Foam rotary knife for structural heat preservation board

A technology of structural insulation boards and rotary knives, which is applied in metal processing and other directions, can solve the problems of not being able to control the size well, reduce work efficiency, and affect the appearance, and achieve the effects of wide thickness range, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

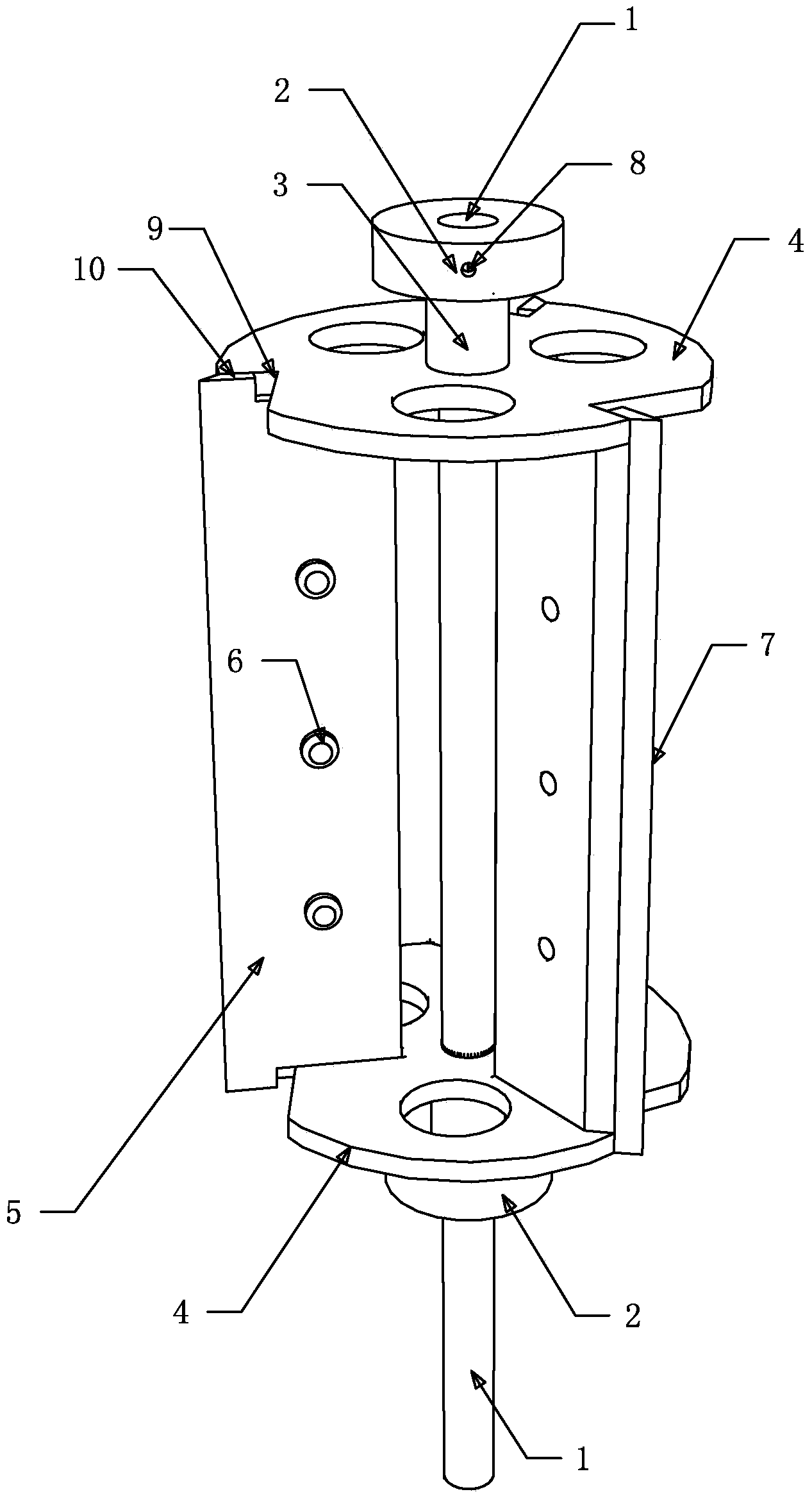

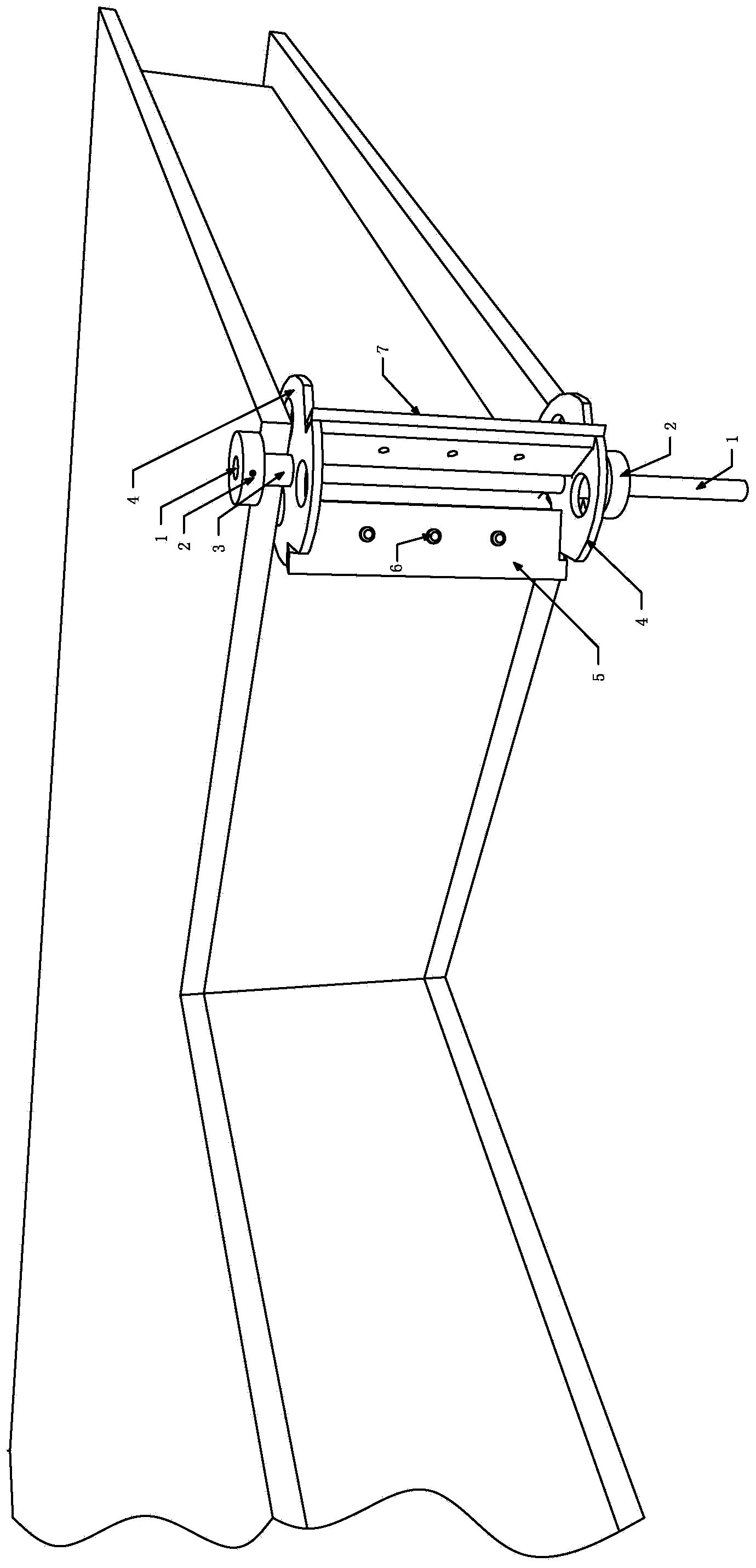

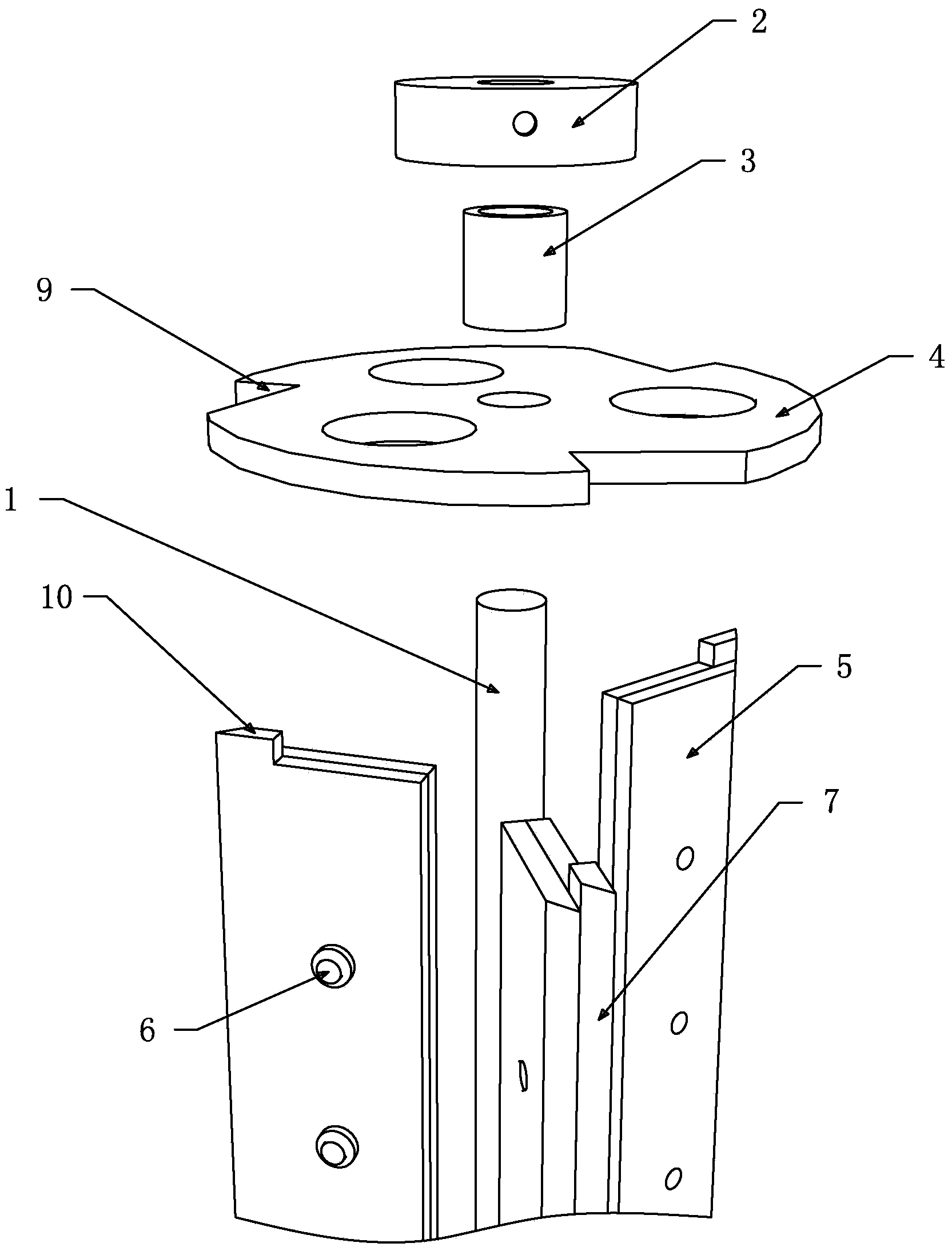

[0027] Such as figure 1 , figure 2 , image 3 and Figure 4 A foam rotary knife for a structural insulation board is shown, including a mandrel 1, a stopper 2, a bearing 3, a fixed plate 4 and a blade 7;

[0028] The stopper 2 is sleeved and assembled on the top end of the mandrel 1, and is connected and fixed with the mandrel 1 through the radial assembly screw 8 and the mandrel 1 (the stopper 2 and the mandrel 1 can also be threadedly connected and locked by a nut way to realize the assembly of stopper 2 and mandrel 1);

[0029] The bearing 3 is sleeved and assembled on the mandrel 1, and the bearing 3 is in contact with the lower end surface of the head 2; the diameter of the head 2 is larger than that of the bearing 3;

[0030] The fixed plate 4 is a disc, and is sleeved and assembled on the mandrel 1 and close to the lower end of the bearing 3;

[0031] The fixed plate 4, the bearing 3 and the stopper 2 are assembled in pairs, that is, the other end of the mandrel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com