Titanium-series cathode active material and preparation method thereof, titanium-series lithium ion power battery

A negative electrode active material, titanium-based technology, applied in the field of lithium-ion power batteries, titanium-based negative electrode materials and their preparation, can solve the problems of poor product consistency, no indication of charging end, high rate performance improvement, etc., and achieve a wide range of operating temperatures , Good battery processing performance, good effect of large rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the titanium-based negative electrode active material of the present invention comprises the following steps:

[0031] 1. According to the molar ratio of lithium in inorganic lithium salt: titanium dioxide: doping modifier: 1.9-2.1: 4.9-5.1: greater than 0-10, after mixing, use high-speed stirring or ball milling method, speed 100-500r / min, grind Disperse for 2 to 40 hours to prepare a composite lithium titanate precursor mixture, that is, Li 4 Ti 5 o 12 with M x Inorganic lithium salts are lithium hydroxide, lithium carbonate, lithium acetate, lithium chloride, lithium sulfate, lithium nitrate, lithium iodide, lithium tert-butoxide, lithium benzoate, lithium formate, lithium fluoride, lithium chromate , lithium citrate tetrahydrate, lithium tetrachloroaluminate, lithium bromide, lithium tetrafluoroborate or lithium oxalate, the doping modifier is metal element Al, Mg, Cu, Ag, Ni, Co, Mn, Cd, Pb, Bi , Sn, Ge, metal compounds alumina, magnes...

