A kind of multi-component doped lithium phosphate cathode material and preparation method thereof, and lithium ion power battery

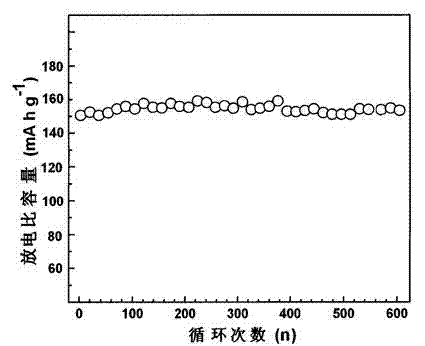

A positive electrode material, lithium phosphate technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle performance, low specific capacity of lithium phosphate, low specific capacity retention rate, etc., to avoid agglomeration, improve High rate capability, effect of improving electron conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of phosphate cathode material for lithium ion power battery of the present invention comprises the following steps:

[0032] (1) Lithium in the lithium source compound: iron in the iron source compound: titanium in the titanium source compound: manganese in the manganese source compound: ammonium dihydrogen phosphate according to 1: 1-x-y: 0.5x: 0.5x+y : Mixing in a molar ratio of 1, adding carbon or carbon source compounds at the same time, the addition of organic carbon source compounds is 1-10% of the total weight of the substrate raw materials to form a raw material mixture;

[0033] (2) Disperse the raw material mixture in water or ethanol or acetone solvent, the mass ratio of solid to solvent is 1:1.5-2.5, ball mill and disperse in a high-energy ball mill at a speed of 200-1000 r / min for 15-25 hours, and The obtained suspension is spray-dried by a high-speed centrifugal spray dryer to prepare a precursor dispersion; this process step is bene...

Embodiment 1

[0040] (1) Mix lithium hydroxide: ferrous chloride: titanium trichloride: manganese oxalate: ammonium dihydrogen phosphate according to the molar ratio of 1:0.96:0.01:0.08:1, and add citric acid and citric acid The addition amount is 3% of the total weight of the substrate raw materials (that is, the total weight of lithium source, iron source, titanium source, titanium source, manganese source and ammonium dihydrogen phosphate) to form a raw material mixture;

[0041] (2) Disperse the raw material mixture in an ethanol solvent, the mass ratio of solid to solvent is 1:1.5, ball mill and disperse for 20 hours at a speed of 500 r / min in a high-energy ball mill, and pass the obtained suspension through a high-speed centrifugal spray The dryer is used for spray drying, the spray drying inlet temperature is 220°C, the outlet temperature is 50°C, and the feeding speed is: 50 ml / min to prepare the precursor dispersion;

[0042] (3) in N 2 In the atmosphere, the temperature of the pr...

Embodiment 2

[0048] (1) Mix lithium hydroxide: ferrous chloride: titanium trichloride: manganese oxalate: ammonium dihydrogen phosphate according to the molar ratio of 1:0.9:0.01:0.02:1, and add glucose at the same time, the amount of glucose added 3% of the total weight of the substrate raw materials (i.e. the total weight of lithium source, iron source, titanium source, titanium source, manganese source and ammonium dihydrogen phosphate) to form a raw material mixture;

[0049] (2) Disperse the raw material mixture in ethanol solvent, the mass ratio of solid to solvent is 1:2, ball mill and disperse in a high-energy ball mill at a speed of 500 r / min for 20 hours, and the obtained suspension is spray-dried by high-speed centrifugal The spray drying machine is used for spray drying, the spray drying inlet temperature is 200°C, the outlet temperature is 50°C, and the feeding speed is: 50 ml / min to prepare the precursor dispersion;

[0050] (3) in N 2 In the atmosphere, the temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com