Tin carbon nanometer compound material for lithium ion battery and method for making same

A technology of nanocomposite materials and lithium-ion batteries, applied in electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve the problems of poor cycle performance of tin-carbon nanocomposite electrode materials, insufficient environmental protection of raw materials, complicated preparation process, etc., to achieve The effect of stable shape and structure, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1) With sodium stannate and cationic starch as initial raw materials, 7.5gNa 2 SnO 3 2H 2 O was prepared into a solution of 2 mol / L, and 5.0 g of cationic starch was added to the solution. After the resulting mixed solution was stirred evenly, it was heated while stirring until the water was evaporated to dryness, and then dried at 120° C. for 12 hours to obtain a mixture;

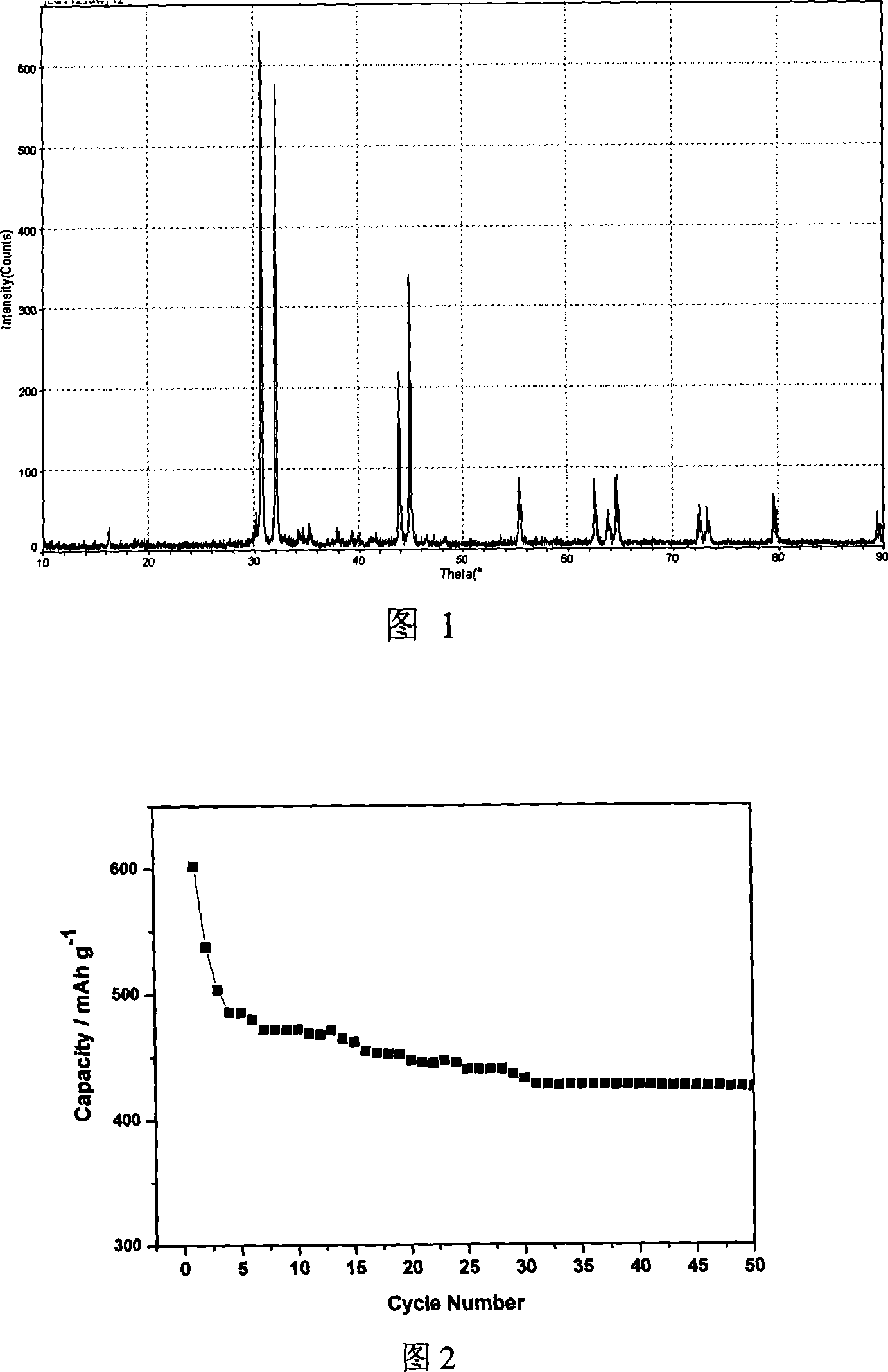

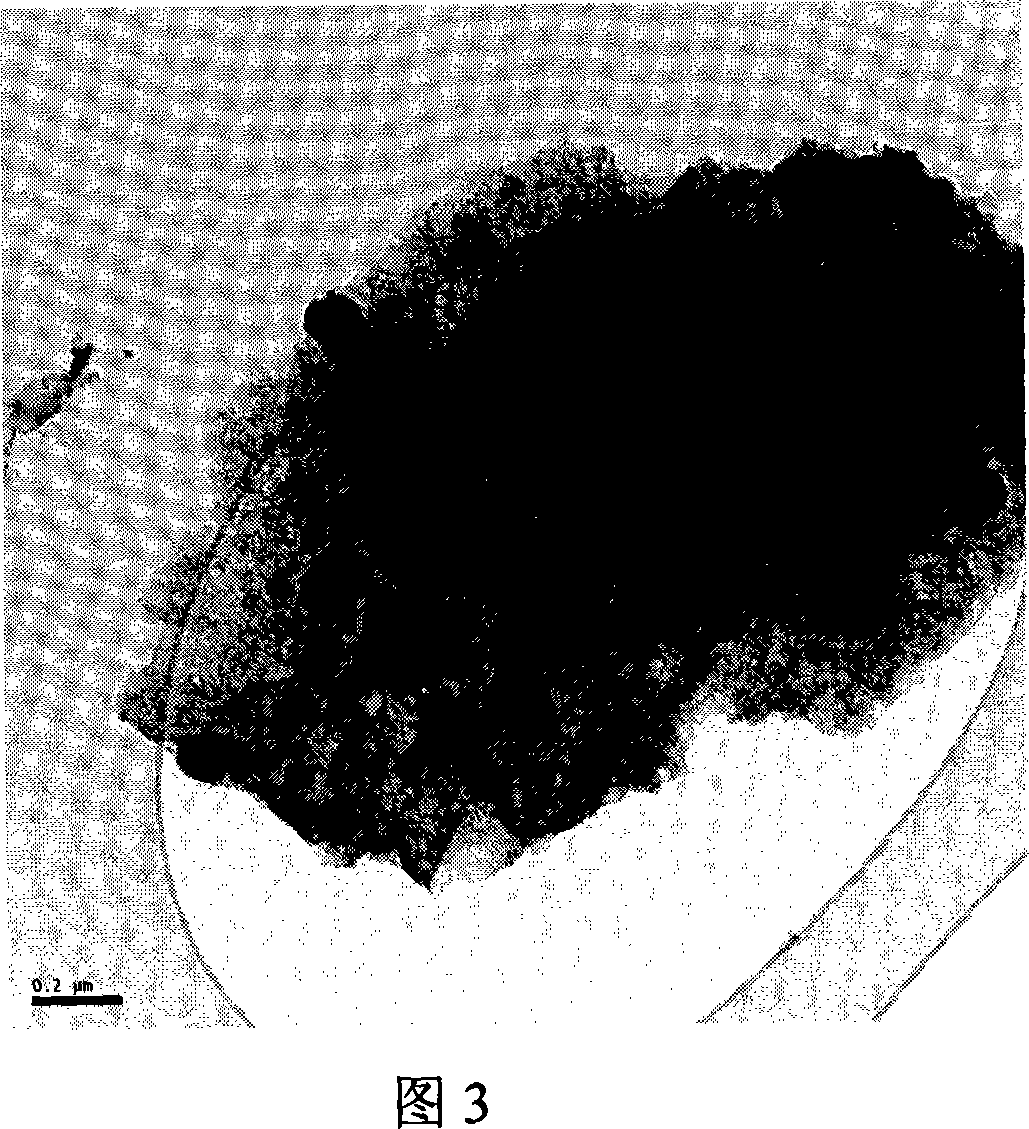

[0015] 2) The resulting mixture was heated to 400°C at 2°C / min in a flowing argon atmosphere (the flow rate of argon was 300ml / min) and kept at 400°C for 4 hours, then raised to 600°C at the same rate and kept for 4 hours, Then wait for it to cool naturally to room temperature, the obtained product is first washed with 5wt% hydrochloric acid to remove the sodium salt therein, and then washed to neutrality with distilled water, and the washed product is dried and ground through a 300-mesh sieve to obtain the lithium-ion battery negative electrode The tin-carbon nanocomposite material is used, its X...

Embodiment 2

[0018] 1) With tin chloride and cornstarch as initial raw materials, 5.6gSnCl 4 ·5H 2 O was prepared into a solution of 2 mol / L, and 5.0 g of cornstarch was added to the solution. After the resulting mixed solution was stirred evenly, it was heated while stirring until the water was evaporated to dryness, and then dried at 150° C. for 12 hours to obtain a mixture;

