Cos@carbon nano-cage as well as preparation method and application thereof

A carbon nanocage and solution technology, applied in the field of lithium-ion batteries, can solve problems such as structural collapse and reduced cycle stability, and achieve the effects of low cost, good cycle performance, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

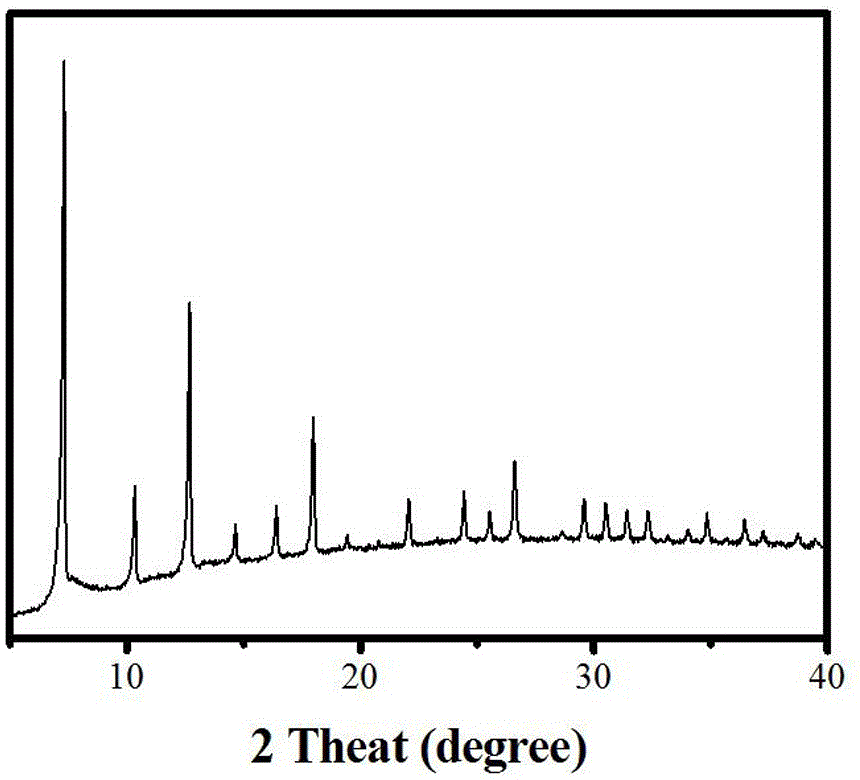

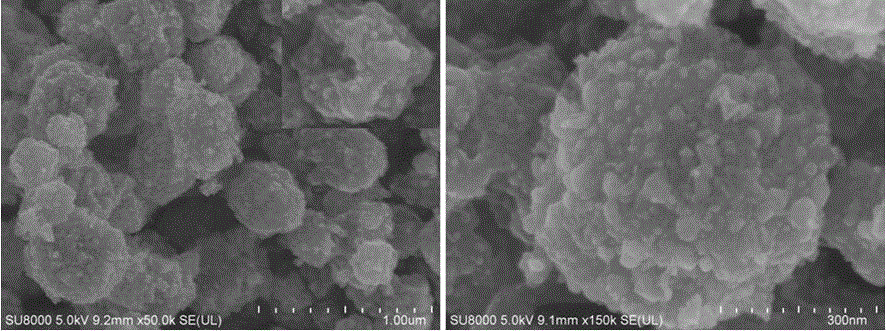

[0024] A method for preparing CoS@carbon nanocages: specifically comprising the following steps:

[0025] 1) Preparation of ZIF-67 precursor: 0.4g of Co(NO 3 ) 2 •6H 2 O and 5.0 g of 2-methylimidazole were dissolved in 5 ml and 19 ml of deionized water respectively, and after the complete dissolution, the Co(NO 3 ) 2 •6H 2 The O solution was added dropwise to the 2-methylimidazole solution, and then 80 mg of polyvinylpyrrolidone (PVP) was added, and stirred at 25 °C for 6 h. The reaction product was washed with deionized water and ethanol for three times, and then dried. The Co@carbon nanocages were obtained by calcination at 550℃ for 4 h in a tube furnace;

