Fluorinated graphene electrode active material and preparation method and application thereof

An electrode active material, a technology of fluorinated graphene, which is applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., can solve the problem of poor multiplier performance of fluorinated graphene lithium batteries, which does not meet the development orientation of green energy, and the peeling off of fluorinated graphite Poor effect and other problems, to achieve the effect of accelerating the transmission speed, promoting the kinetic process of the electrode, and facilitating the conduction of electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the fluorinated graphene electrode active material provided by the invention comprises the following steps:

[0037] Step S1, preparing graphite fluoride dispersion:

[0038] Weigh the fluorinated graphite raw material, add it to the cationic surfactant aqueous solution, and mix evenly to obtain the fluorinated graphite dispersion, the mass ratio of the fluorinated graphite to the cationic surfactant is 1.2-1.6;

[0039] Step S2, preparing graphene fluoride solution:

[0040] The fluorinated graphite dispersion and zirconia balls obtained in step S1 are sand-milled, and then left to stand for 12-24 hours to obtain a fluorinated graphene solution;

[0041] Step S3, preparing electrode active material:

[0042] Add ethanol to the fluorinated graphene solution obtained in step S2, mix evenly, centrifuge, discard the supernatant, repeat the above operation 4-8 times, then use deionized water to filter, wash and freeze-dry to obtain fluorinated grap...

