Composite lithium oxide film and preparation method and application thereof

A lithium oxide and composite technology, which is applied in the field of composite lithium oxide thin film and its preparation, can solve the problem of unsatisfactory electrochemical properties such as charge and discharge efficiency and specific capacity cycle of the positive electrode sheet, charge and discharge efficiency, specific capacity and cycle Unsatisfactory chemical properties and other problems, to prevent irreversible side reactions, reduce irreversible side reactions, and reduce stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] On the one hand, an embodiment of the present invention provides a method for preparing a composite lithium oxide thin film. The preparation method of the composite lithium oxide film comprises the following steps:

[0023] The lithium oxide target material and the energy density contributing host element target material are subjected to co-sputtering treatment in an inert atmosphere, and a composite lithium oxide film is grown on the substrate.

[0024] Wherein, in the co-sputtering process, the energy density contributes the host element target material to realize the doping of lithium oxide, so that the lithium oxide is grown on the substrate, and the energy density contributes the host element as the doping The film layer of the element, so that a larger surface area is formed in the composite lithium oxide film for lithium ions to be accommodated, so as to significantly reduce the interface resistance of the composite lithium oxide film. At the same time, because ...

Embodiment 1

[0038] Embodiment 1 provides a composite lithium oxide thin film and a preparation method thereof. The composite lithium oxide thin film is prepared according to a method comprising the following steps:

[0039] S11: Use a copper plate with a diameter of 70mm as the tray for the powder target material, sprinkle the lithium carbonate powder evenly on the tray, and use a 5-ton unidirectional press to dry press in one direction to obtain the lithium carbonate powder target material;