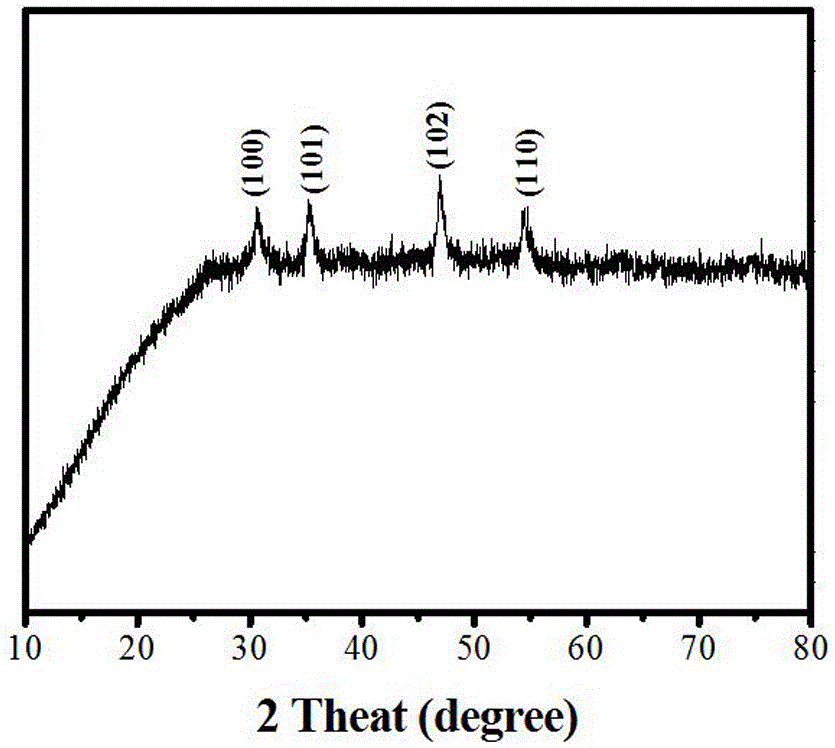

[0026] 2) Weigh 150 mg of Co@carbon nanocages and 30 mg of sulfur powder, mix and grind for 30 minutes, and roast the ground samples in a tube furnace at 360 °C for 2 hours to prepare CoS@carbon nanocages.

[0027] Lithium-ion battery assembly: by mass ratio CoS@carbon nanocage: polytetrafluoroethylene: acetylene bl...

Embodiment 2

[0029] A method for preparing CoS@carbon nanocages: specifically comprising the following steps:

[0030] 1) Preparation of ZIF-67 precursor: 0.5 g of Co(NO 3 ) 2 •6H 2 O and 6.0 g of 2-methylimidazole were dissolved in 5 ml and 20 ml of deionized water respectively, and after the complete dissolution, the Co(NO 3 ) 2 •6H 2 The O solution was added dropwise to the 2-methylimidazole solution, and then 150 mg of polyvinylpyrrolidone (PVP) was added, and stirred at 25 °C for 10 h. The reaction product was washed with deionized water and ethanol for 3 times, and then dried. The Co@carbon nanocages were obtained by calcination at 600℃ for 5 h in a tube furnace;

[0031] 2) Weigh 160 mg of Co@carbon nanocages and 35 mg of sulfur powder, mix and grind for 35 minutes, and roast the ground samples in a tube furnace at 400 °C for 3 hours to prepare CoS@carbon nanocages.

[0032] Lithium-ion battery assembly: by mass ratio CoS@carbon nanocage: polytetrafluoroethylene: acetylene bla...

Embodiment 3

[0034] A method for preparing CoS@carbon nanocages: specifically comprising the following steps:

[0035] 1) Preparation of ZIF-67 precursor: 0.6 g of Co(NO 3 ) 2 •6H 2 O and 6.5 g of 2-methylimidazole were dissolved in 6 ml and 21 ml of deionized water respectively, and after the complete dissolution, the Co(NO 3 ) 2 •6H 2 The O solution was added dropwise to the 2-methylimidazole solution, and then 200 mg of polyvinylpyrrolidone (PVP) was added, stirred at 25 °C for 12 h, and the reaction product was washed with deionized water and ethanol for three times, then dried, The Co@carbon nanocages were obtained by calcination at 650℃ for 6 h in a tube furnace;

[0036] 2) Weigh 180 mg of Co@carbon nanocages and 40 mg of sulfur powder, mix and grind for 40 minutes, and roast the ground samples in a tube furnace at 450 °C for 5 hours to prepare CoS@carbon nanocages.

[0037] Lithium-ion battery assembly: by mass ratio CoS@carbon nanocage: polytetrafluoroethylene: acetylene bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com