Wide width continuous fiber reinforced thermoplastic plastic coiled material and preparation method and device thereof

A technology of reinforced thermoplastic and continuous fiber, which is applied in the field of materials, can solve the problems of mechanical properties and appearance, complex processing technology, etc., and achieve the effect of wide thickness range, good continuous tension and wide width range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

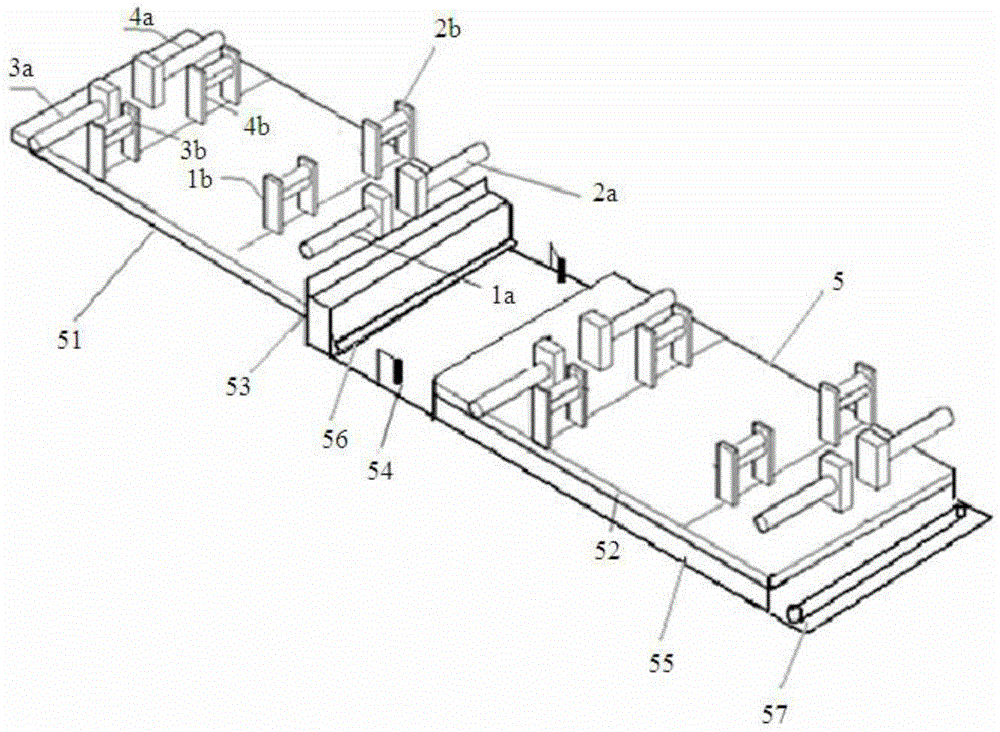

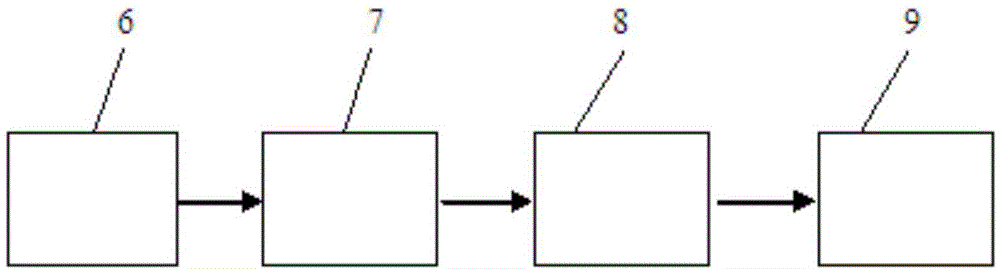

[0065] Such as Figure 1~4 A device for preparing wide-width continuous fiber-reinforced thermoplastic coils is shown, which includes an uncoiling part 6 , a heating and melting part 7 , a rolling part 8 and a winding part 9 from left to right.

[0066] Unwinding part 6 comprises unwinding platform base 5, as figure 1 As shown, the left side of the uncoiling platform base is provided with a first uncoiling unit 51, the middle part of the uncoiling platform base is provided with a horizontal material box 53, and the right side of the horizontal material box 53 is provided with a position control roller 56, and the right side of the position control roller 56 A welding device 54 is provided on the side, a second uncoiling unit 52 is provided on the right side of the uncoiling platform, a position control roller 57 is provided on the right side of the second uncoiling unit 52, and a roller 57 is provided below the second uncoiling unit 52 for the left side material to pass throug...

Embodiment 2

[0086] A kind of equipment for preparing wide-width continuous fiber-reinforced thermoplastic coils similar to that in Example 1, the difference is that the first uncoiling unit 51 and the second uncoiling unit 52 respectively include 10 feeding units, and the welding device 54 is a heating The air gun, the heating and melting part 7 is a heating furnace, and the others are the same.

[0087] A preparation of wide-width continuous fiber-reinforced thermoplastic coils prepared by the above-mentioned equipment comprises the following steps:

[0088] (1) Opening and laying:

[0089] 20 rolls of narrow prepreg tapes with a width of 300 mm and a thickness of 0.3 mm are loaded into the first uncoiling unit 51 and the second uncoiling unit 52 respectively, and are respectively seamlessly spliced longitudinally to form the first longitudinal layer and the second longitudinal layer;

[0090] When the first longitudinal layer passes through the horizontal paving material box 53, the ...

Embodiment 3

[0096] A kind of equipment for preparing wide-width continuous fiber-reinforced thermoplastic coils similar to that in Example 1, the difference is that the first uncoiling unit 51 and the second uncoiling unit 52 respectively include 10 feeding units, and the welding device 54 is a heating The air gun, the heating and melting part 7 is a heating furnace, and the others are the same.

[0097] A preparation of wide-width continuous fiber-reinforced thermoplastic coils prepared by the above-mentioned equipment comprises the following steps:

[0098] (1) Opening and laying:

[0099] 20 rolls of narrow prepreg tapes with a width of 300 mm and a thickness of 0.3 mm are loaded into the first uncoiling unit 51 and the second uncoiling unit 52 respectively, and are respectively seamlessly spliced longitudinally to form the first longitudinal layer and the second longitudinal layer;

[0100] When the first longitudinal layer passes through the horizontal paving material box 53, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com