Embodiment 1

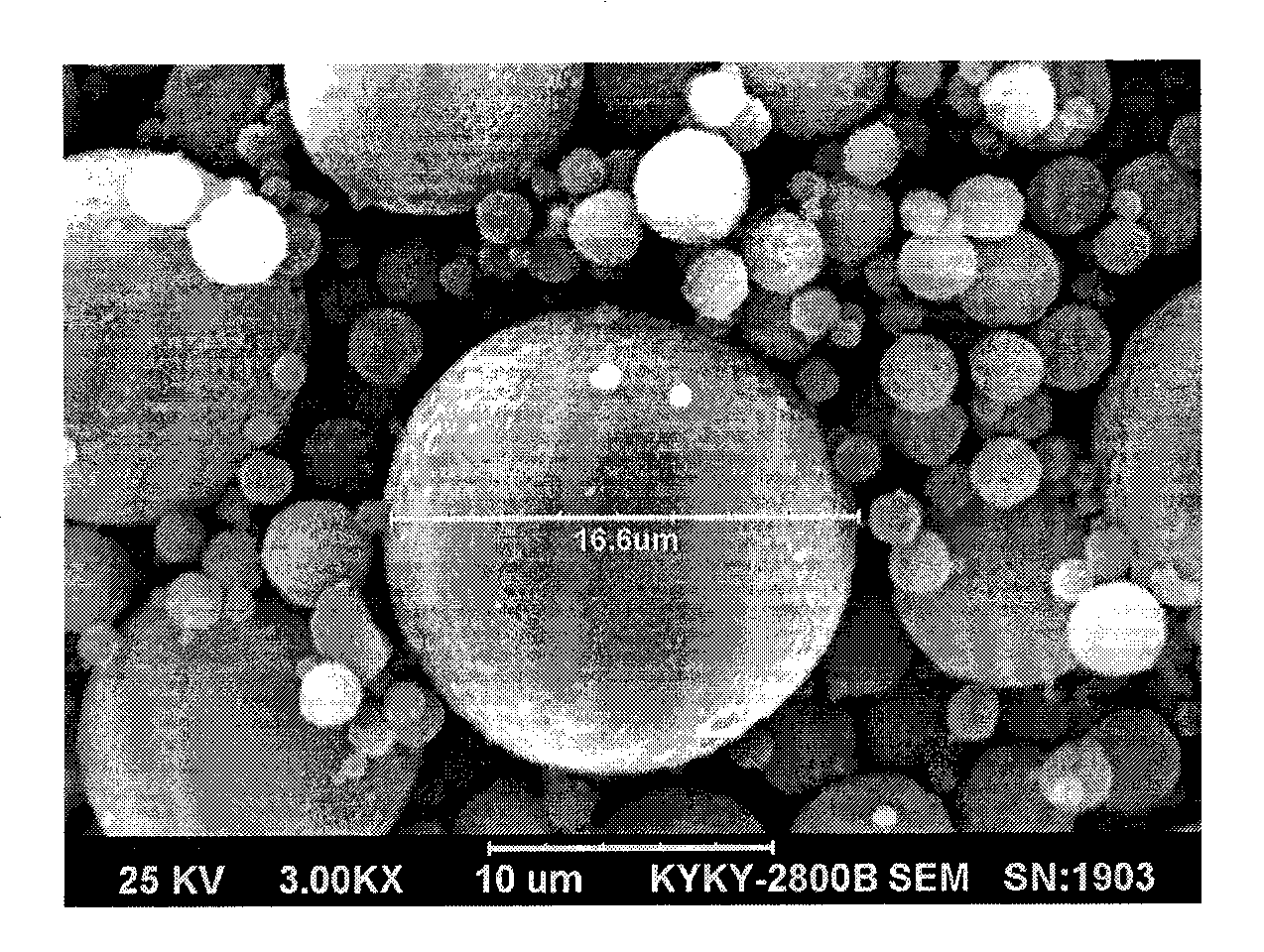

[0037] Example 1: 2mol of lithium carbonate, 5mol of titanium dioxide, 0.1mol of nano-sized copper oxide powder, 4mol of nano-carbon, and a rotation speed of 300r / min were ground and dispersed for 16 hours to obtain a composite lithium titanate precursor mixture; the composite lithium titanate precursor mixture Disperse in ethanol, the ratio of solid to organic solvent is 1.5:1, and spray dry at 150°C to obtain dispersed powder; heat-treat the dispersed powder at a heating rate of 5°C / min in a temperature range of 700°C For 24 hours, nitrogen gas was introduced during the period, and naturally cooled to below 150 ° C; crushed and sieved to obtain Li with an average particle size of 10 μm 4 Ti 5 o 12 / CuO 0.1 (x=0.1) negative electrode active material. Such as figure 1 As shown, the lithium titanate material has spherical and spheroidal microscopic features, and the surface is smooth, such as Figure 6 As shown, the thickness of the nano-coating layer is about 8nm, and the...

Embodiment 2

[0040] Example 2: 2.1mol of lithium carbonate, 5.1mol of titanium dioxide, and 0.1mol of nano-scale alumina powder were ground and dispersed for 24 hours at a speed of 200r / min to prepare a composite lithium titanate precursor mixture; the composite lithium titanate precursor mixture was dispersed in In ethanol, the ratio of solid to organic solvent is 1.5:1, and the dispersed powder is obtained by spray drying at 250°C; the dispersed powder is heat-treated at a temperature of 400°C for 40 hours at a heating rate of 10°C / min , during which nitrogen gas was introduced, naturally cooled to below 150°C; crushed and sieved to obtain Li with an average particle size of 1 μm 4 Ti 5 o 12 / (Al 2 o 3 ) 0.1 (x=0.1) negative electrode active material.

