A kind of cos@carbon nanocage and its preparation method and application

A carbon nano-cage, 6H2O technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of reduced cycle stability and structural collapse, and achieve the effects of good cycle performance, low cost and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

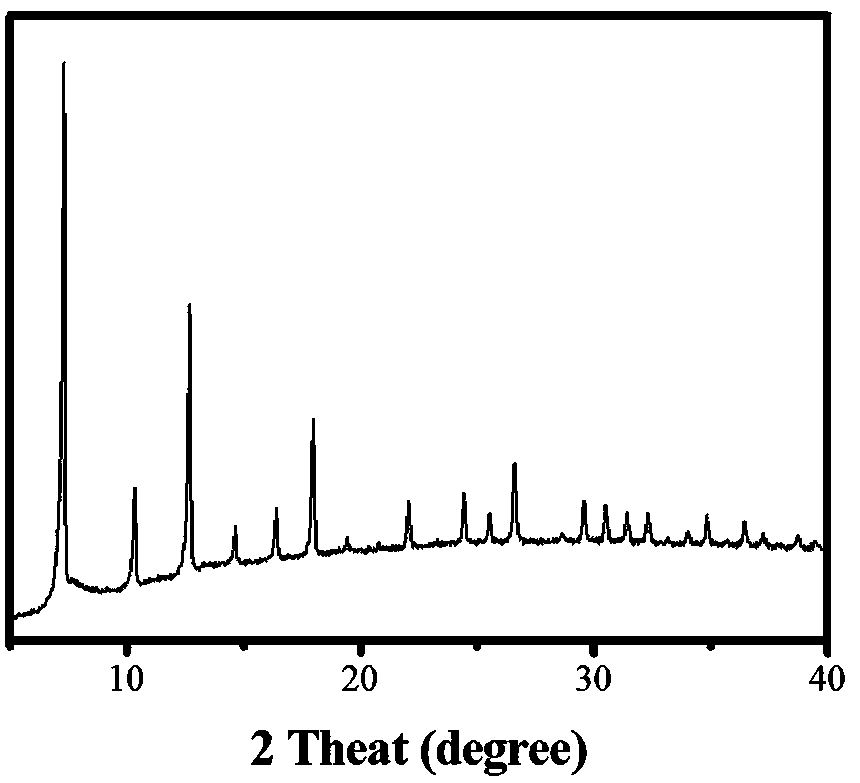

[0024] A method for preparing CoS@carbon nanocages: specifically comprising the following steps:

[0025] 1) Preparation of ZIF-67 precursor: 0.4g of Co(NO 3 ) 2 •6H 2 The 2-methylimidazole of O and 5.0g is dissolved in the deionized water of 5ml and 19ml respectively, after treating to dissolve completely, Co(NO 3 ) 2 •6H 2 The O solution was added dropwise to the 2-methylimidazole solution, and then 80 mg of polyvinylpyrrolidone (PVP) was added, and stirred at 25 °C for 6 h. The reaction product was washed with deionized water and ethanol for three times, and then dried. The Co@carbon nanocages were obtained by calcination at 550℃ for 4 h in a tube furnace;