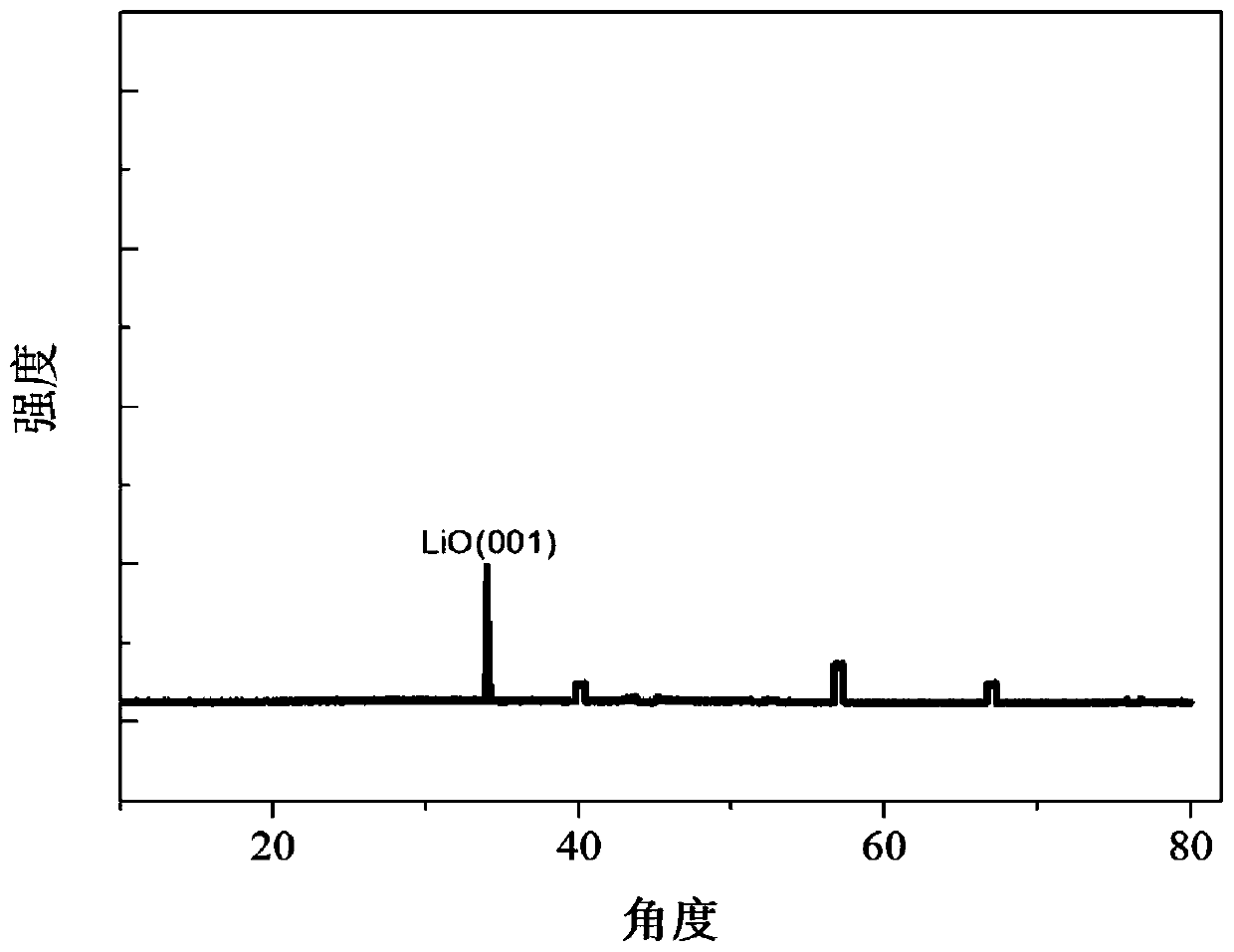

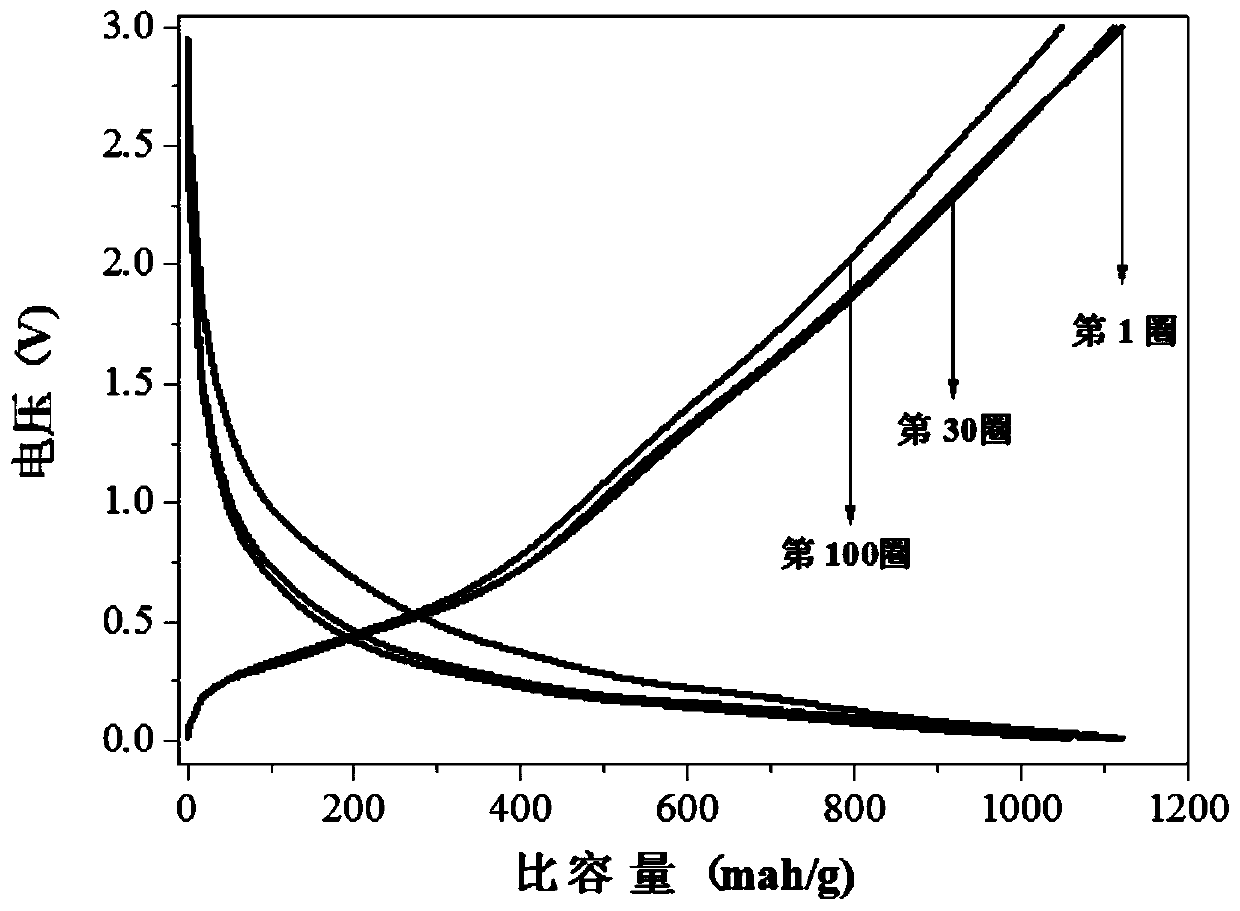

[0040] S12: Use the lithium carbonate powder target prepared in step S11 and the purchased silicon ceramic target with a purity of 99.999% as a sputtering source on a Japanese 304 stainless steel substrate with a distance of 50 mm between the substrate and the target at 1.0×10 -2 In a mixed atmosphere of high-purity argon and oxygen at millibars, Li 2 CO 3 :Si=2:1 power ratio co-sputtering method to prepare LiO with a thickness of 1 μm 2 - Si composite film; during deposition, the substrate was k...

