Ultrasonic sensor

A sensor and ultrasonic technology, used in bumpers, transportation and packaging, vehicle parts, etc., can solve the problems of limited thickness range of bumpers, inability to install, poor versatility, etc., to achieve a wide range of thicknesses, high installation efficiency, and large operating space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

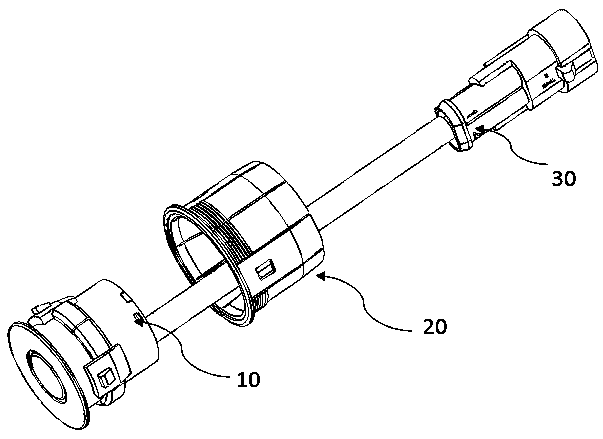

[0024] Such as figure 1 As shown, the ultrasonic sensor disclosed in this embodiment includes a sensor body 10 and a sensor bracket 20 , and the sensor body 10 has a wire harness 30 .

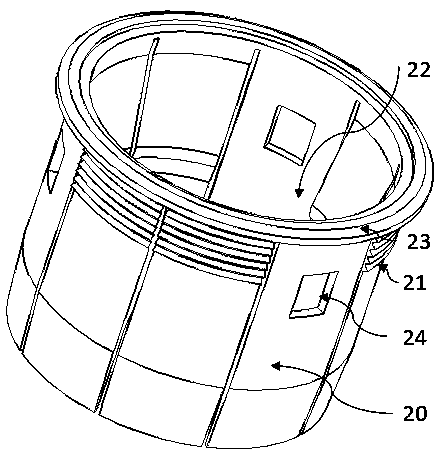

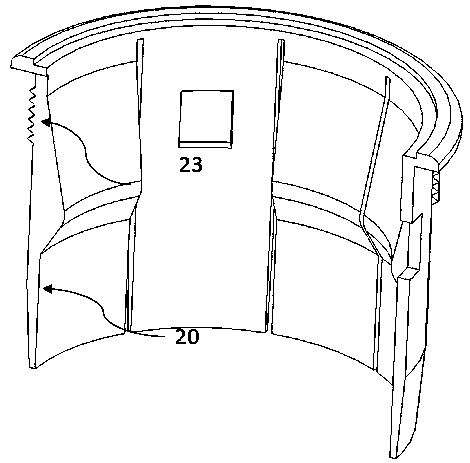

[0025] Such as figure 2 and 3 As shown, the sensor bracket 20 is a symmetrical rotator structure composed of several claws 22, and one end of each claw head is connected by a bracket flange 23. Among the several claws 22, there are Class I claws and Class II claws. Claws, type I claws are provided with a rib structure 21 on the surface near the bracket flange 23, and type II claws are provided with bracket slots 24 at the end close to the bracket flange 23; the number of the type I claws is not less than four, The rib structures 21 on a single type I claw are arranged in the axial direction, and the number is not less than five. The rib structure 21 is one of hard elastic materials such as silicon, rubber, plastic or metal shrapnel, and its shape is arc-shaped or triangular.

[0026] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com