Three-dimensional molybdenum disulfide nanoflower-graphene composite material and application thereof

A molybdenum disulfide, composite material technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of improving catalytic activity, reducing electrical resistance, and improving electron conduction and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

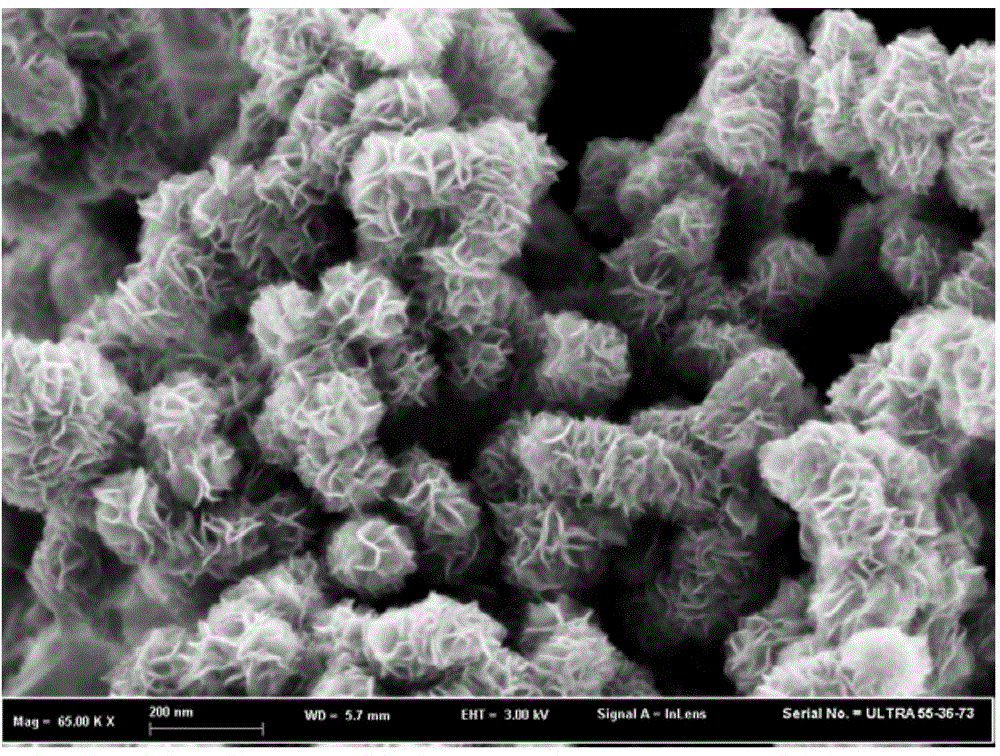

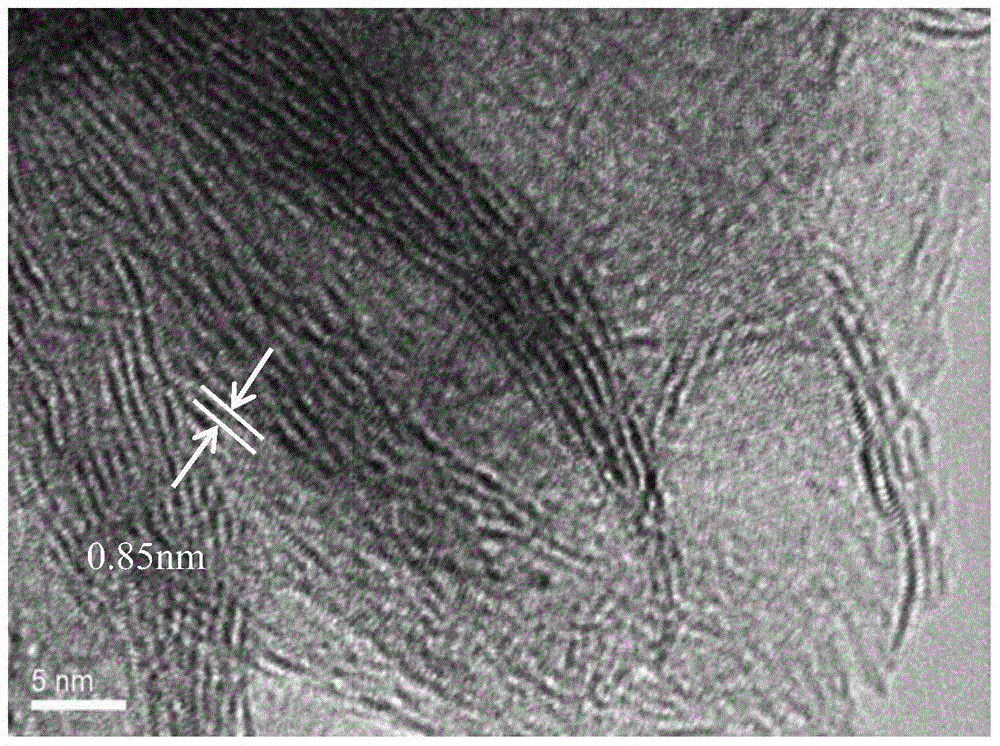

[0019] Example 1: This example prepares a three-dimensional molybdenum disulfide nanoflower-graphene composite material, which specifically includes the following steps:

[0020] (1) Add 10 mg of prepared graphene oxide powder (GO) into a reagent bottle containing 10 mL of N,N dimethylformamide, and ultrasonicate for half an hour to uniformly disperse graphene in N,N dimethylformamide formamide (DMF) to obtain a graphene oxide suspension:

[0021] (2) Weigh 20 mg of ammonium thiomolybdate with an electronic balance, and add it to the graphene oxide suspension in step 1. Sonicate for 10 minutes to dissolve;

[0022] (3) Add the solution in step 2 into a 25mL tetrafluoroethylene reactor, and react at 190°C for 15h;

[0023] (4) Add ethanol to the black product obtained from the reaction in step 3, centrifuge and wash it, repeat 5 times for 8 minutes each time, and dry it in vacuum at 60°C for 24 hours to obtain a three-dimensional molybdenum disulfide nanoflower-graphene compo...

Embodiment 2

[0025] Example 2, this example uses the three-dimensional molybdenum disulfide nanoflower-graphene composite material prepared in Example 1 to prepare a glassy carbon electrode, specifically: adding 3 mg of the dried three-dimensional molybdenum disulfide nanoflower-graphene composite material to Add 1.5mL of deionized water-ethanol mixture with a volume ratio of (3:1), and add 120uL of 5wt% Nafion solution, and obtain a suspension after ultrasonication for half an hour. Then use a pipette gun to measure 5uL of the suspension and drop-coat it on the glassy carbon electrode, and dry it naturally to obtain a molybdenum disulfide-graphene modified glassy carbon electrode.

Embodiment 3

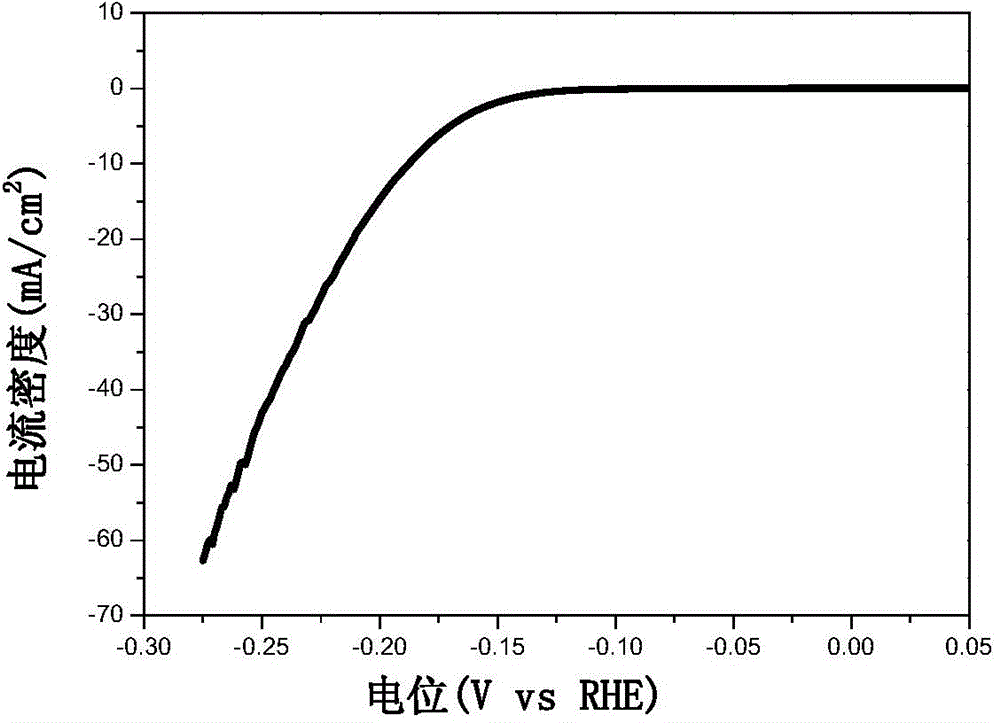

[0026] Embodiment 3: The electrode prepared in embodiment 2 is applied to electrochemical hydrogen evolution, specifically:

[0027] Three-dimensional molybdenum disulfide nanoflower-graphene composite modified glassy carbon electrode (GCE) as working electrode (WE), saturated calomel electrode as reference electrode (RE), platinum wire as counter electrode (CE) to form three electrodes system, with 0.5M sulfuric acid as the electrolyte. Before performing the electrochemical test, a saturated nitrogen gas was passed through to remove the oxygen in the solution. And calibrate the electrode positive SCE=RHE+0.267V. image 3 For the polarization curves (Polarization curves) of the three-dimensional molybdenum disulfide nanoflower-graphene composite prepared for the present invention, it can be seen from the figure that when the overpotential is 250mV, the current density reaches 43mA / cm 2 , converted into a mass current density of 304A / g. Figure 4 The stability test curve (Du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com