b) The modified Si-MPS silicon particles obtained in step a) are based on the modified Si-MPS silicon and methacrylic acid monomer, ethylene glycol dimethacrylate crosslinking agent and azobisisobutyronitrile as the initiator mass The volume ratio is 1:(1~2):(0.5~2):(0.015~0.12) respectively add methacrylic ...

Embodiment 1

[0046] Disperse 0.8 g of silicon spheres with a diameter of about 50 nm into 800 mL of absolute ethanol solution, add 40 mL of 25% ammonia water under stirring conditions, and then slowly add 8 g of methacryloxypropyltrimethoxysilane (MPS) to the above silicon suspension Stir in the turbid solution for 12 hours, wash three times with alcohol and water respectively, and obtain Si-MPS particles with active double bonds grafted on the surface. The resulting 0.8 g Si-MPS particles were ultrasonically dispersed in 107 mL of acetonitrile, 0.8 mL of methacrylic acid (MAA) and 0.4 mL of ethylene glycol dimethacrylate (EGDMA) were added, and 0.012 mL of azobisiso Butyronitrile (AIBN) was used as the initiator, and the composite microspheres Si@PMAA with organic carboxylic acid shells on the surface were obtained by reflux at 90 °C for 1 h. Ultrasonically disperse 0.8g of composite microspheres at 1.0g / L in 800mL of acetonitrile and ethanol (V / V, 1:2) mixture, add 0.4g of cetyltrimethyl...

Embodiment 2

[0050] Disperse 1.6g of silicon spheres with a diameter of about 50nm into 800mL of absolute ethanol solution, add 40mL of 25% ammonia water under stirring conditions, and then slowly add 24g of methacryloxypropyltrimethoxysilane (MPS) to the above silicon in the suspension, stirred for 20 hours, and washed three times with alcohol and water respectively to obtain Si-MPS particles grafted with active double bonds on the surface. The resulting 1.6 g of Si-MPS particles were ultrasonically dispersed in 320 mL of acetonitrile, 2.4 mL of methacrylic acid (MAA) and 2.4 mL of ethylene glycol dimethacrylate (EGDMA) were added, and 0.048 mL of azobisisobutyl Nitrile (AIBN) was used as the initiator, and the composite microspheres Si@PMAA with organic carboxylic acid shells on the surface were obtained by reflux at 95 °C for 1.5 h. 2.0g of composite microspheres were ultrasonically dispersed in 800mL of acetonitrile and ethanol (V / V, 1:3) mixture according to 2.5g / L, and 3.2g of cetylt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com