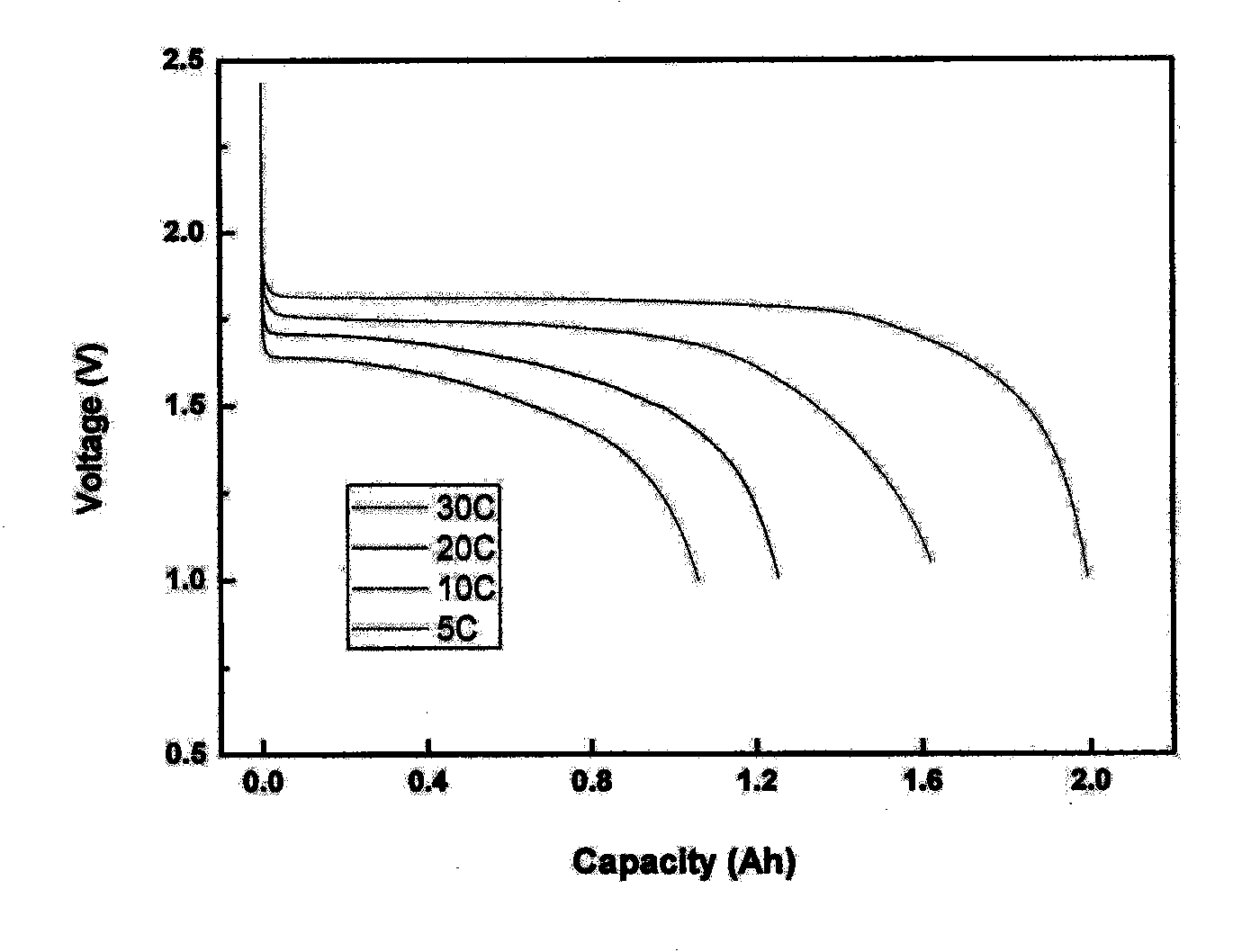

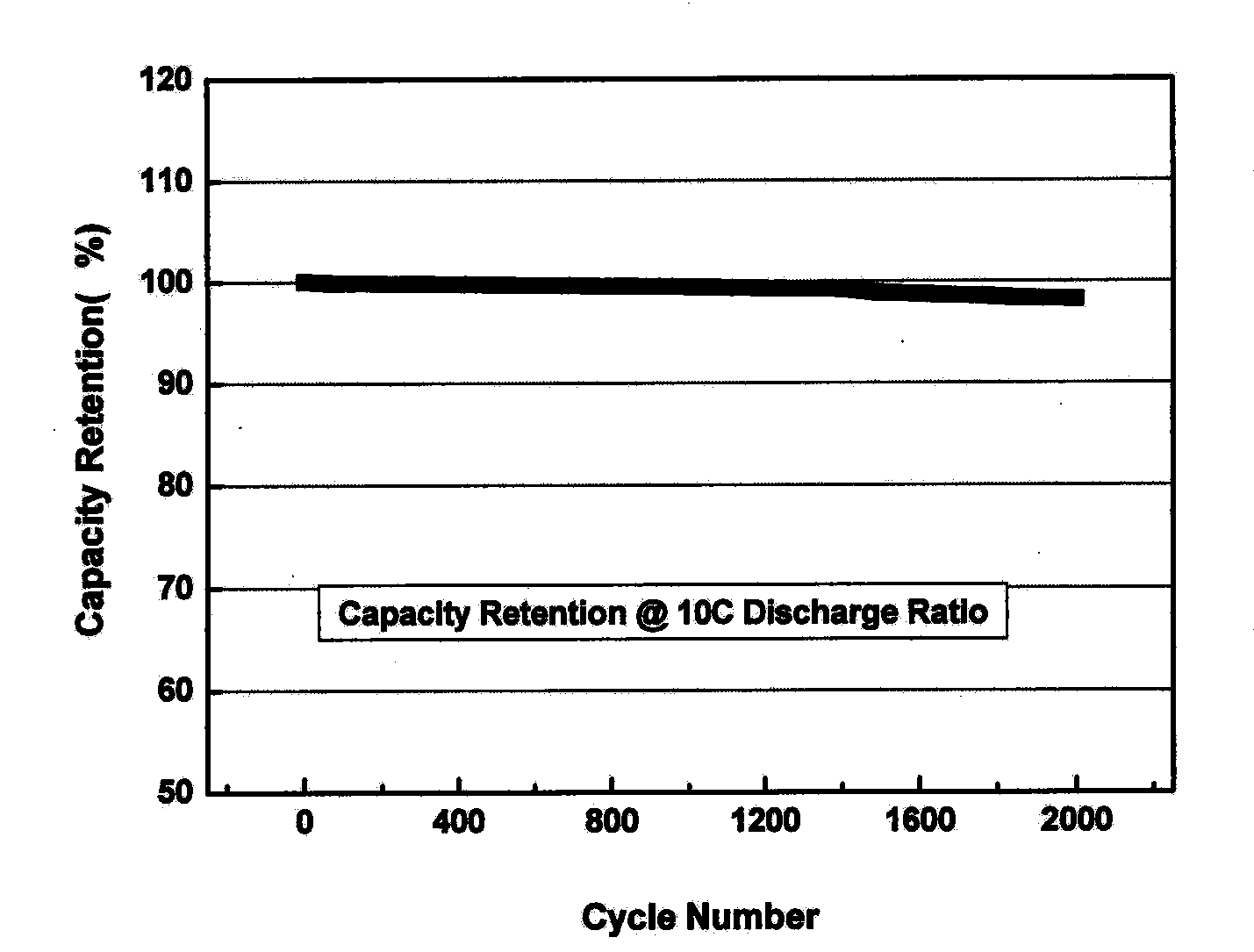

[0041] The negative electrode active material obtained above, the conductive agent acetylene black, and the binder PVDF are used in a mass ratio of 85%:10%:5% to make a negative electrode sheet. LiFePO 4 , Conductive agent acetylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com