Wide-width continuous fiber enhanced thermoplastic coiled material as well as preparation method and equipment thereof

A technology for reinforcing thermoplastic and continuous fibers, used in chemical instruments and methods, synthetic resin layered products, lamination devices, etc. The effect of good tension and wide width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

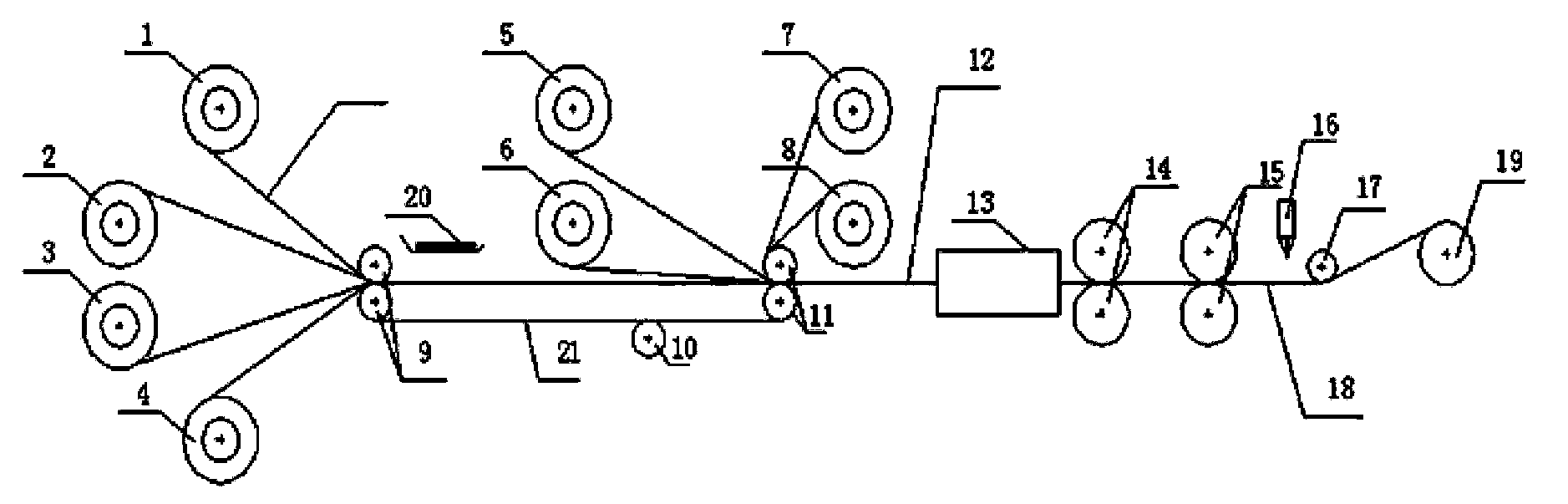

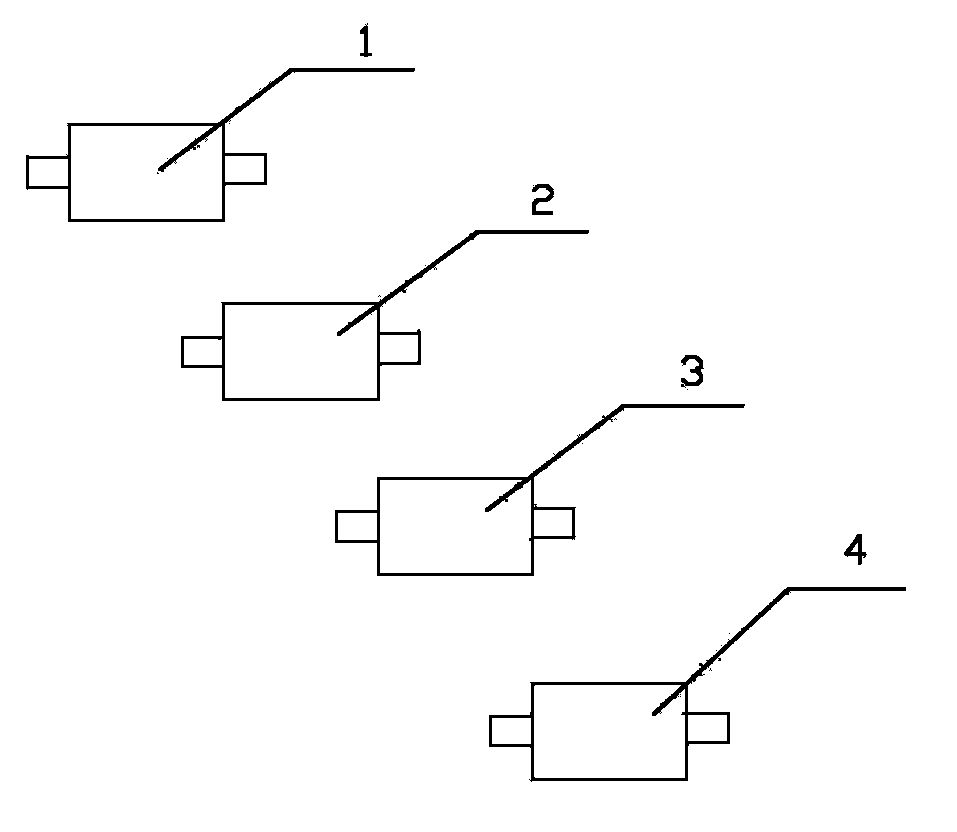

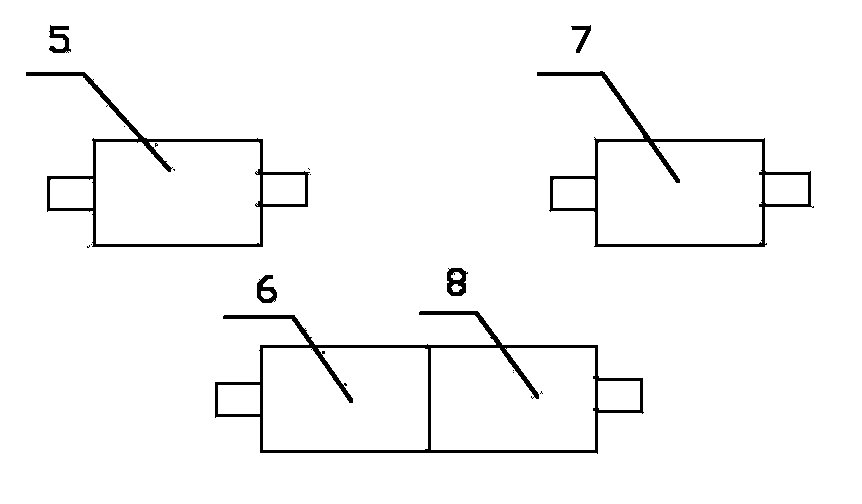

[0029] like Figure 1~3 Shown, a kind of preparation equipment of wide-width continuous fiber-reinforced thermoplastic coil, this equipment comprises the first prepreg roll set, the second prepreg roll set, the first pinch roll 9, the second pinch roll 11, Horizontal laying material box 20, conveyor belt 21, transmission support roller 10, oven 13, first rolling mill 14, second rolling mill 15, cross shear 16, transmission roller 17 and winder 19, the first prepreg roller group consists of 4 The first prepreg roll 1, the second prepreg roll 2, the third prepreg roll 3 and the fourth prepreg roll 4 are arranged staggered in the transverse direction, and the second prepreg roll group consists of 4 transverse The fifth prepreg roll 5, the sixth prepreg roll 6, the seventh prepreg roll 7, and the eighth prepreg roll 8 are arranged staggered in the direction to ensure the vertical seamless splicing of the drawn prepreg tape. One prepreg roll set is located before the first pinch r...

Embodiment 2

[0034] The method for preparing a wide-width continuous fiber-reinforced thermoplastic coil using the equipment described in Example 1 comprises the following steps;