[0019] 2) In a flowing argon atmosphere (the flow rate of argon is 300ml / min), the resulting mixture was heated to 400°C at 2°C / min and kept for 4 hours, and then heated to 800°C at the same rate and kept for 10 hours. Then wait for it to cool naturally to room temperature, and grind the obtained product through a 300-mesh sieve to obtain the tin-carbon nanocomposite material for the negative electrode of the lithium ion battery.

[0020] The above-mentioned lithium-ion battery negative electrode is made of tin-carbon nanocomposite material plus 10wt% conductive agent acetylene black, 10wt% binder PVDF to make a s...

Embodiment 3

[0022] 1) take tin protochloride and tapioca starch as initial raw material, in 6.8gSnCl 2 2H 2 O and 5.0g of tapioca starch were mixed with 20ml of ethanol, ball milled at a rate of 500 rpm for 14 hours, then dried at 120°C for 6 hours to obtain the mixture;

[0023] 2) The resulting mixture is heated up to 400°C at 2°C / min in a flowing argon atmosphere (the flow rate of argon is 2000ml / min) and kept at a temperature of 4 hours, then heated to 1000°C at the same rate, and then allowed to cool naturally After reaching room temperature, the obtained product is ground and passed through a 300-mesh sieve to obtain the tin-carbon nanocomposite material for lithium-ion battery negative electrodes.

[0024] The above-mentioned lithium-ion battery negative electrode is made of tin-carbon nanocomposite material plus 10wt% conductive agent acetylene black, 10wt% binder PVDF to make a slurry, evenly coated on the copper foil, dried and compacted to form a round shape The pole piece is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com