Embodiment 1

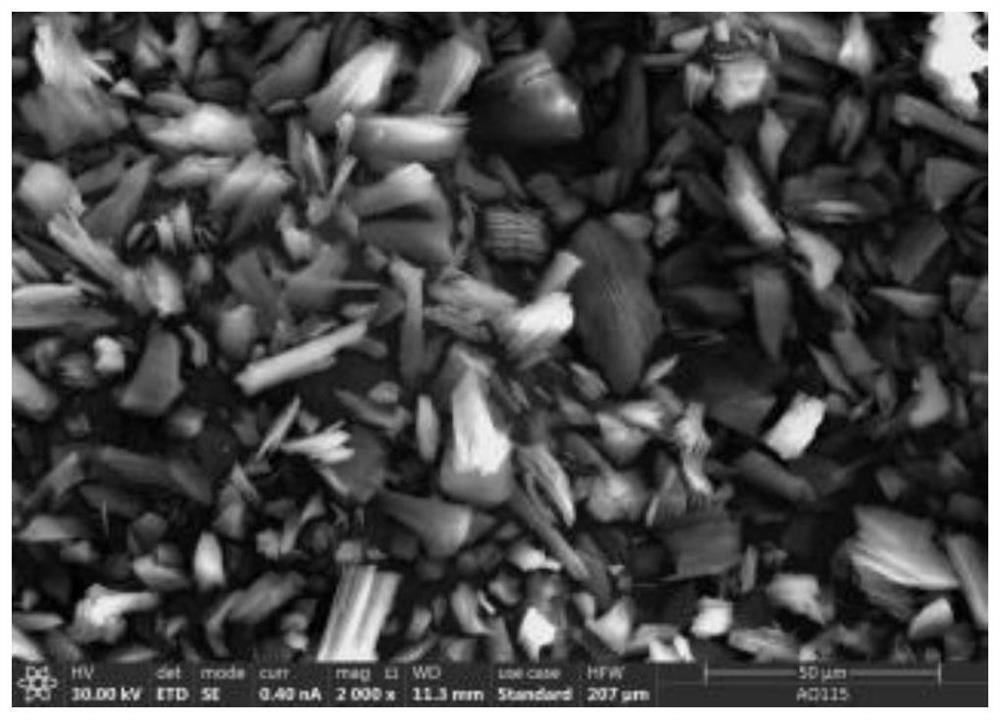

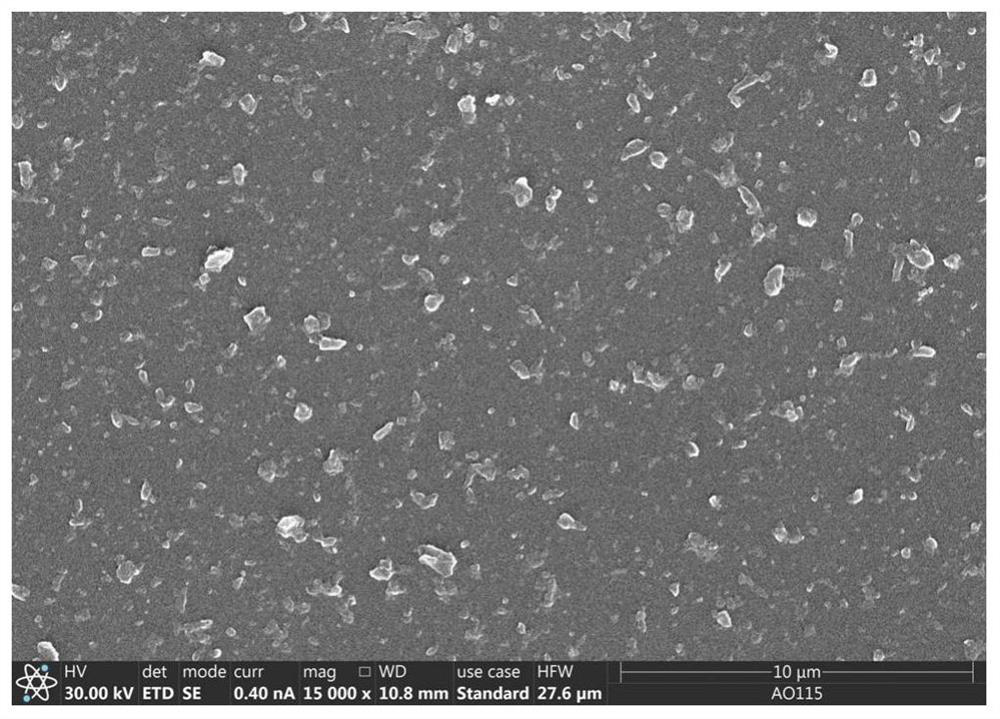

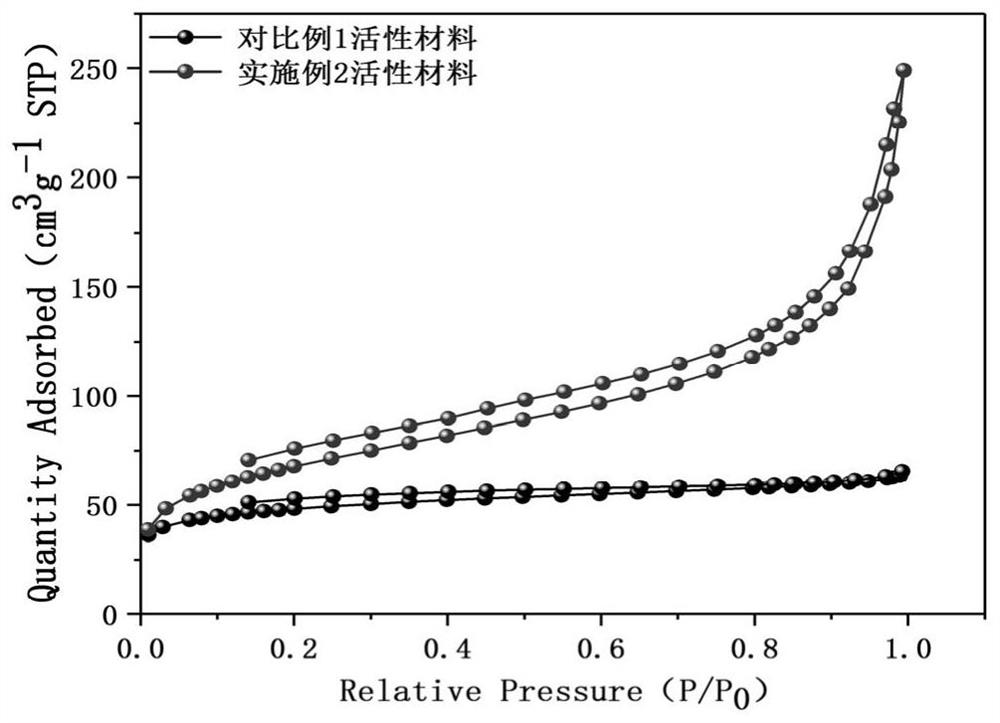

[0058] Disperse 9 g of cetyltrimethylammonium bromide (CTAB) into 1.5 L of deionized water and stir for 1 h. Dissolve and disperse 15g of raw material fluorinated graphite (F / C=0.9) in 1.5L of cationic surfactant solution, stir for 4.5h to disperse the fluorinated graphite evenly, and the cationic surfactant is evenly inserted between the layers of the fluorinated graphite, then add In a ball mill, shear and peel continuously for 2 hours to obtain a fluorinated graphene solution with reduced size and thinner thickness. Measure 1000mL of graphene fluoride aqueous solution, add 500mL of ethanol, and disperse the same mass into a centrifuge tube, centrifuge at 8000rpm for 10min, add the same amount of water and ethanol, and repeat the operation 8 times to remove a large amount of CTAB. Finally, pour it into a vacuum filter bottle, add a large amount of deionized water to wash it, and obtain the fluorinated graphene, put it into a freeze dryer and freeze-dry it for 12 hours, and o...

Embodiment 2

[0060] Disperse 12 g of cetyltrimethylammonium bromide (CTAB) into 1.5 L of deionized water and stir for 1 h. Dissolve and disperse 15g of raw material fluorinated graphite (F / C=0.9) in 1.5L of cationic surfactant solution, stir for 6h to disperse the fluorinated graphite evenly, the cationic surfactant is evenly inserted between the fluorinated graphite layers, and then add it to the ball mill During continuous shearing and peeling for 4 hours, a fluorinated graphene solution with reduced size and thinner thickness was obtained. Measure 1000mL fluorinated graphene aqueous solution, add 500mL ethanol, and disperse the same mass into a centrifuge tube, centrifuge at 10000rpm for 10min, add the same amount of water and ethanol, and repeat the operation 12 times to remove a large amount of CTAB. Finally, pour it into a vacuum filter bottle, add a large amount of deionized water to wash it, and obtain the fluorinated graphene, put it into a freeze dryer and freeze-dry it for 12 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com