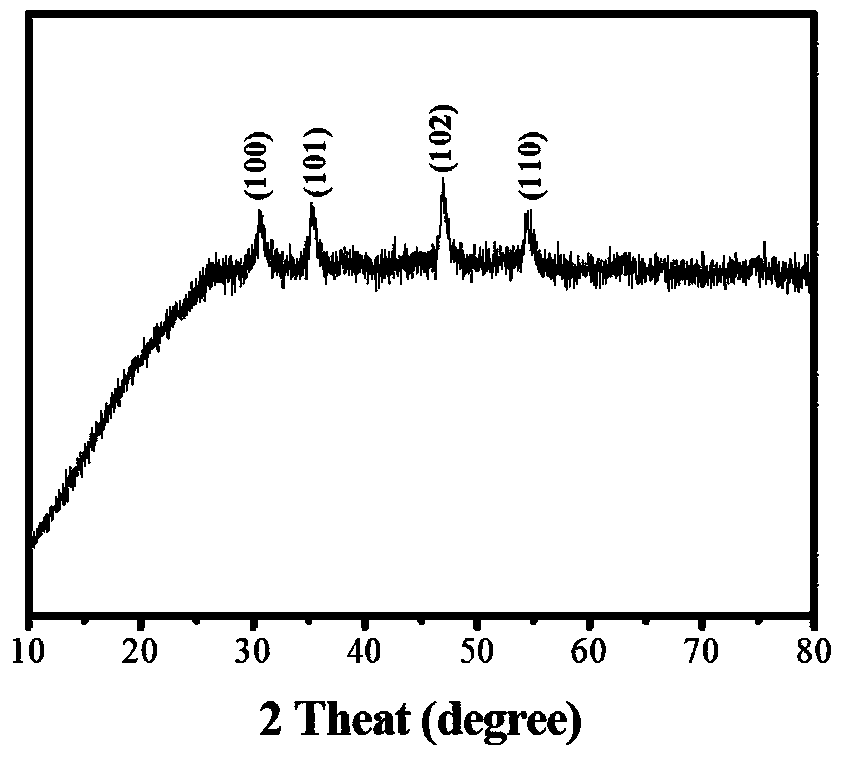

[0026] 2) Weigh 150 mg of Co@carbon nanocages and 30 mg of sulfur powder, mix and grind for 30 minutes, and roast the ground samples in a tube furnace at 360 °C for 2 hours to prepare CoS@carbon nanocages.

[0027] Lithium-ion battery assembly: by mass ratio CoS@carbon nanocage: polytetrafluoroethylene: acetylene ...

Embodiment 2

[0029] A method for preparing CoS@carbon nanocages: specifically comprising the following steps:

[0030] 1) Preparation of ZIF-67 precursor: 0.5 g of Co(NO 3 ) 2 •6H 2 The 2-methylimidazole of O and 6.0g is dissolved in the deionized water of 5ml and 20ml respectively, treats to dissolve completely after Co(NO 3 ) 2 •6H 2 The O solution was added dropwise to the 2-methylimidazole solution, and then 150 mg of polyvinylpyrrolidone (PVP) was added, and stirred at 25 °C for 10 h. The reaction product was washed with deionized water and ethanol for 3 times, and then dried. The Co@carbon nanocages were obtained by calcination at 600℃ for 5 h in a tube furnace;

[0031] 2) Weigh 160 mg of Co@carbon nanocages and 35 mg of sulfur powder, mix and grind for 35 minutes, and roast the ground samples in a tube furnace at 400 °C for 3 hours to prepare CoS@carbon nanocages.

[0032] Lithium-ion battery assembly: by mass ratio CoS@carbon nanocage: polytetrafluoroethylene: acetylene blac...

Embodiment 3

[0034] A method for preparing CoS@carbon nanocages: specifically comprising the following steps:

[0035] 1) Preparation of ZIF-67 precursor: 0.6 g of Co(NO 3 ) 2 •6H 2 The 2-methylimidazole of O and 6.5g is dissolved in the deionized water of 6ml and 21ml respectively, treats to completely dissolve after Co(NO 3 ) 2 •6H 2 The O solution was added dropwise to the 2-methylimidazole solution, and then 200 mg of polyvinylpyrrolidone (PVP) was added, stirred at 25 °C for 12 h, and the reaction product was washed with deionized water and ethanol for three times, then dried, The Co@carbon nanocages were obtained by calcination at 650℃ for 6 h in a tube furnace;

[0036] 2) Weigh 180 mg of Co@carbon nanocages and 40 mg of sulfur powder, mix and grind for 40 minutes, and roast the ground samples in a tube furnace at 450 °C for 5 hours to prepare CoS@carbon nanocages.

[0037] Lithium-ion battery assembly: by mass ratio CoS@carbon nanocage: polytetrafluoroethylene: acetylene blac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com