Embodiment 2

[0043] Embodiment 1 provides a composite lithium oxide thin film and a preparation method thereof. The composite lithium oxide thin film is prepared according to a method comprising the following steps:

[0044] S11: Use a copper plate with a diameter of 70mm as the tray for the powder target material, sprinkle the lithium oxide powder evenly on the tray, and use a 5-ton unidirectional press to dry-press in one direction to obtain the lithium oxide powder target material;

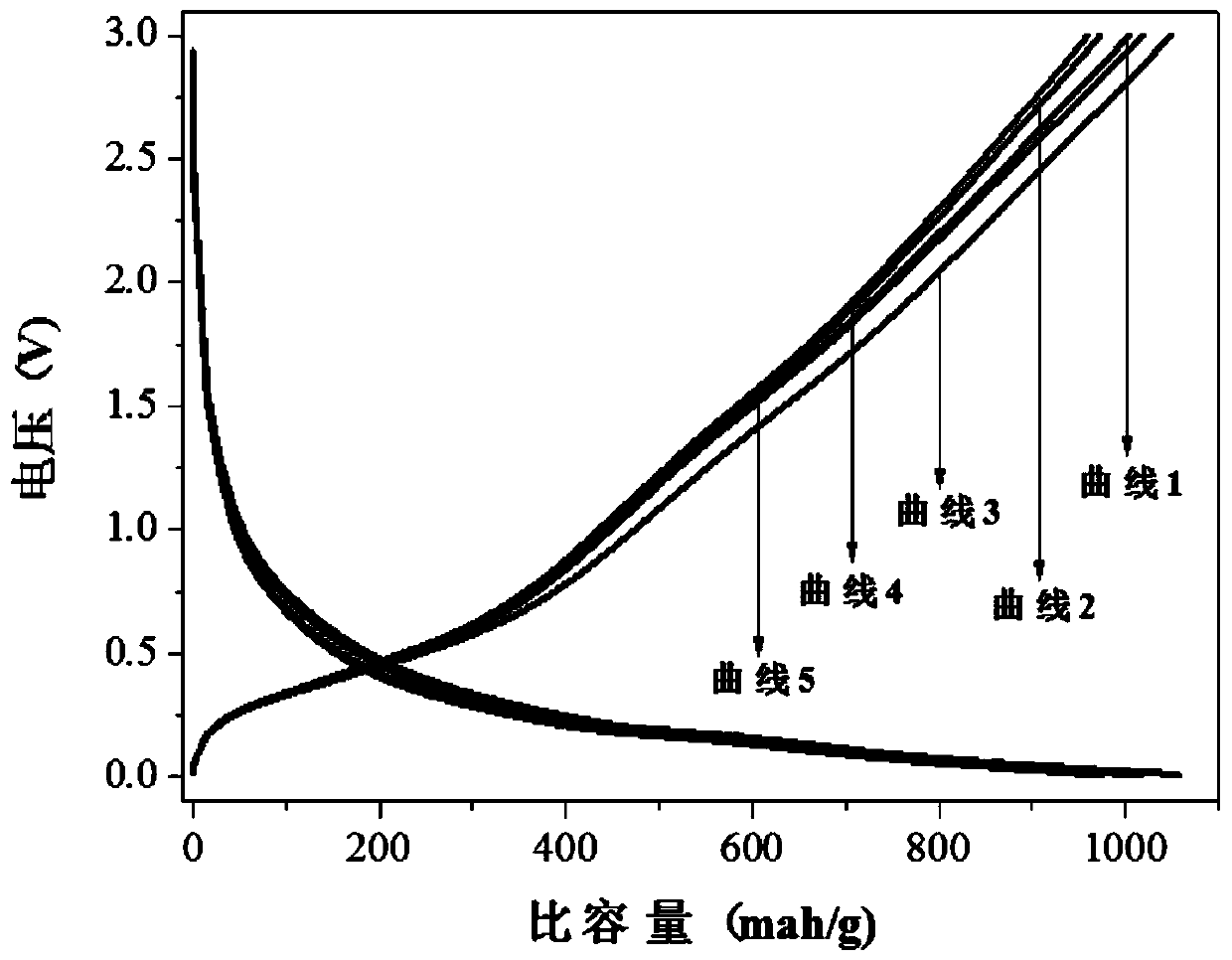

[0045] S12: The lithium oxide powder target prepared in step S11 and the purchased nickel ceramic target with a purity of 99.999% were used as sputtering sources on a Japanese 304 stainless steel substrate with a distance of 50 mm between the substrate and the target at 1.0×10 -2 In a mixed atmosphere of high-purity nitrogen and oxygen in millibars, LiO 2 :Ni=4:1 power ratio co-sputtering method to prepare LiO with a thickness of 1 μm 2 - Ni composite film; during deposition, the substrate was kept at 400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com