[0035]Lead the narrow prepreg tape from the first prepreg roll 1, the second prepreg roll 2, the third prepreg roll 3 and the fourth prepreg roll 4 at a speed of 1.8m / min to The first pinch roller 9 is seamlessly spliced at the first pinch roller 9 to form the bottom layer of the prepreg tape of required width, and then passes through the conveyor belt 21 to obtain the transverse prepreg tape in the horizontal laying material box 20 above the conveyor belt 21 , horizontally and seamlessly laid on the bottom layer of the prepreg tape to form the middle layer of the prepreg tape, the fifth prepreg roll 5, the sixth prepreg roll 6, and the seventh prepreg roll staggered from the rear end of the conveyor belt 21 7 and the eighth prepreg roll 8 lead out the narrow prepreg tape and splice seamlessly at the second pi...

Embodiment 3

[0038] Utilize the method described in embodiment 1 to prepare wide-width continuous fiber reinforced thermoplastic coil, comprise the following steps:

[0039] Lead the narrow prepreg tape from the first prepreg roll 1, the second prepreg roll 2, the third prepreg roll 3 and the fourth prepreg roll 4 to the first prepreg roll at a speed of 3m / min. A pinch roller 9 is seamlessly spliced at the first pinch roller 9 to form the bottom layer of the prepreg tape of required width, and then passes through the conveyor belt 21 to obtain the transverse prepreg tape in the horizontal laying material box 20 above the conveyor belt 21, Horizontally seamlessly lay 2 layers on the bottom layer of the prepreg tape to form the middle layer of the prepreg tape. The fifth prepreg roll 5, the sixth prepreg roll The prepreg roll 7 and the eighth prepreg roll 8 lead out the narrow prepreg tape and splice seamlessly at the second pinch roll 11 to form a required wide prepreg surface layer and l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com